TM 9-4910-579-14&P

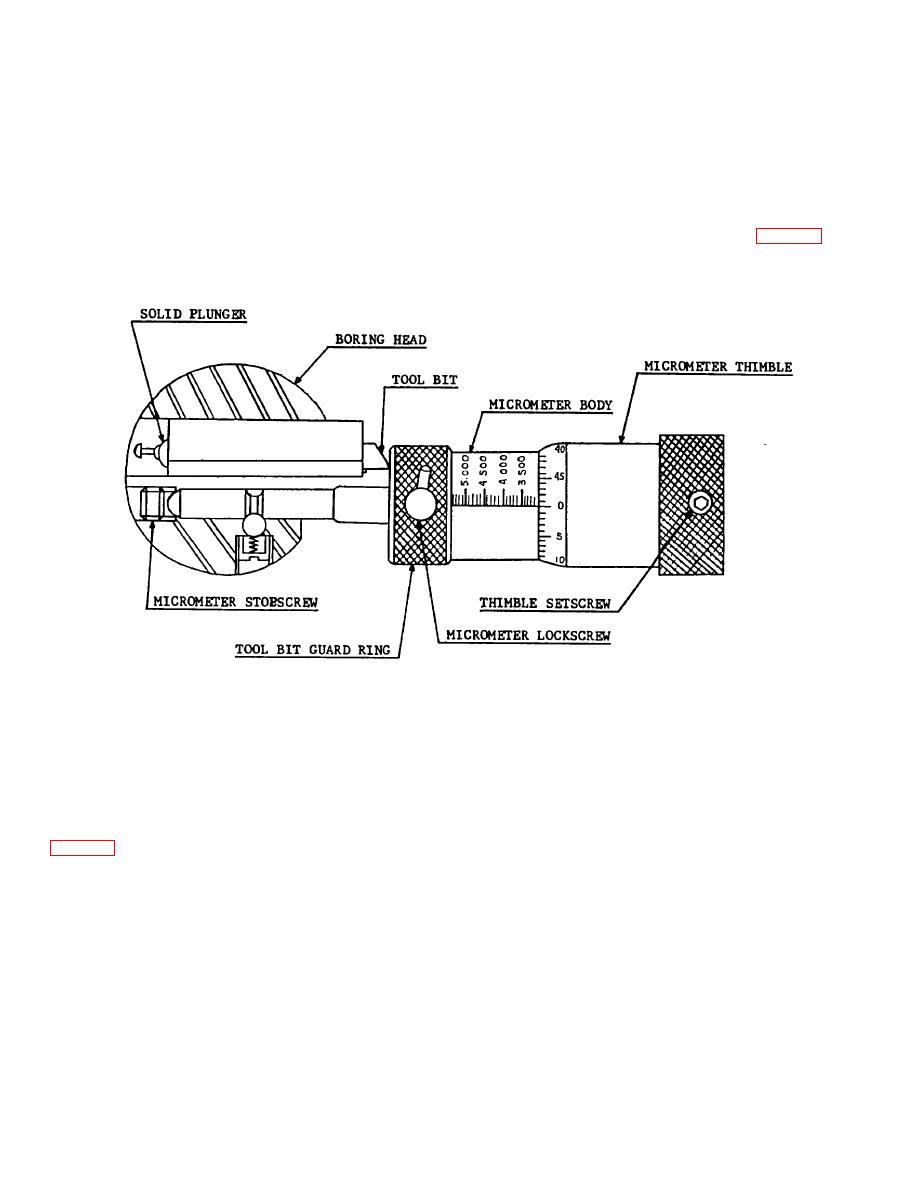

SETTING THE TOOL IN THE BORING HEAD

Determine the size to bore and set the micrometer. Each graduation of the micrometer body, or one revolution of the

thimble, represents fifty thousandths.

For the roughing cut, the micrometer should be set two thousandths smaller than the desired finished size. Two

thousandths is the proper amount for the finish cut. After setting the micrometer, lock it with the micrometer lockscrew.

Loosen the plunger lockscrew and place the R tool holder along side the micrometer spindle as shown in Figure 9. Move

the plunger until the overall length of the tool, tip of tool to tip of plunger, is approximately 1/2 inch longer than the

extended length of the micrometer stem.

FIGURE 9

SETTING THE TOOL IN THE BORING HEAD

CAUTION

UNLESS THE PLUNGER IS PROPERLY SET, IT WILL BE IMPOSSIBLE TO MAINTAIN

UNIFORMITY OF BORE SIZES.

Figure 9 shows the tool holder in the boring head ready to be locked in position. The small spring plunger is partly

compressed, thus pushing the tool holder .ad tool bit out against the face of the micrometer body with a light spring

pressure.

- 15 -