VACUUM CHAMBER DIAPHRAGM TEST.

ADVANCE TEST.

a. Insert the proper adapter in the primary

a. Adjust vacuum control until gage reads

vacuum chamber and tighten to insure a

zero, then disconnect hose,

good seal.

b. With distributor operating at minimum

rpm place degree ring zero in line with

b. Leave test leads connected and the lobe

one of the arrow flashes.

selector switch in the proper position as

c. Adjust vacuum and distributor speed for

before.

each specified check point in turn and note

c. Attach hose to vacuum unit and seal hose

the amount of advance obtained.

with metal clamp.

d. Reduce vacuum and distributor speed and

d. Adjust vacuum control until gage reads

again note advance obtained at each spec-

7 inches for 1953 models or 20 inches for

ified check point. Consult

later models.

service manual for specific adjusting pro-

e . Release hose clamp and observe gage.

cedures.

G a g e will momentarily fall to a lower

reading.

TRANSMISSION AND OVER-DRIVE GOVERNOR

( 1 ) If gage reading returns to original

TEST.

reading within a few seconds, vacu-

um chamber is air tight.

Test the transmission and overdrive governor as

(2) If gage reading fails to return to orig-

follows :

inal reading, chamber is leaky.

a. Place governor drive adapter in the dis-

tributor tester drive chuck and tighten.

BREAKER PLATE TEST.

b. Place governor in clamp and tighten se-

curely.

a. Adjust speed to 1000 rpm.

c. Adjust the elevating control so governor

b. With the vacuum control, increase vacu-

shaft fits into slot in drive adapter.

urn from 0 to 7 inches while watching

d. Connect distributor lead to contact ter-

dwell meter. If the dwell meter reading

minal on governor and ground lead to gov-

varies more than 2 degrees, wear in the

ernor body.

breaker plate bushing is indicated.

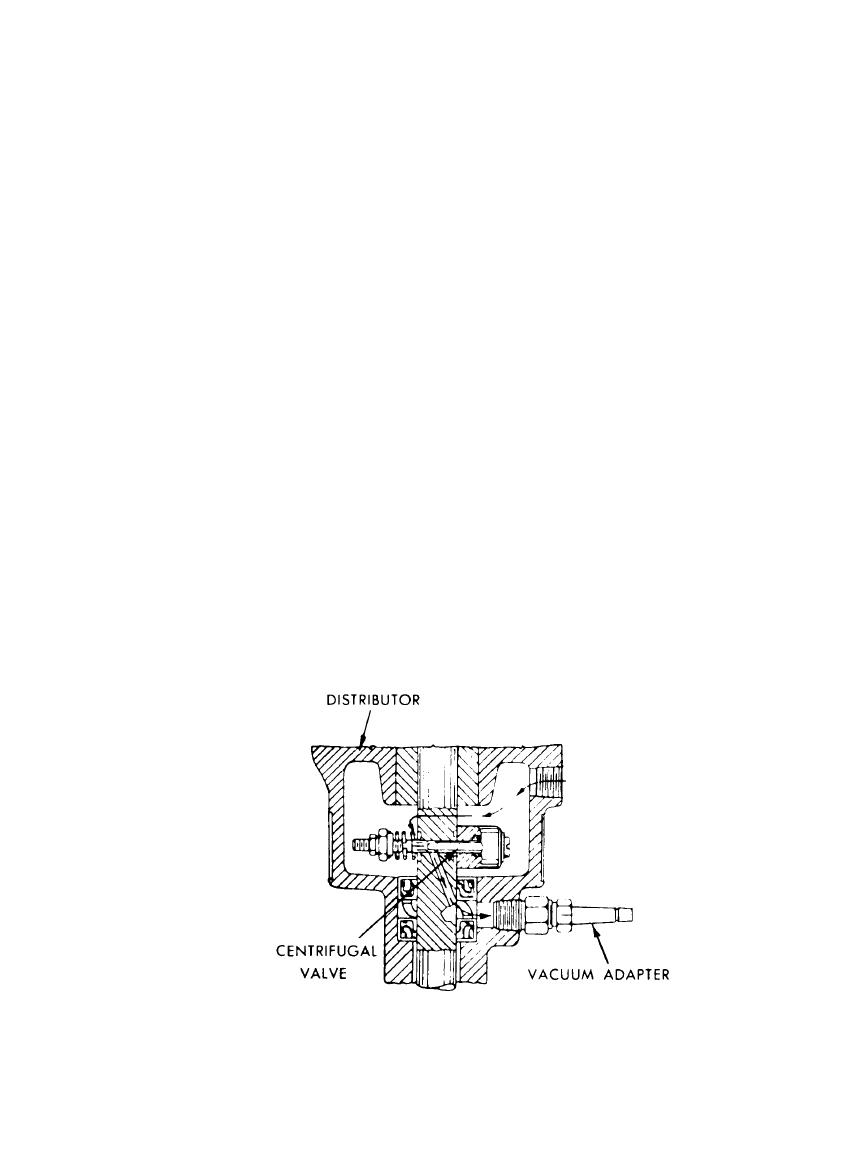

Delco-Remy Governor Cross-section