TM 9-4910-707-14&P

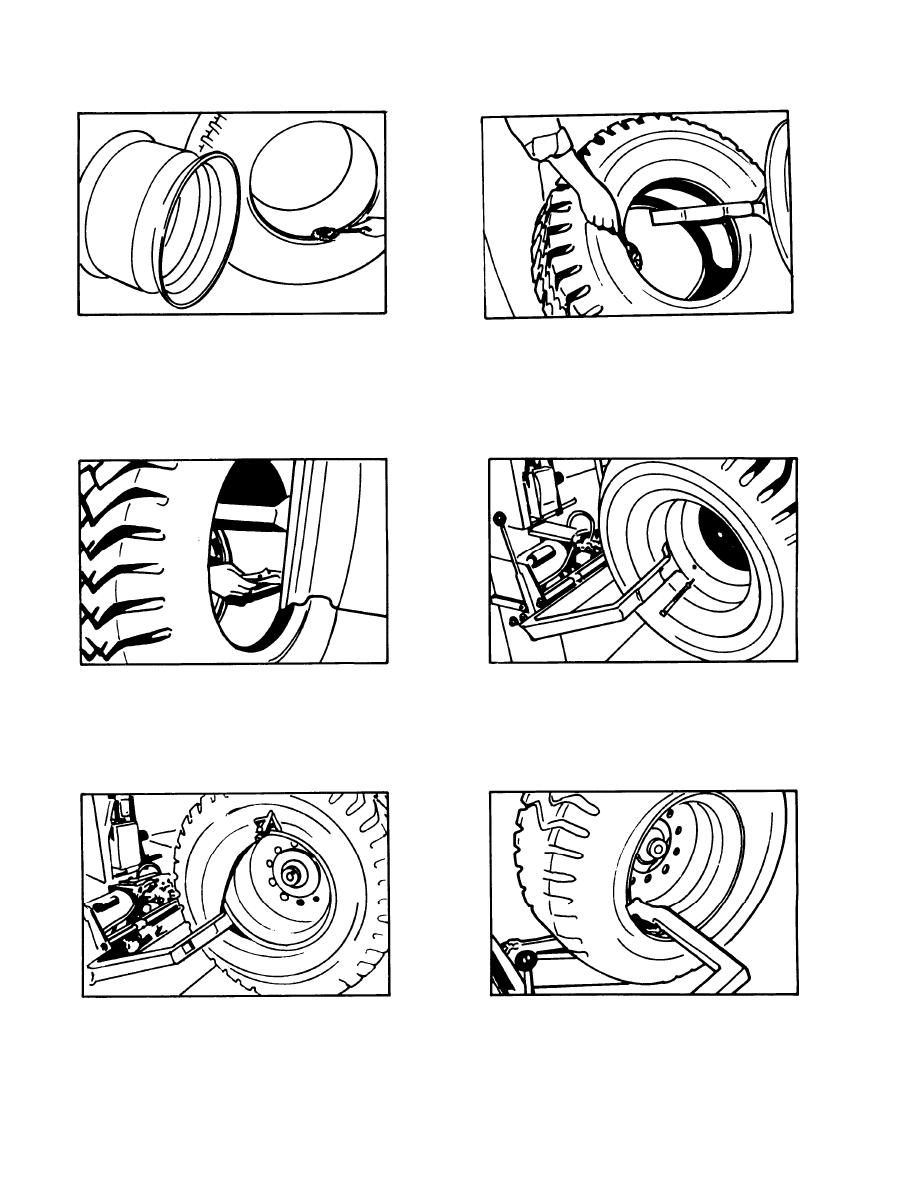

6. DUPLEX OR SUPER SINGLE ASSEMBLIES

.

B. With the tire located, position the duplex tool

A. Chuck the rim or wheel on the machine and

against the rim flange as shown above.

lubricate both beads thoroughly with NAS 1101-06-12.

D. Move the tire over, so the outer bead is near

C. Position the lower side of the first bead of

the outer rim flange. Clamp the mounting tool on

the tire near the area of the rim well. Clamp the

the rim flange as shown above.

mounting tool securely to the rim. Rotating the

tool in the normal manner, the mounting tool

should place the tire bead over the rim flange.

F. The photo above shows the tire mounted on

E. By rotating the wheel assembly, the mounting

the rim. Remove the bead mounting tool and posi-

tool should place the second bead over the rim

tion the duplex tool away from the tire and wheel

fIange.

assembly.

16