TM 3-1040-262-13&P

Table 3-1. Operator's Preventive Maintenance Checks and Services - Continued

B - Before Operation

A - After Operation

Interval

Procedures

For readiness reporting

Item

Check and have repaired or

equipment is not ready/

No.

B

A

Item to be inspected

adjusted as necessary

available if

OVERALL

pressure hose assembly (2), pressure reg-

VISUAL

ulator (4), and low pressure hose assembly

(Cont.)

(19) to make sure they are in serviceable

condition. Check the air cylinder and oth-

er hardware of the air pressure assembly

for loose connections. Check that the

high pressure rupture disk assembly (15,

pressure) (5) are not blown out. Inspect

the frame and harness assembly (fig. 1-2)

to make sure that the agent container

straps and the air cylinder strap fasten the

agent container and the air cylinder to the

frame. Make sure that the spring loaded

clamps are fully closed. Verify that

shoulder straps and waist strap are in ser-

viceable condition, free of excessive wear,

and that no slide buckles are missing or

broken. Inspect the frame for damage or

missing identification (fig. 1-6). Check

that screws and nuts securely fasten the

pressure regulator to the frame. If inspec-

tion reveals deficiencies in the frame and

harness assembly, notify organizational

maintenance personnel.

2

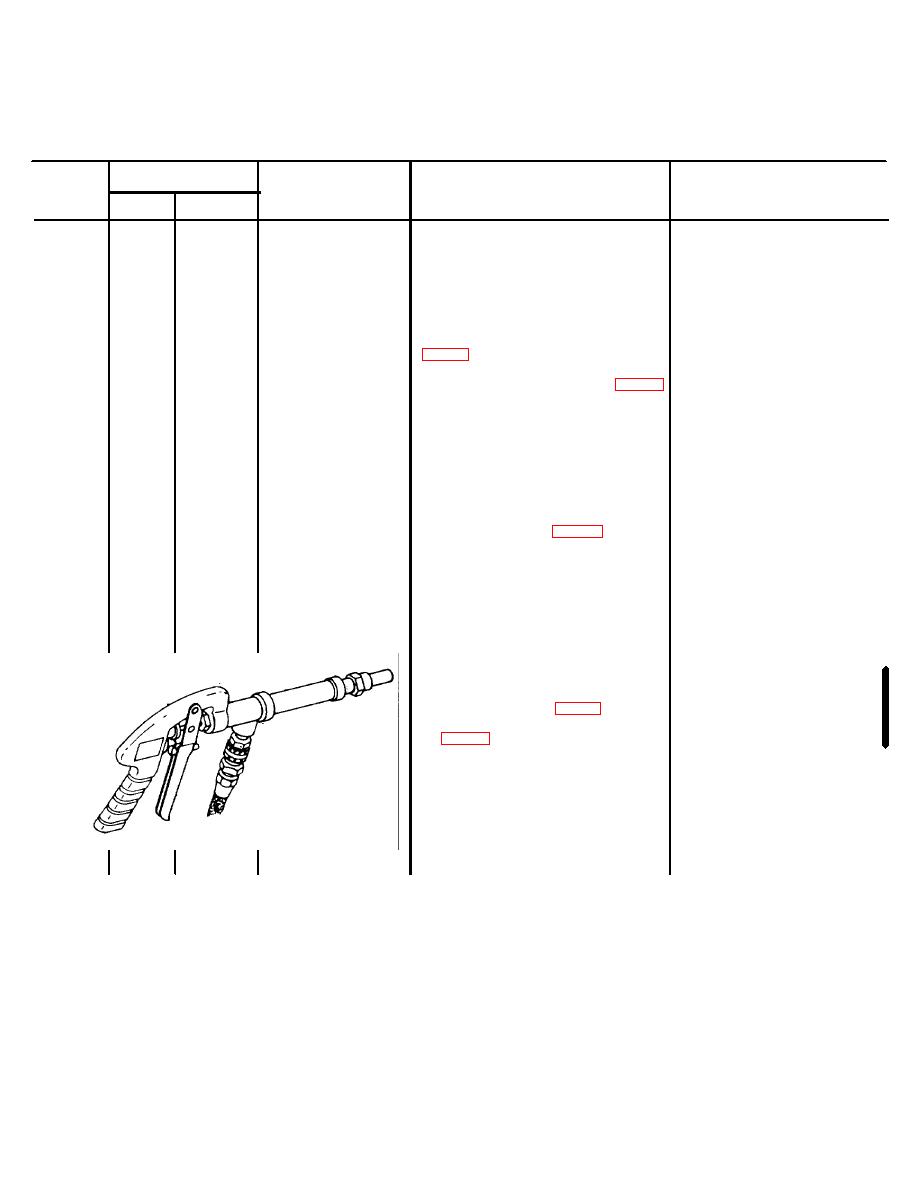

GUN ASSEMBLY

Inspect the disperser to determine that the

nozzle is installed. If the disperser is being

used with CS dry agent, the jet spray unit

must be installed on the gun. If the dis-

perser is being used with CR liquid agent,

the multijet spray unit (fig. 1-1) must be

installed on the gun. Turn the grip knob

(1, fig. 1-4) clockwise until resistance is

felt (approximately I full turn) to make

sure that the high-pressure air is shut off.

Make sure that hole in jet spray unit is not

plugged.

Change 1 3-3