TM 55-1925-286-13&P

0021 00

2

7

1

3

8

5

4

6

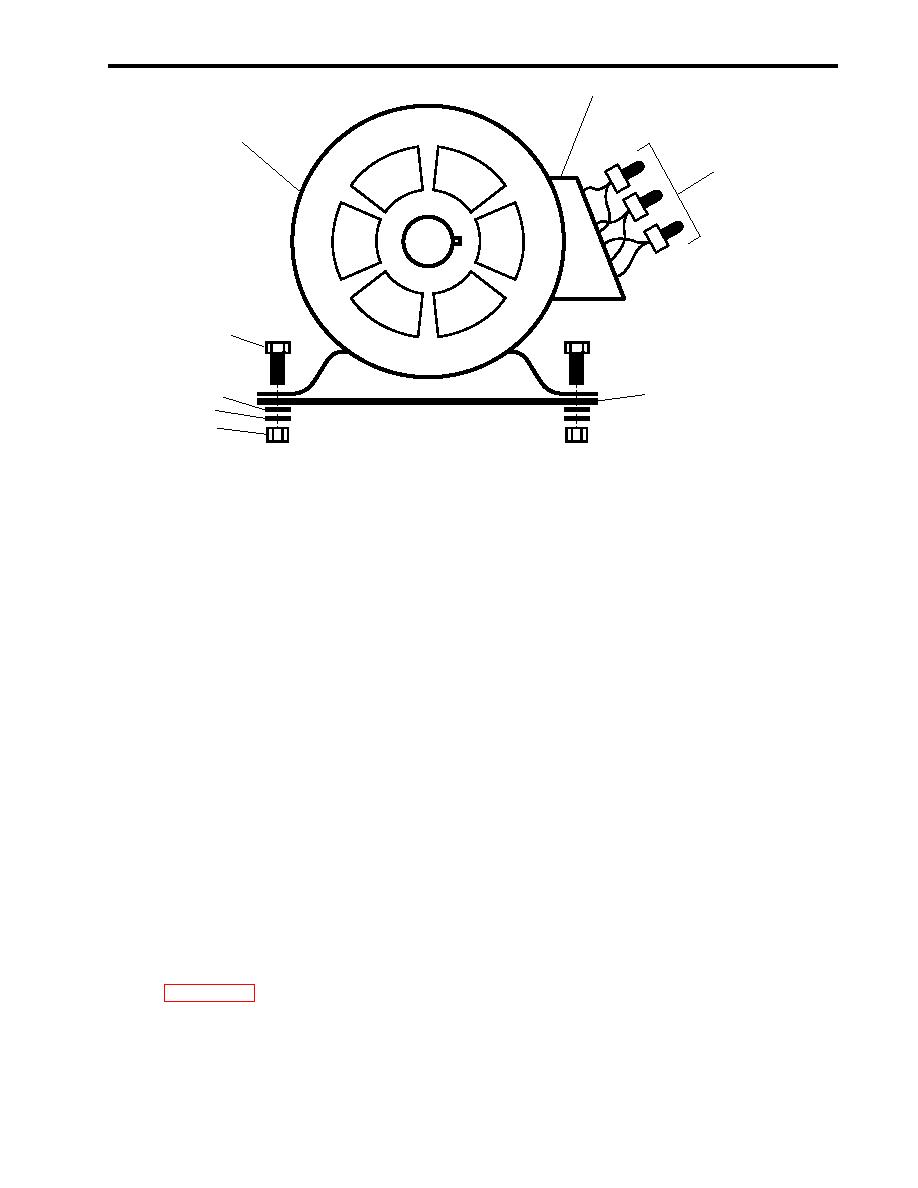

Figure 2. Junction Box

8. Remove the V belt (figure 1, item 8).

9. Remove the four bolts (figure 2, item 3), four washers (figure 2, item 4), four lockwashers (figure 2, item 5)

and four nuts (figure 2, item 6) that secure the motor (figure 2, item 7) to the foundation (figure 2, item 8).

Remove the motor from the foundation and discard the lockwashers.

INSTALLATION

1. Position the motor (figure 2, item 7) on the foundation (figure 2, item 8) and secure it loosely with the four

bolts (figure 2, item 3), four washers (figure 2, item 4), four new lockwashers (Figure 2, item 5), and four nuts

(figure 2, item 6). Do not tighten the bolts at this time.

2. Install the wiring (figure 2, item 1) into the junction box (figure 2, item 2) using the labels from step 5 of

Removal as a guide. Remove the labels.

3. Install the junction box cover (figure 1, item 2) and secure it with the four screws (figure 1, item 1).

4. Install the V belt (figure 1, item 8) and slide the motor (figure 1, item 3) away from the compressor (figure 1,

item 4) until the proper belt tension is achieved. Proper tension is achieved when the belt may be deflected

1/2 inch (13 mm) at its midpoint (figure 3) when applying approximatley 4 to 5 pounds (1.8 to 2.3 kg) of force

to the belt. A new belt should be tensioned tighter (approximately 3/8 inch (10 mm) deflection). Once proper

tension is achieved, tighten the four bolts (figure 2, item 3).

5. Install the belt guard (figure 1, item 7) and secure it with the three lower screws (figure 1, item 5) and one

upper screw (figure 1, item 6).

6. Remove the lockout and tagouts (FM 55-502) and return the air compressor to the normal operating condi-

tion (WP 0005 00).

7. Operate the air compressor and check for proprer operation.

8. Return the equipment to the desired readiness condition.

0021 00-3