TM 9-2330-211-14&P

2-4.

SPECIFIC PMCS PROCEDURES (Con't)

Leakage Definitions for Operator/Crew PMCS

Class I

Seepage of fluid (as indicated by wetness or discoloration) not

great enough to form drops.

Class II

Leakage of fluid great enough to form drops, but not great

enough to cause drops to drip from item being inspected.

Class III

Leakage of fluid great enough to form drops that fall from item

being inspected.

CAUTION

When operating with Class I or Class II leaks, continue to check fluid levels in

addition to that required in PMCS. Parts without fluid will stop working or may be

damaged.

Equipment operation is allowed with minor (Class I or II) leakage. Fluid levels in an item/system affected with such

leakage must be checked more frequently than required in PMCS. When in doubt, notify your supervisor.

Report Class III leaks IMMEDIATELY to your supervisor.

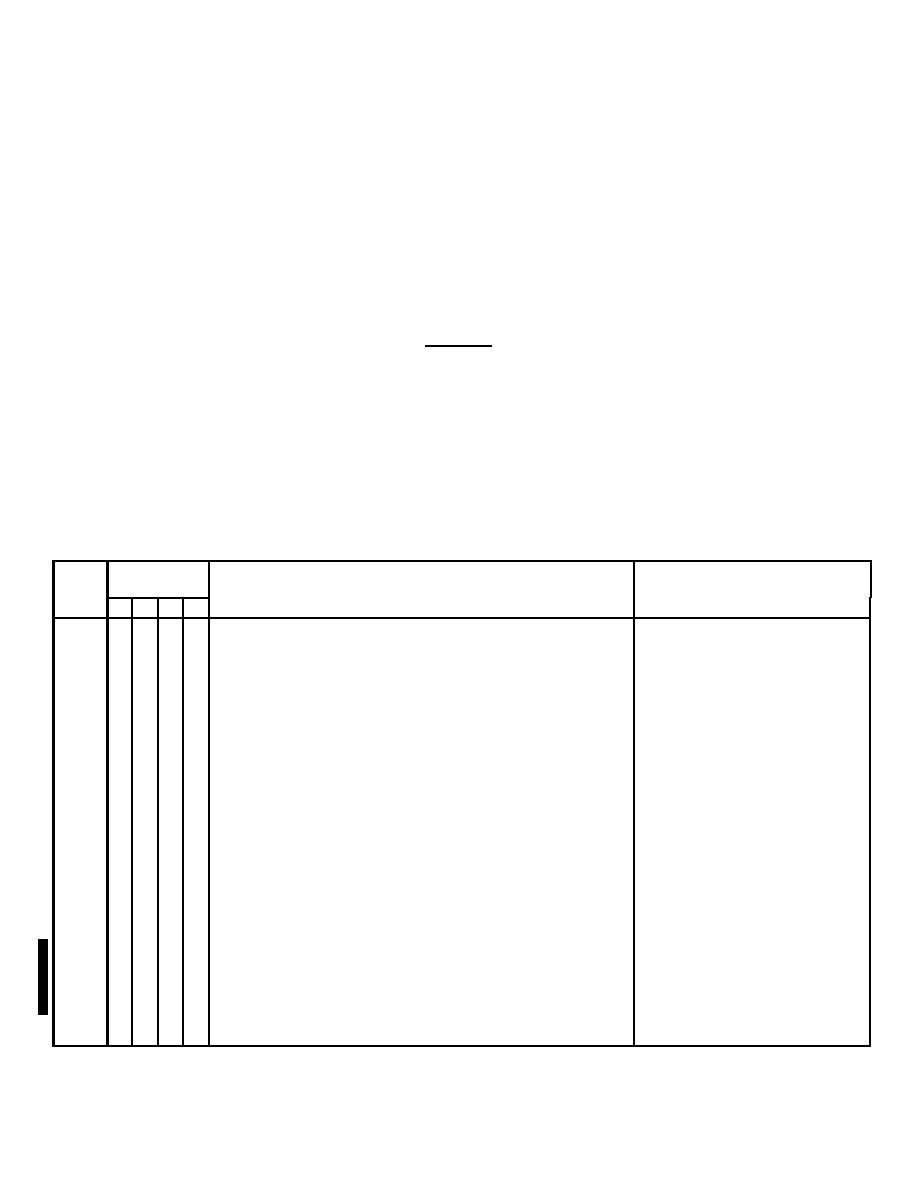

Table 2-1. Operator/Crew Preventive Maintenance Checks and Services (PMCS).

B - Before

D - During

A - After

W - Weekly

ITEM

INTERVAL

ITEM TO BE INSPECTED

EQUIPMENT IS NOT

NO.

PROCEDURE: CHECK FOR AND HAVE REPAIRED,

READY/AVAILABLE IF:

FILLED, OR ADJUSTED AS NEEDED

BDAW

NOTE

Perform (W) as well as (B) PMCS if:

You are the assigned operator but have

not used semitrailer since the last weekly.

You are using the semitrailer for the first

time.

MAKE THE FOLLOWING WALKAROUND CHECKS

1

BODY/ACCESSORIES

a.

Visually check for loose, missing, or damaged

parts.

b.

Check lights (1) and reflectors (2) for conditions and

Running, stop, or turn lights do

proper operation.

not operate.

2

FRAME

a.

Visually check for bent, cracked or broken frame.

Any broken frame.

b.

Visually check ramp outer rear clips for damage.

2-8 Change 2