TM 9-2330-211-14&P

Table 4-2. Unit Troubleshooting (Con't).

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

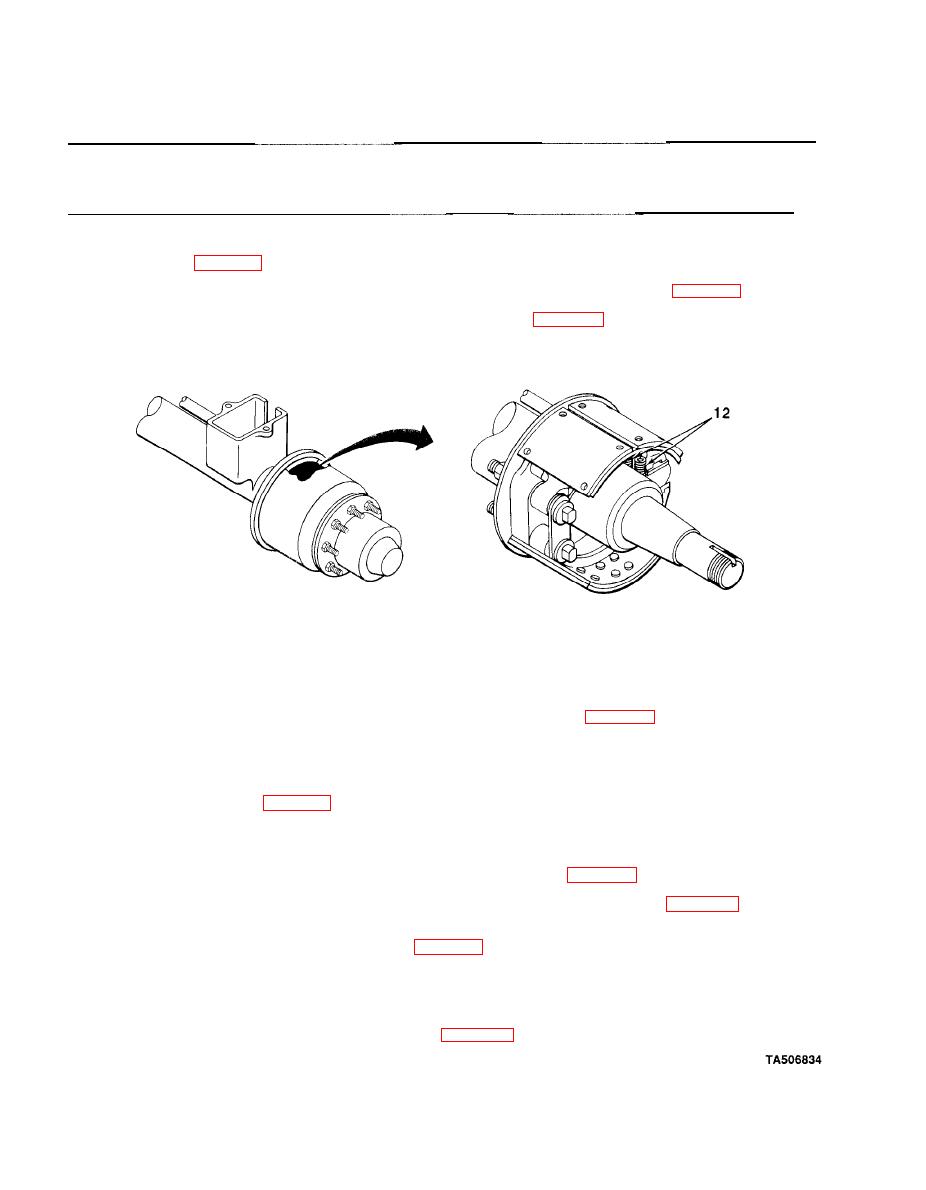

Remove wheel and drum, and check for distorted or broken brakeshoe return springs (12)

Step 4.

If return springs (12) are distorted or broken, replace return springs (para 4-21).

If brakes still will not release, check camshaft (para 4-24).

NO BRAKES OR WEAK BRAKES.

5.

Step 1.

Check for restricted and leaking service air line (14).

If service air line (14) is restricted or damaged, repair (para 4-28).

Disconnect service air line (14) at emergency relay valve (13). Apply and release service brakes.

Step 2.

Air should escape when brakes are applied, and stop when brakes are released.

If airflow does not react as stated above, service air line (14) is clogged. Repair service air

line (para 4-28).

Visually inspect air line (16) between air reservoir (15) and emergency relay valve (13) for dents,

Step 3.

cracks, and breaks.

If air line (16) is dented, cracked, or broken, repair (para 4-28).

Cautiously loosen air reservoir fitting (17) at emergency relay valve (13) (para 4-28). Air should

Step 4.

escape; no air means a clogged air line.

If air line is clogged, repair (para 4-28).

Cautiously loosen air line fitting (19) at emergency relay valve (13) that supplies air to airbrake

Step 5.

chambers (10). Have assistant apply brakes and note airflow to airbrake chambers.

If there is no airflow to airbrake chambers (10), emergency relay valve (13) is defective.

Replace emergency relay valve (para 4-31).

4-14