TM 9-2330-271-14&P

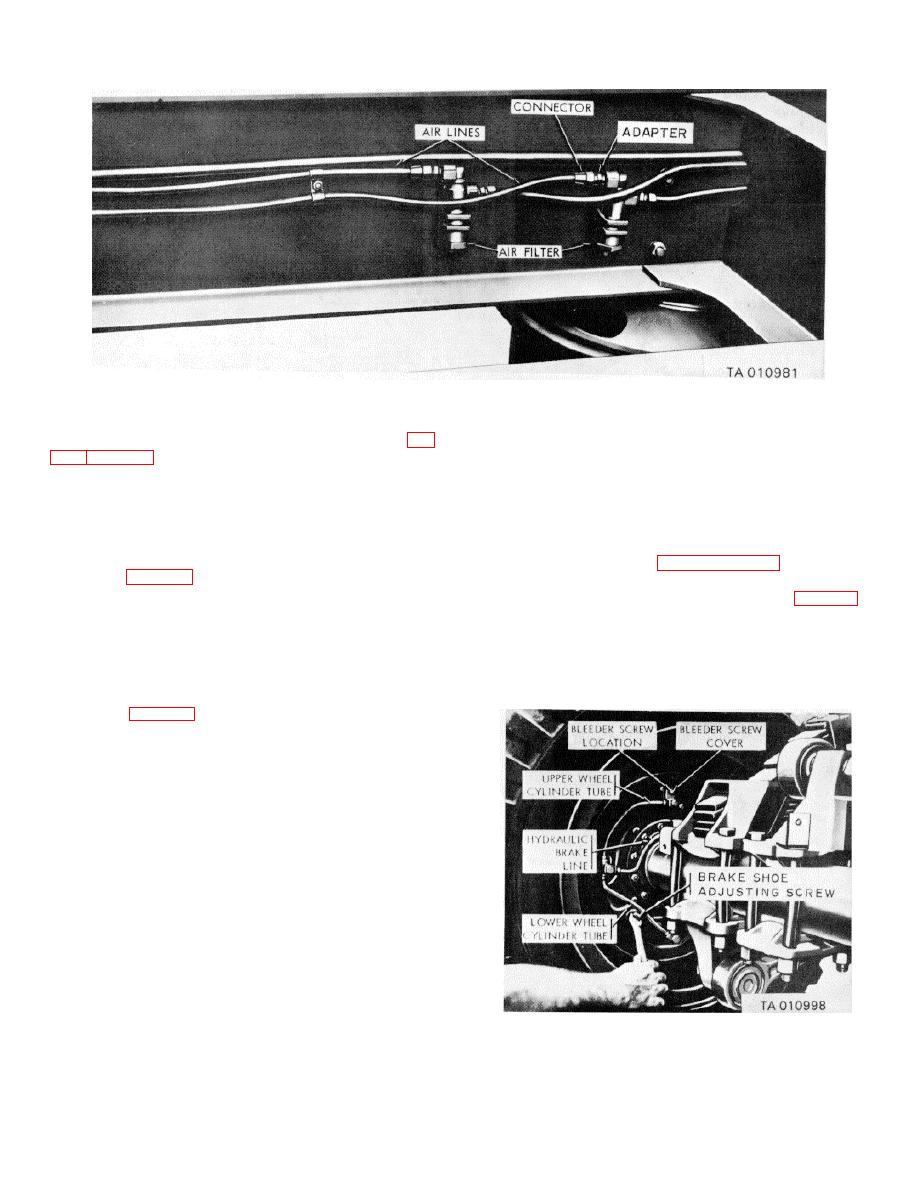

Figure 4-25. Air lines and air filters (some models).

k. Emergency Air Line. The emergency air line (fig.

(2) Place jack under axle and raise rear of

semitrailer until tires clear ground.

b. Adjustment

EMERGENCY) along the inside of the left side rail,

through an air filter (on some models) and into the

NOTE

bottom of the relay valve assembly It transmits

Try to laterally rock wheel, hub and

compressed air to fill the air reservoir and to maintain the

brake drum assembly on axle spindle

proper air pressure under the control of the relay valve.

If rocking condition prevails, adjust

I.

Air Filters Some model semitrailers incorporate

wheel bearings (paragraph 4-47f(6))

air filters (fig. 4-25) connected into the air lines at the

before making brake adjustment.

midpoint of the chassis frame to prevent moisture or

(1) Turn brake shoe adjusting screw (fig 4-26),

foreign matter from passing through the air lines

located at top rear face of brake backing plate, clockwise

Removable elements, held in place by spring washers

to expand the front brake lining in contact with brake

and compression springs, are removed by unscrewing a

drum until brakes drag slightly when wheel or drum is

cap nut. A square head pipe plug in the cap nut is

turned by hand.

removed to drain any moisture.

(2) Back off adjusting screw just enough to

m. Wheel Brake Mechanism. Each wheel brake

allow drum to rotate freely.

mechanism (fig. 4-24), located within the brake drum and

supported by a brake backing plate, has two brake shoes

fitted with brake linings. Two hydraulic cylinders are

mounted between the ends of the shoes. Slotted piston

rods in each end of the cylinder engage with slots in the

end of each brake shoe. Hydraulic pressure forces the

cylinder piston outward to apply the brake linings to the

drum Two brake retracting springs draw the shoes away

from the drums when hydraulic pressure is not applied

and hold it in the retracted or released position.

4-32.

Brake Adjustment

a.

Preliminary Steps.

(1) Release pressure from braking system by

opening drain cock on air reservoir.

Figure 4-26. Brake adjustment.

4-40