TM 9-2330-294-14

(1) Reassemble each equalizer beam assembly

c. Cleaning. Clean all dirt and grease from

to axle in reverse order of removal (b (16), (17), and

suspension parts using dry-cleaning solvent type II

(18) above). Using torque Wrench (GGG-W-686)

(SD-2) and a stiff fiber brush.

torque beam-to-axle shaft nuts to 1,260-1,680 lb ft.

d. Inspection.

CAUTION

(1) Inspect parts for cracks, damage or wear.

Take care not to damage or fold over lips of

(2) Inspect torque rod rubber bushing for

grease seal when inserting equalizer beam

damage or deterioration.

center shaft.

(3) Inspect felt washers on beam-to-axle shaft

(2) Insert equalizer beam center shaft in center

for wear.

(4) Inspect axle shaft for fatique cracks around

housing of each equalizer beam.

bearing journals, shoulders and welded hanger

(3) Install remaining axle components in

reverse order of disassembly (b (9) through (14)

brackets or tapping pads.

above.

(5) Inspect journals for extreme wear or

scoring. No more than 10 percent of bearing surfaces

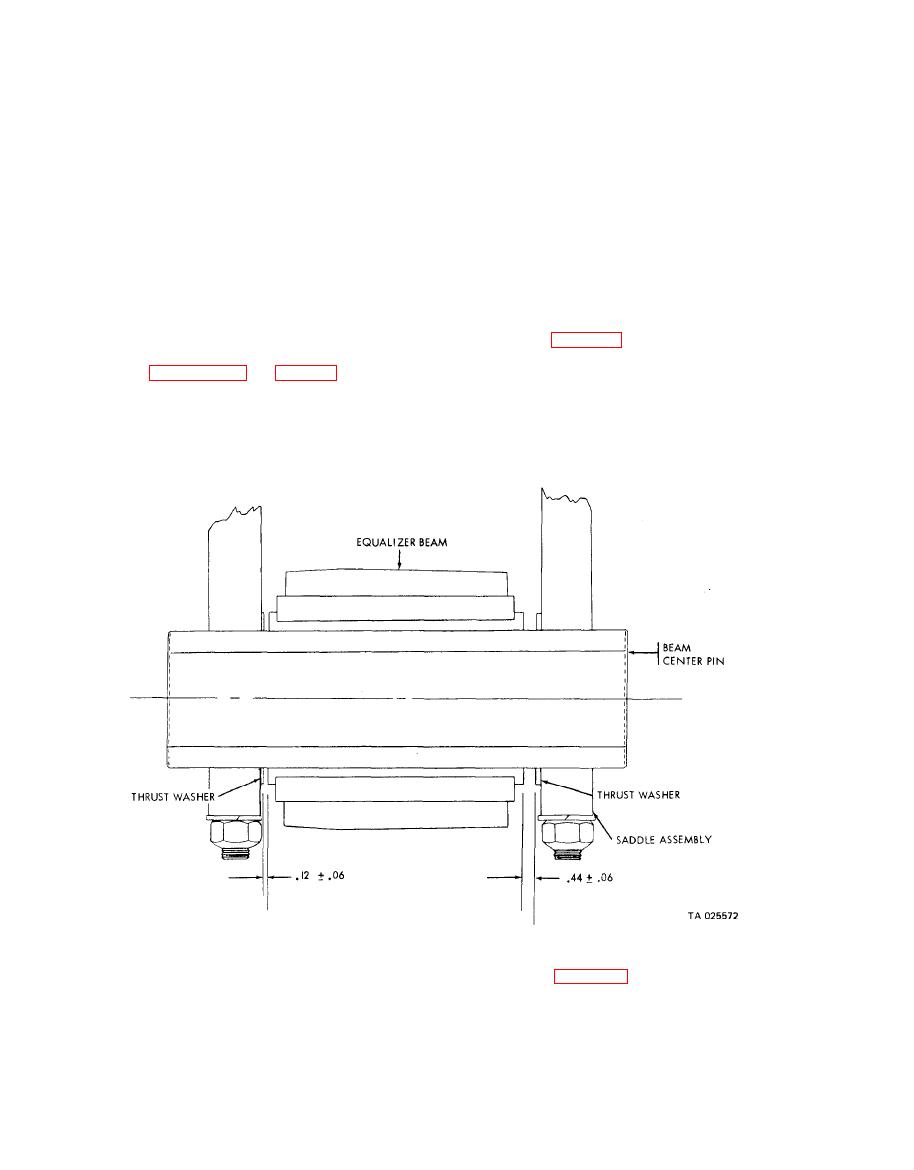

(4) With chassis raised, position front bogie

can be pitted or scored. Markings cannot be over

in place. Refer to figure 5-6 and aline bogie laterally

so that 0.44 inch gap exists on the inward side of

0.002 inches deep.

(6) See paragraph 6-6 and table 6-1 for repair

either beam. Use as many thrust washers as

standards for axle and equalizer beam.

required on the center pin to achieve this dimen-

e. Repair.

sion. This gap allows lateral travel along the beam

(1) Replace parts damaged or excessively worn.

center pin during certain suspension stress con-

(2) Replace axle member of damage is found.

ditions.

f. Installation.

(6) Refer to figure 5-5 and install each torque

(5) Secure left equalizer beam to saddle

rod on axle bracket with locking adapters through

assembly with four nuts and flat washers and

torque rod bracket leg holes and into torque rod end

tighten to 480 - 640 lb ft torque. Secure right

holes.

equalizer beam by same procedure.