TM 9-2330-294-14

6-33. Assembly

CAUTION

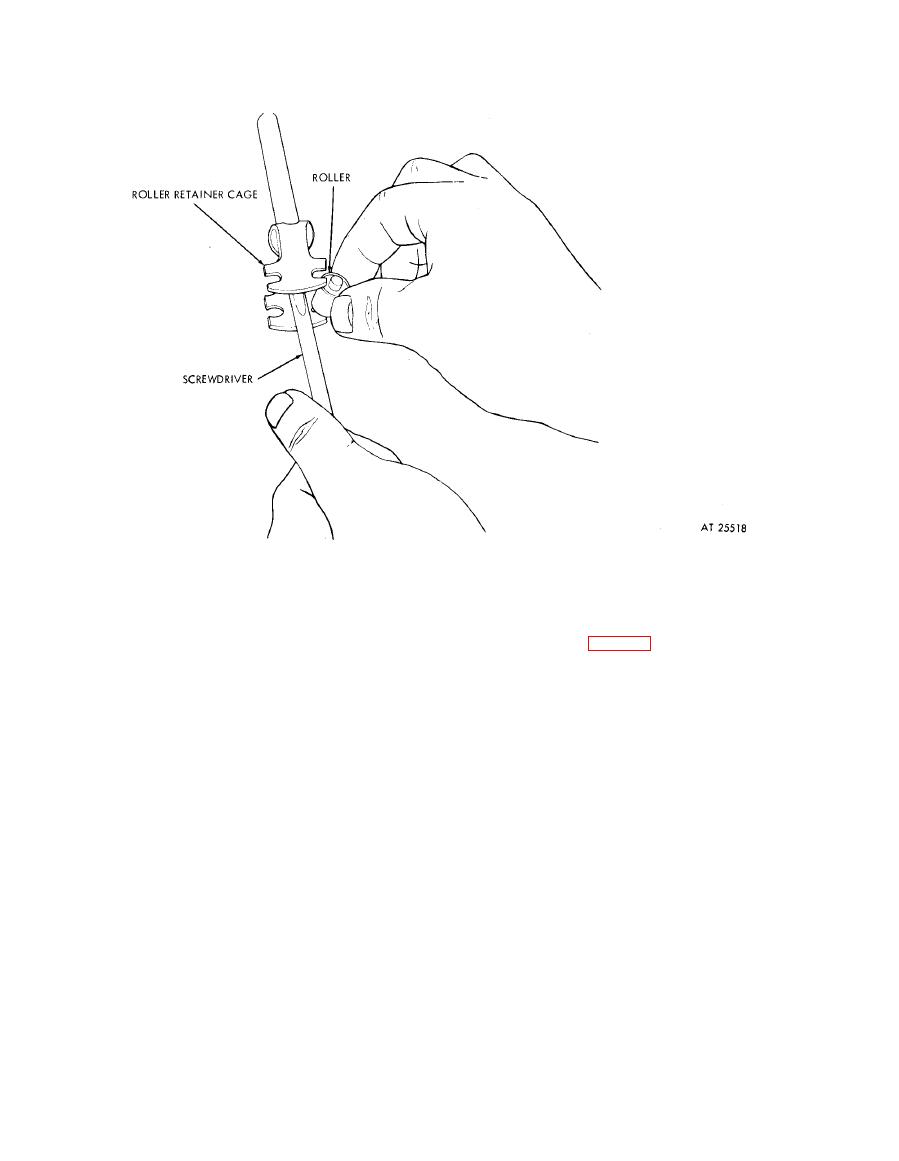

Do not attempt to drive the wedge through

a. Insert wedge shaft into roller retainer cage so

the rollers and cage or force the rollers

angled faces of the wedge head are exposed.

through the slightly closed slots of the cage.

This will damage the cage.

wedge head and roller retainer cage. Spread cage

open just enough to insert roller journal hub into

cage slot. Tip roller into cage and position other

a. Cleaning. Clean all metal parts using dry

journal hub into slot of retainer cage. Install other

cleaning solvent type II (SD-2).

roller in same manner and remove screwdriver. Do

b. Inspection.

not force rollers through end of the cage slots.

(1) Inspect angled faces of wedge for nicks, pits

c. Install spring retaining washer over wedge

or grooves.

shaft and position centrally over cage and roller

(2) Inspect spring for cracks.

assembly. Install rubber boot.

(3) Inspect roller cage to ensure proper holding

d. Install wedge spring over wedge shaft. Add

of rollers.

spring washer and compress spring by hand far

c. Repair. Replace damaged or defective parts.

enough to expose cotter pin hole. Insert cotter pin,

Replace boot.

Section X. HUB AND DRUM REPAIR

assembly of the hub and drum. Repair of the hub and

6-34. General

drum consists of replacing damaged studs and minor

This section provides information to direct and

refacing of the drum. This section also covers wear

general support maintenance personnel for the

limit standards for wheel bearings.

disassembly, cleaning, inspection, repair and