TM 9-2330-294-14

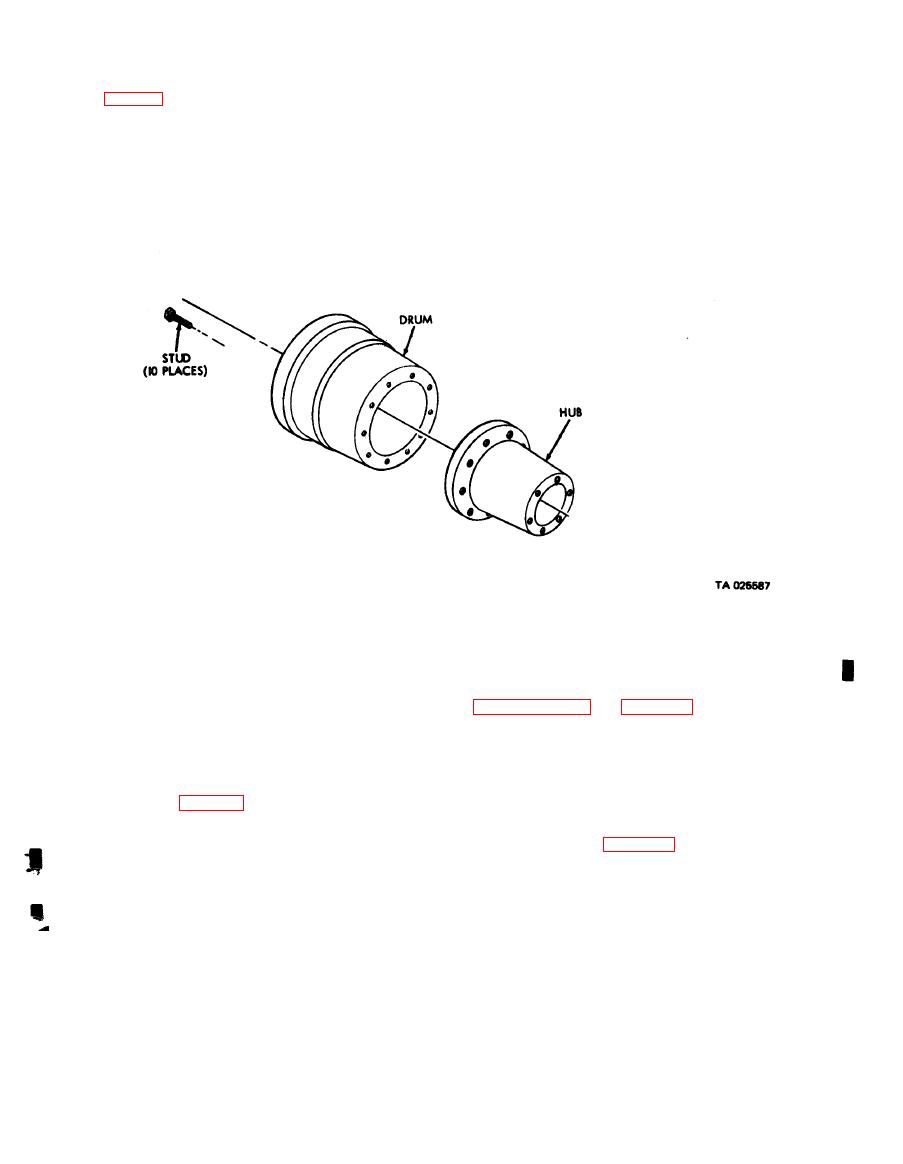

be reinstalled in the same holes. Mark relative

6-35. Disassembly

position of drum to hub.

b. Separte hub from drum by pressing ten studs

a. Position hub and drum on hub end. Use

out with arbor press.

suitable marker and number each wheel stud head

and adjust area of drum or hub so that studs can

inches, and should not be machined to a size

greater than 15.090 inches.

a. Cleaning. Clean hub and drum using dry

(2) Replace parts worn beyond limits specified

cleaning solvent type II (SD-2).

m paragraph 6-37 and table 6-3.

b. Inspection.

(3) When a damaged or broken wheel stud is

(1) Inspect inside of drum for pitting or scoring.

replaced, the stud on each side of it should be

(2) Inspect hub bearing surfaces for critical

replaced. This is necessary because the studs near

damage

the damaged or broken stud halve been carrying a

(3) Inspect hub and bearings for conformity to

heavier than normal load and may be weakened.

repair standards (table 6-3).

(4) Inspect wheel studs for damage.

(5) Inspect drum for out-of-round condition.

The repair standards (table 6-3) give the minimum,

(6) Inspect inside of drum for deep cracks.

maximum and critical clearance of new or rebuilt

This condition is tolerable only to 0.020 inch.

parts. They also give wear limits which indicate the

c. Repair.

p o i n t to which a part(s) may be worn before

(1) Drums that are scored, pitted or have deep

replacement. An asterisk (*)in the wear limits

cracks on the inner surface can be machined in

column indicates that the part(s) should be replaced

10 inch increments.

However, the refacing

when worn beyond the limits given in the sise and fit

he minor, since oversize brake linings are not

of new parts column. The letter (L) indicates loose

available. The inside diameter of a new drum is 15

fit. The letter (T) indicates tight fit.

Change 2