TM 9-2330-357-14&P

Table 4-2. Organizational Troubleshooting (Con't).

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

Step 3.

Disconnect cable at outrigger actuator and check for 24 V dc to ground at pin F.

Check wiring harness if 24 V dc is not present (see FO-1).

Step 4.

Check pins E and F on outrigger actuator connector for less than 1 ohm resistance.

Replace outrigger drive motor if more than 1 ohm resistance (para 4-50).

Step 5.

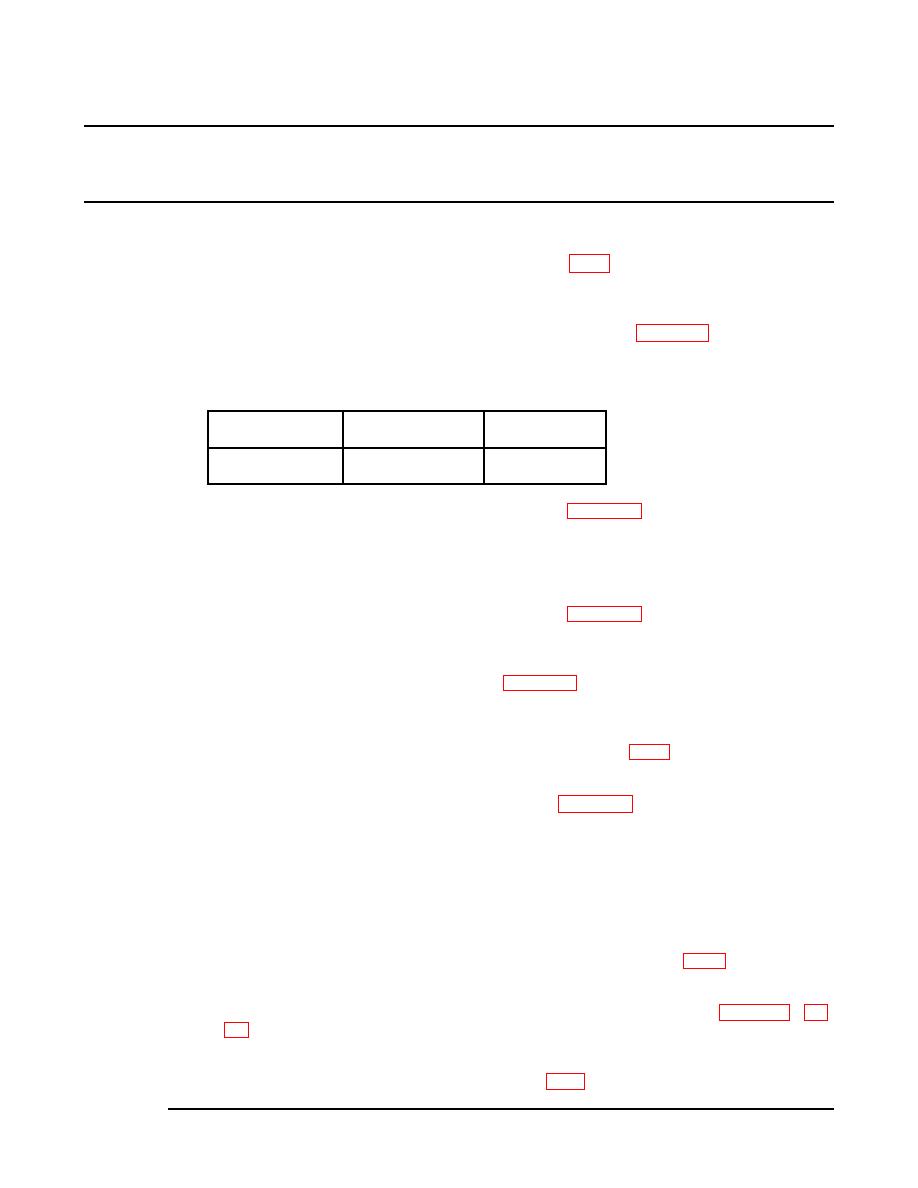

Jumper pins E and F on cable. Have another person hold outrigger switch first in up

position, then in down position. Check for following indications:

Pins A and D

Pins B and C

Pins G and H

24 V dc

24 V dc

24 V dc

Replace outrigger drive motor if voltage is present (para 4-50).

Replace relay panel if voltage is not present.

Step 6.

Check for defective outrigger control panel switches.

Replace defective outrigger control panel switches (para 4-22).

Step 7.

Check for defective outrigger drive motors.

Replace defective outrigger drive motors (para 4-50).

Step 8.

Check for defective or damaged wiring harness.

Replace or repair defective or damaged wiring harness (see FO-1).

Step 9.

Check for defective or damaged outrigger actuator.

Replace defective or damaged outrigger actuator (para 4-48).

14. OUTRIGGER INTERLOCK SYSTEM INOPERATIVE.

Step 1.

With all outriggers positioned 50 or greater below horizontal of semitrailer bed, test for

continuity at interlock harness receptacle. Test should show a "closed" circuit between contacts

A and B. Any one outrigger, when raised to less than 50 below horizontal will "open" interlock

circuit.

Replace interlock harness receptacle if continuity is not present (see FO-1).

Step 2.

Test individual upper and lower outrigger limit switches for continuity.

Replace upper or lower outrigger limit switches if continuity is not present (para 4-24 or 4-

Step 3.

Check interlock wiring harness for frayed, cracked, or broken condition.

Replace defective interlock wiring harness (see FO-1).

4-17