TM 9-2330-357-14&P

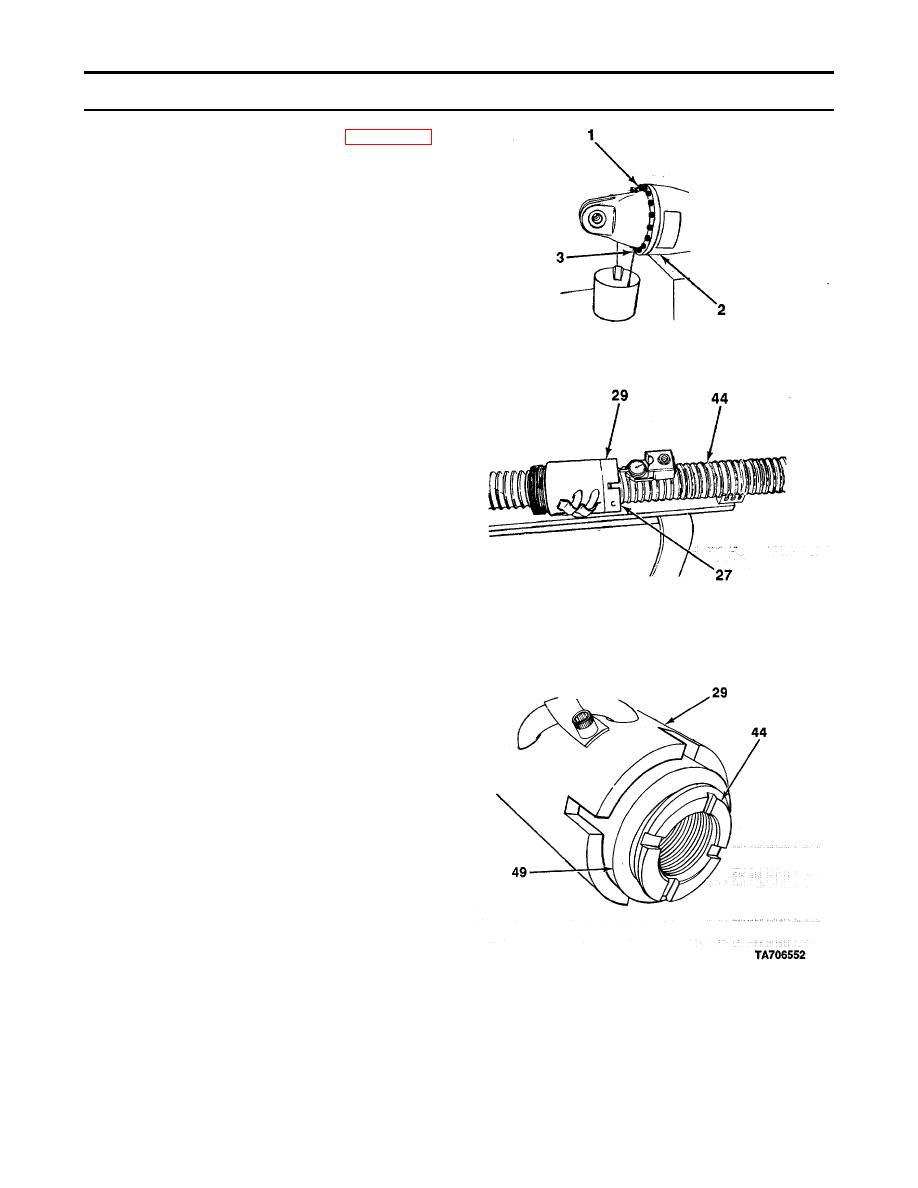

5-11. OUTRIGGER ACTUATOR ASSEMBLY REPAIR (Con't).

37.

Apply sealing compound (Item 6, Appendix E)

to threads in upper drain plug (1) and lower

drain plug (3).

38.

Install lower drain plug (3) into outrigger

actuator assembly (2).

39.

Install outrigger actuator assembly (2) in

horizontal jig with lower drain plug (3) down

and fill gear housing with two quarts of

hydraulic fluid. Install upper drain plug (1).

40.

Install ball screw subassembly (27) in v-blocks

on surface plate and clamp both ends to v-

blocks and table.

41.

Install C-clamp on ball nut (29) with C-clamp

handle resting on edge of surface plate to keep

ball nut from rotating on ball screw (44).

42.

Install magnetic base indicator on ball screw

(44) with stylus on end face of ball nut (,29).

NOTE

If backlash is more than 0.013 In. (0.33 mm), ball screw subassembly must be replaced.

43.

Push and pull on ball nut (29) to read magnetic

base indicator. Repeat procedure at three

equally spaced positions. Backlash should not

be more than 0.013 in. (0.33 mm).

44.

Install ball screw subassembly (27) in vertical

jig and thread new seal (49) onto ball screw

(44) with larger outside diameter surface

outward.

45.

Hold seal (49) and rotate ball nut (29) counter-

clockwise over seal until outward face of seal

is flush with bottom of slots in ball nut.

5-46