TM 9-2330-376-14&P

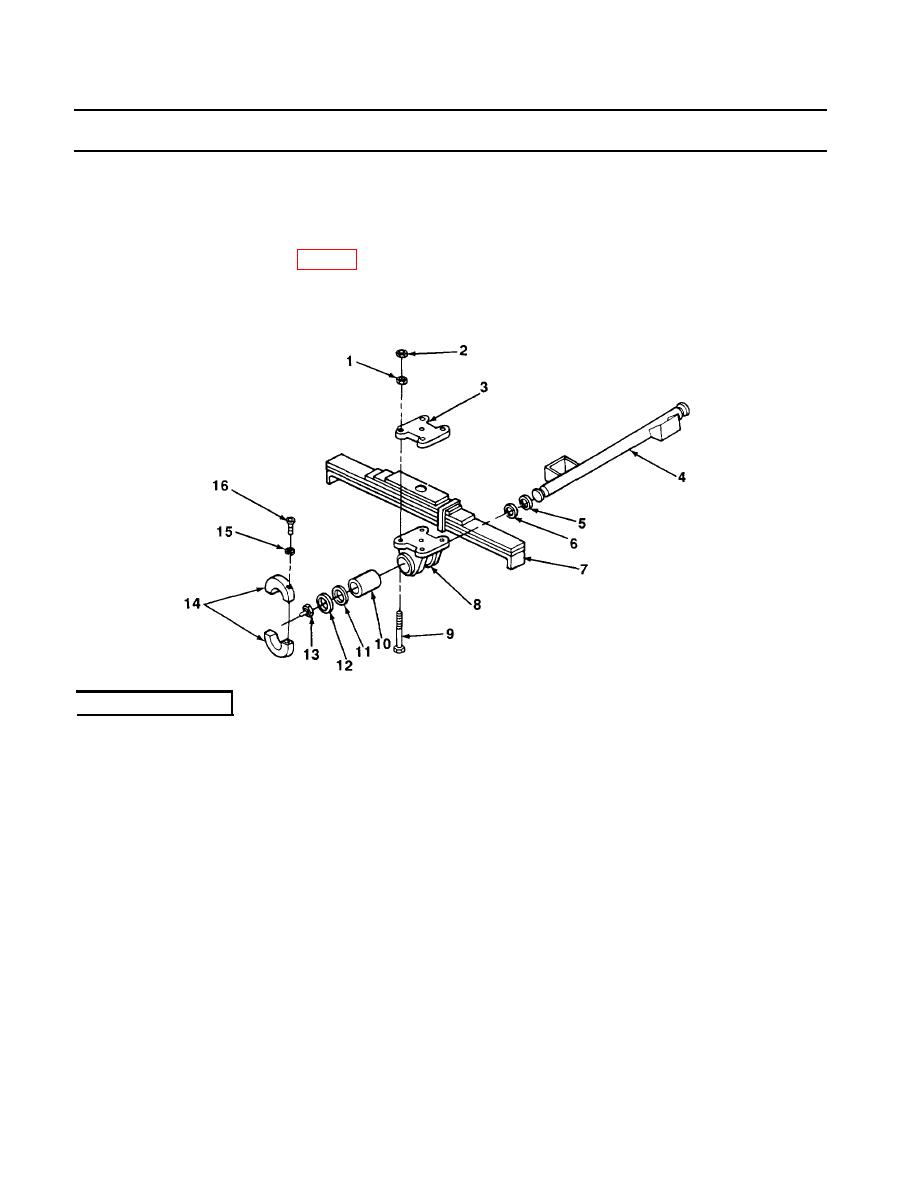

5 - 3 . TRUNNION AXLE REPLACEMENT (Con't).

If damaged, remove lubrication fitting (13) from trunnion axle (4) and discard.

5.

Remove flatwasher (12) and thrust bearing washer (11) from trunnion axle (4).

6.

7.

Remove bracket assembly (8).

Inspect sleeve bearing (10)(para4-18), If scored, worn, or deformed, remove from bracket assembly (8) using a

8.

suitable puller. Discard sleeve bearing.

Remove thrust bearing washer (6) and flatwasher (5) from trunnion axle (4).

9.

b.

INSTALLATION

NOTE

Perform steps 1 through 8 at each end of trunnlon axle.

1.

Install flatwasher (5) and thrust bearing washer (6) on trunnion axle (4).

If removed, use a block of wood and hammer to install new sleeve bearing (10) in bracket assembly (8).

2.

Apply a thin coat of grease to sleeve bearing (10). Install bracket assembly (8) on trunnion axle (4).

3.

Install thrust bearing washer (11) and flatwasher (12) on trunnion axle (4).

4.

If removed, install new lubrication fitting (13) in trunnion axle (4).

5.

Install two Iockrings (14) with socket head screws (16) and new Iockwashers (15).

6.

Raise trunnion axle (4) into place under spring assemblies (7) and support.

7.

Install spacer plate (3) with four screws (9) and nuts (l). Torque nuts to 150-175 Ib.-ft. (203-237 Nm). Install four

8.

jamnuts (2).

Remove floor jack from under trunnion axle (4)

9.

TA701016

5-10