TM 9-2330-381-14

4-41. SUSPENSION CYLINDER (CONT)

14.

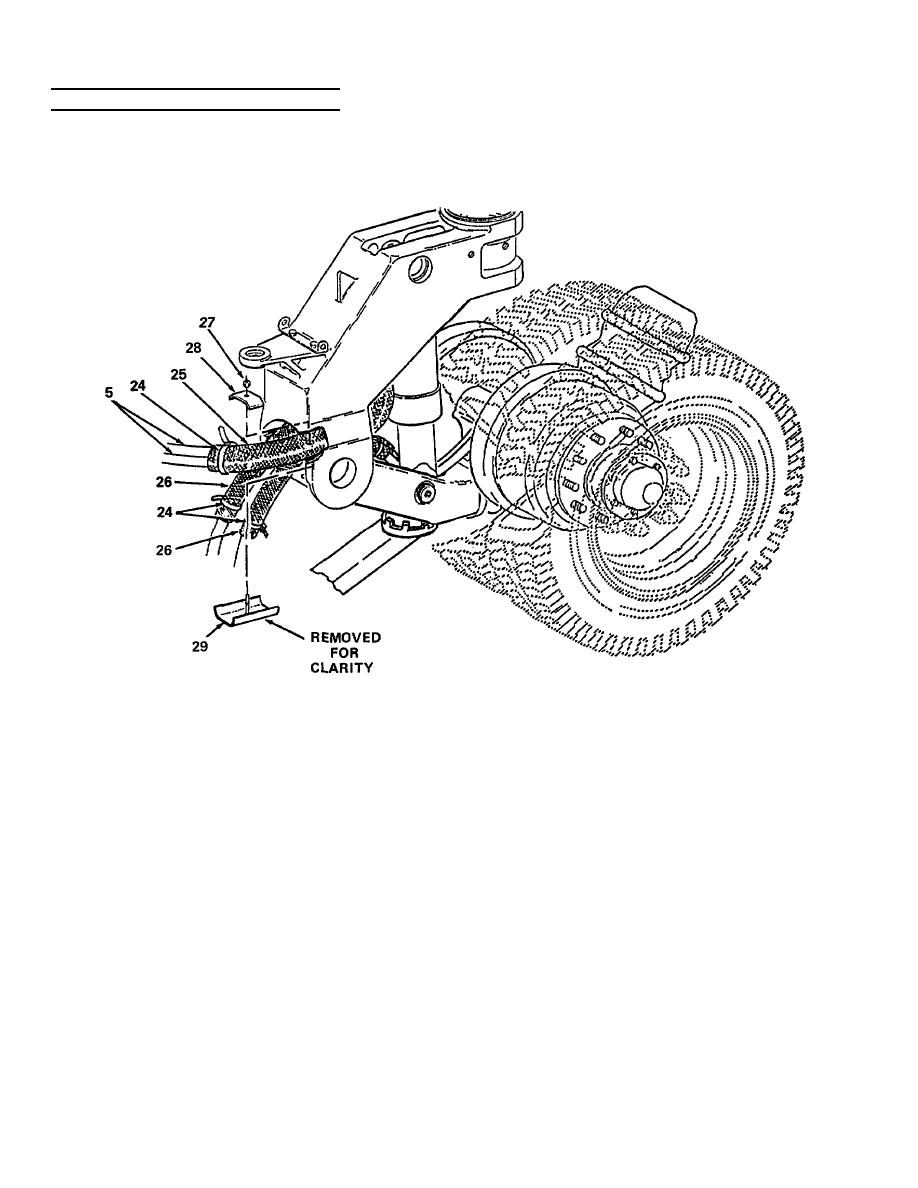

Mark locations of all electrical tiedown straps (24) and mark starting and ending points for each protective loom

(25 and 26) on each hose with chalk. Cut and remove all accessible electrical tiedown straps (24).

15.

Remove locknut (27), loop clamp (28) from skid assembly (29) and two hydraulic hoses (5). Discard locknut.

16.

Using external retaining ring pliers, remove two retaining rings (30) from upper pin (31). Remove lubrication fitting

(32) from upper pin (31).

17.

Using sledge hammer and removal tool, drive upper pin (31) out of upper suspension arm (17) and suspension

cylinder (6).

NOTE

As the suspension cylinder is lowered out of the upper suspension arm, ring

spacer assemblies will probably fall to the ground.

18.

Once upper pin (31) has been removed, lower hydraulic floor jack (1), compress suspension cylinder (6) fully and

then pull on suspension cylinder (6) so that cylinder rests back against axle (33).

4-178