TM 9-2330-381-14

3.

Install s-cam retainer assembly (4) onto axle (5) and install four capscrews (3), eight flat washers (2), and four

nuts (1). Using a torque wrench, torque nuts (1) to 30 - 40 lb-ft (41 - 54 Nm).

FOLLOW-ON MAINTENANCE

Install left-hand and right-hand s-cam and slack adjusters (para. 4-44).

4-46.

SLACK ADJUSTER

This task covers inspection.

INITIAL SETUP

Equipment Condition

S-cam for defective slack adjuster removed (para. 4-44)

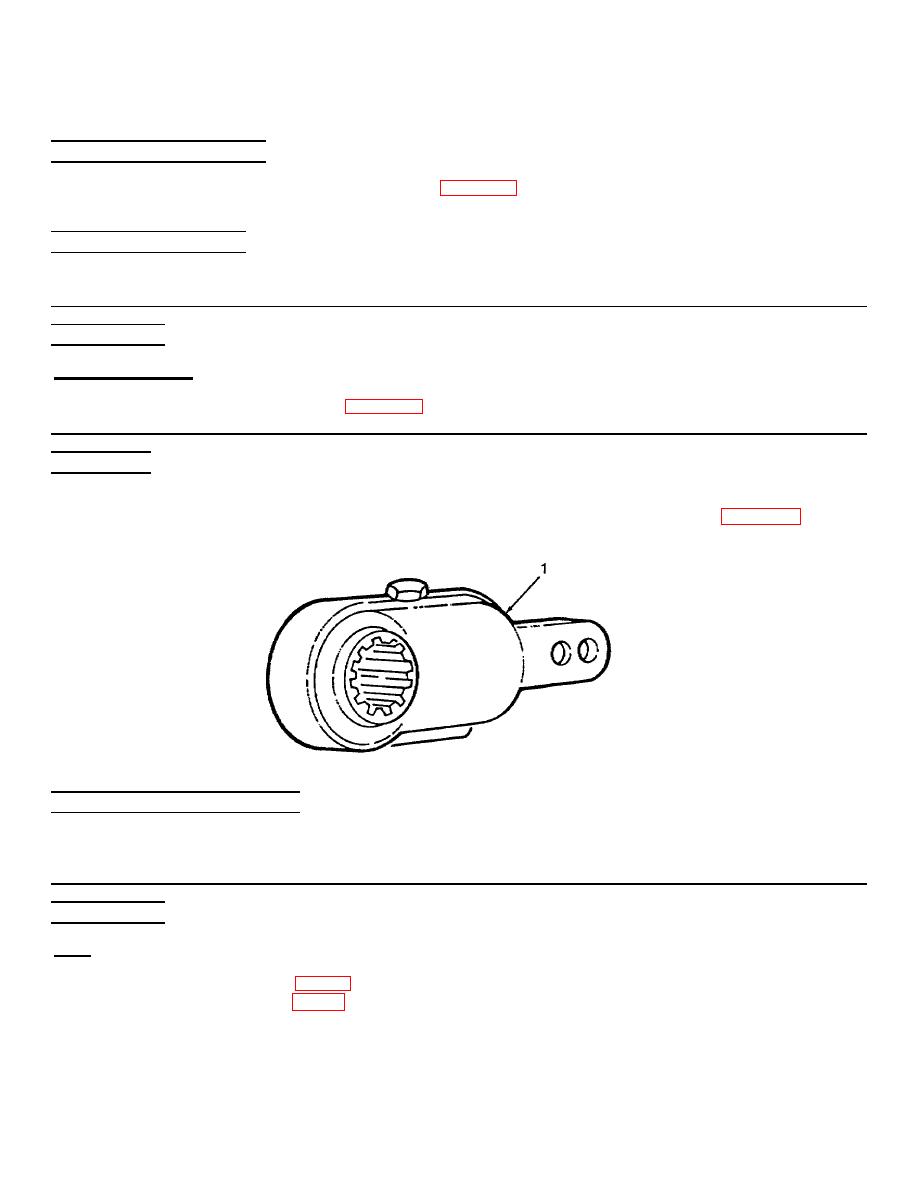

INSPECTION

Inspect slack adjuster (1) for wear, worn or broken gear teeth, broken/cracked housing, scoring, out-of-round, corrosion,

burrs, broken or bent locking tabs, and rounded off or stripped adjusting nuts. If defective, replace (para. 4-44) with new

slack adjuster during installation of s-cam.

4-47.

AIR CLEANER ASSEMBLY

This task covers:

a. Removal

c. Inspection

e. Installation

b. Disassembly

d. Assembly

INITIAL SETUP

Tools

General mechanics tool kit, item 16, appx. B

Torque wrench, 3/8" drive, item 17, appx. B

4-209