TM 9-2330-381-14

3.

Inspect tire for uneven wear, deterioration, weathering or dry rotting, defective tread, cuts, and leaks. If defects

exist, repair tire in accordance with TM 9-2610-200-20.

ASSEMBLY

1.

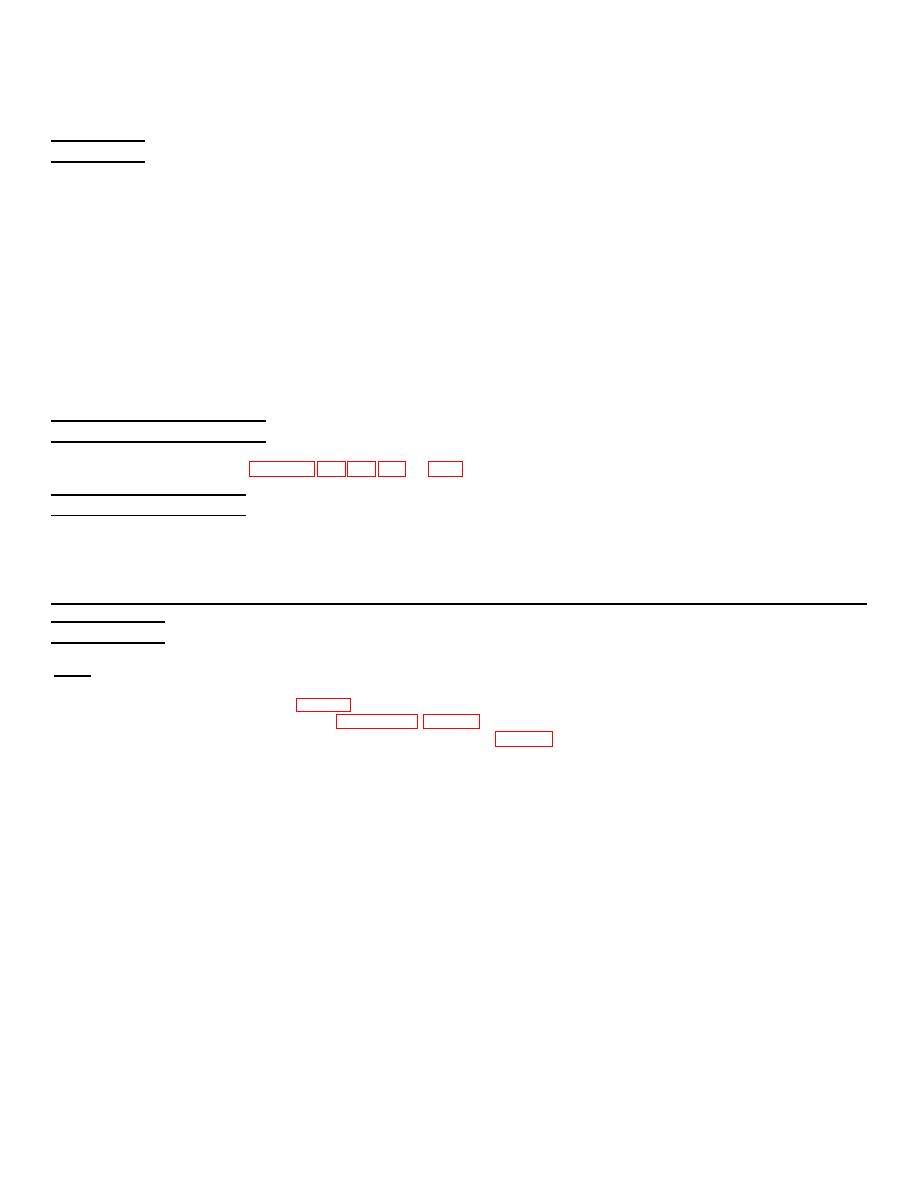

Using valve stem fishing tool, install valve stem (1) onto wheel (3). Ensure valve has been removed from inside

valve stem (1).

2.

Using two people, a bead breaker tire iron, and double-ended tire iron, install tire (2) onto wheel (3).

3.

Using an air compressor and inflator gage, inflate tire to reseal tire bead. Once tire bead is established, using a

pneumatic valve repair tool, insert valve into valve stem (1).

4.

Fill tire to 85 psi 5 psi (568 kPa 34 kPa).

5.

Pour water onto valve stem (1) and inner and outer beads of tire to check for leaks.

6.

Balance wheel using vehicle wheel balancer as required.

FOLLOW-ON MAINTENANCE

Install wheel onto semitrailer (para. 3-6, 3-7, 3-8, 3-9, or 3-10).

4-52. CONNECTING LINK

This task covers:

a. Removal

c. Inspection

e. Installation

b. Disassembly

d. Assembly

f. Urethane Bushing

Repair

INITIAL SETUP

Tools

General mechanics tool kit, item 16, appx. B

Urethane bushing removal/installation tool, figure F-18, appx. F

The following tools can be found in common tool kit no. 1, item 18, appx. B:

Torque wrench, 0-600 lb-ft,

Ratchet, 3/4" drive

3/4" drive

Extension light, 24 ft

Socket, 1-1/2", 3/4" drive

Machinists vise, 4"

Wrench, combination, 1-1/8"

Degreaser tank, 20 gal

Wrench, adjustable automotive

4-243