TM 9-2330-388-14

Table 4-1. Unit Preventive Maintenance Checks and Services (Cont'd)

Q - Quarterly

S - Semiannually

A - Annually

B - Biennially

H - Hours

INTERVAL

ITEM TO BE INSPECTED

ITEM

PROCEDURE: Check for and have repaired,

NO

Q

S

A

B

H

filled, adjusted as needed

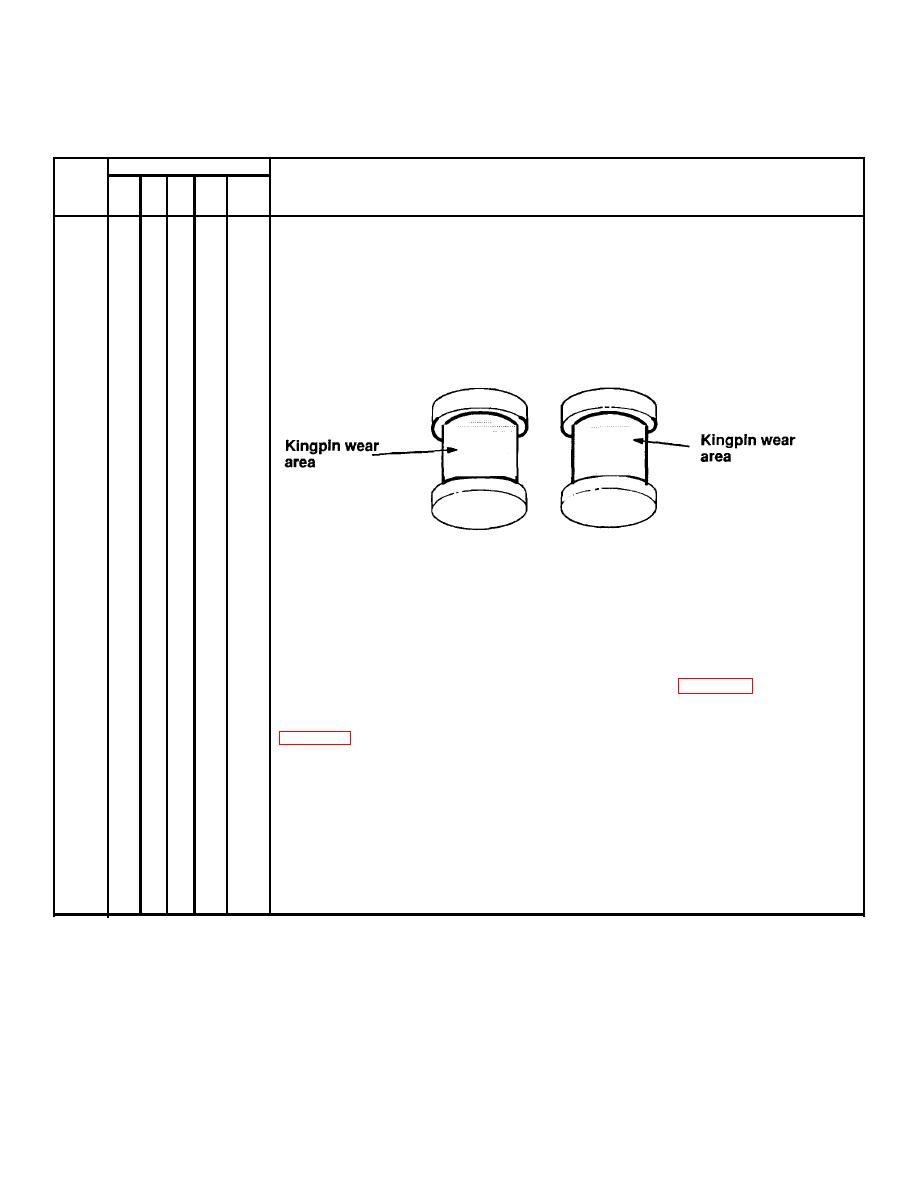

b. Even wear over the kingpin surface causing the diameter to be reduced by 1/16-

inch.

c.

When a crack of any size is noted anywhere on the pin or associated welds.

d. When a nick, chip, or gouge deeper than 1/8-inch is noted anywhere on the wear

surface of the pin.

e. Check air line glad hand coupling packing rings for damage. Replace if damaged.

5

Wheels and Hubs

a. Check for cracked wheels or hubs and missing or loose wheel nuts.

b. Check hub and drum for scratches, pitting, cracks, or other damage and check

bearing race inside hub for looseness. Replace if damaged, para 4-51.

c. Clean and inspect wheel bearings. Replace worn or damaged bearings. Repack,

6

Brakes

a. Check brake shoe lining thickness. Replace if lining is within 1/16-inch of rivet

heads. Check drum for damage or indication of overheating.

b. With air in system, check air line couplings for leaks. Tighten if loose. Replace if

damaged.

4-5