TM 9-2330-398-10

2-16.

GENERAL FUEL-HANDLING INSTRUCTIONS (continued).

WARNING

The operator must be alert for leaking and malfunctioning equipment. Stop all servicing

operations immediately at the first sign of leaks or malfunctions. Corrective action must be

performed by qualified technicians before resuming any operations. Failure to observe these

precautions may result in injury to personnel.

d.

SPILLS AND LEAKS. All spills must be cleaned up immediately. Suitable containers must be placed under hose

connections to collect leakage or spills.

e.

f.

BULK FUEL SERVICING HOSES. Whenever bulk fuel hose is required, remove the necessary lengths from

hose troughs and couple together as required.

g.

FUEL-DISPENSING NOZZLES. Make sure hoses are installed with correct fuel dispensing nozzles for the

operation intended. Refer to paragraph 3-11 to install fuel-dispensing nozzles.

h.

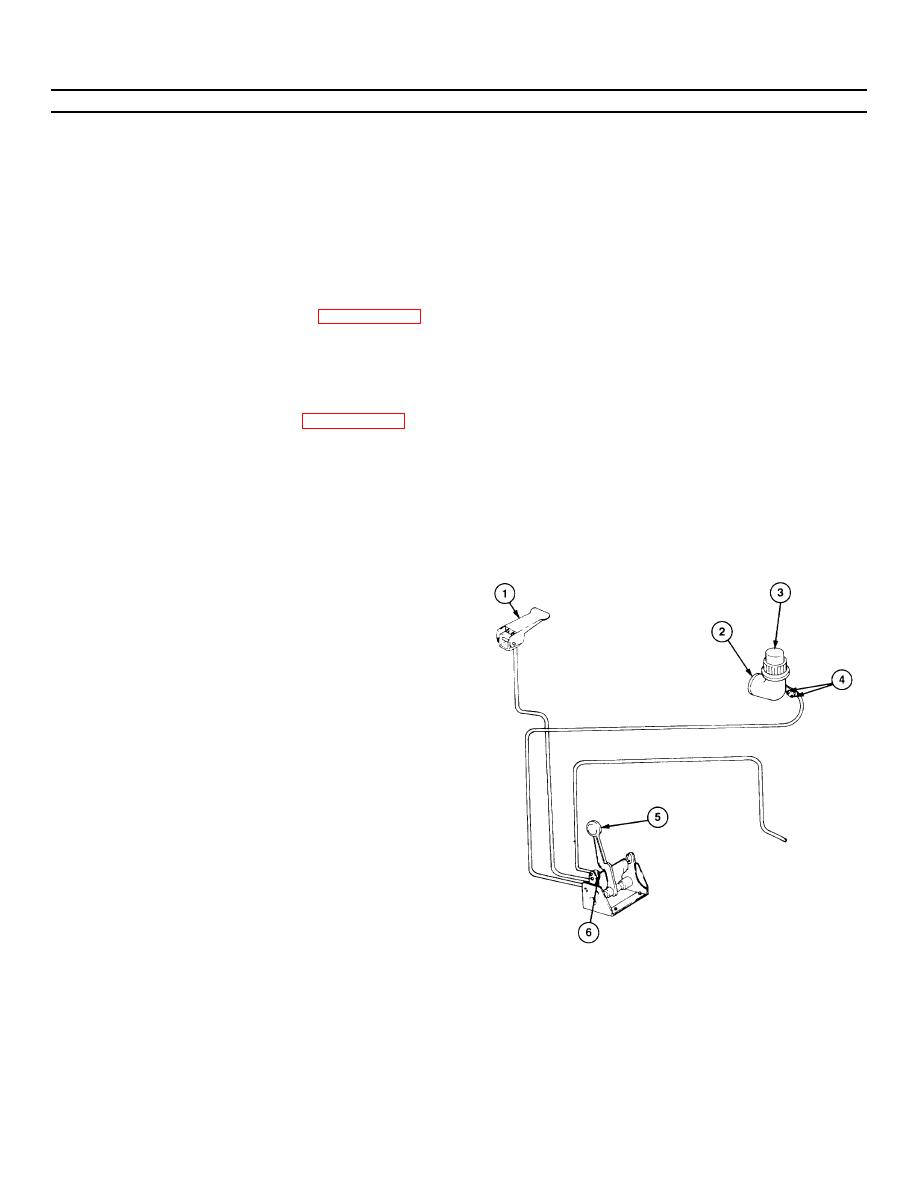

EMERGENCY VALVE OPERATION. The emergency valve (2) controls the tank outlet. The emergency valve (2)

and its vapor vent (3) are mechanically operated by the emergency valve A control handle (5) in the piping control

assembly. Engaging the emergency valve A control handle (5) opens the emergency valve (2) to permit fuel flow

to/from tank sump. At the same time, vapor vent (3) at top of tank opens to relieve pressure/ vacuum during

loading or unloading.

1.

Emergency valve (2) must be open for all

loading/unloading operations except top loading.

2.

In an emergency, close emergency valve (2) by

disengaging emergency valve A control handle

(5) (road side of semitrailer), or by pulling

emergency valve shut-off (1) (curb side).

3.

In the event of fire or explosion, either the fusible

nut (6) on emergency valve A control handle (5)

or the fuse plates (4) at emergency valve (2) will

melt, releasing emergency valve (2) and

automatically stopping fuel flow.

2-39