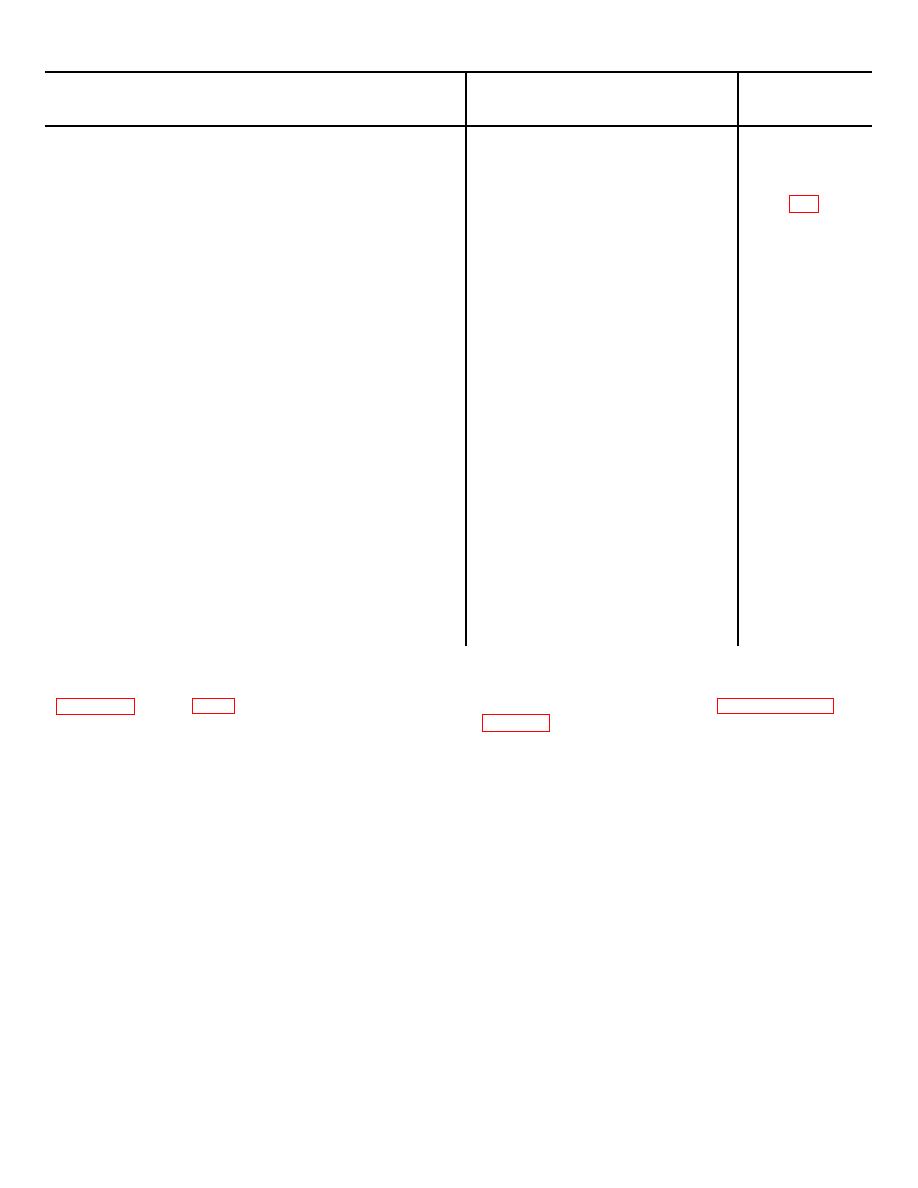

Table E-3. Qualification Procedure

Troubleshooting

Reference

Command

Response

(Figure No.)

1. Prerequisites for test (with engine not running).

a. Check oil in right angle drive

.Oil in right angle drive at proper

level ({see lubrication guide).

2. Engage hydraulic pump with clutch handle.

Clutch engages hydraulic pump.

3. Place bulldozer operating control handle in the RAISE

Moldboard elevates to full-raised

(R) position (Note: If moldboard is already in raised

position.

position and carrying hooks are engaged, disengage

carrying hooks).

4. Place bulldozer operating handle in the LOWER (L)

Moldboard lowers to ground

E7

position..

level

5. Place bulldozer operating handle in the RAISE (R)

Moldboard remains in mid

E-7

position and allow moldboard to raise to mid

position for one (1) minute

between ground level and carrying hook height, then

without the moldboard drifting

allow bulldozer operating handle to return to HOLD (H).

downward more than 1/4 inch

position. Allow moldboard to remain in mid

position for

one (1) minute.

6. Place bulldozer operating handle in the LOWER (L)

Moldboard lowers to ground

E-7

position and allow moldboard to lower to ground level..

level

Note. Use a stop watch to time the response of the next

step.

7. Place bulldozer operating handle in the RAISE (R)

Moldboard elevates from ground

E-7

position and allow moldboard elevate to the full raised

level to the full raised position

position..

within 5.0 to 6.0 seconds

8. Place bulldozer operating handle in the FLOAT (F)

Moldboard drifts downward to

E-7

position and allow moldboard to drift downward to

ground level.

ground level

9. Place bulldozer operating handle on RAISE (R) position

Moldboard elevates to the full-

E-7

and raise moldboard to full-raised position

raised position.

10. Disengage hydraulic pump with clutch handle.

Clutch disengages hydraulic

pump.

early model (M8A3) bulldozer.

For common

E-27. Schematic diagrams and locational views

troubleshooting routines, refer to paragraph 3-32 and

aids for the peculiar troubleshooting routines for the

AE-9