TM 9-3405-215-14&P

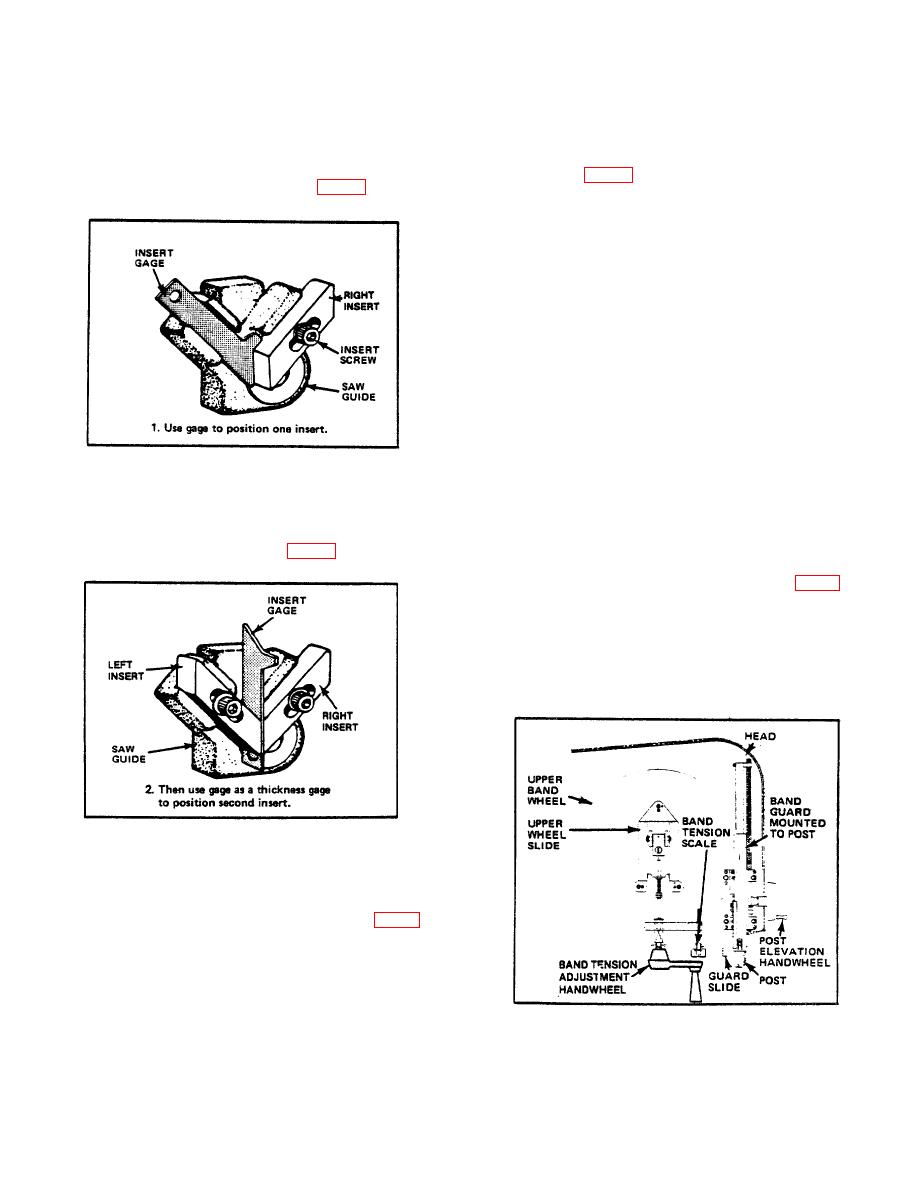

INSERT-TYPE SAW GUIDE ADJUSTMENT

BAND INSTALLATION

(1) Select guide blocks and inserts set marked for band

(1) Open band wheel doors.

Relax band tension.

width. Place right insert in milled slot. Tighten

Remove post band guard. Loosen left saw guide

screw lightly so insert will slide in slot and hold its

insert. See Fig. 8.

proper position when released. See Fig. 7.

(2) Unlock saw slot bar located below table front edge.

Move bar away from saw slot.

(3) Place band carefully over wheels and between saw

guide inserts. Band center should center on wheel's

crown face. Apply proper band tension. Tighten

saw guide inserts.

(4) Move table slot bar back into pos ition and lock. Re-

install post band guard and close wheel doors.

BAND REMOVAL

(1) Open band wheel doors. Remove post band guard

and unlock saw slot cover. Move bar so that it does

not cover saw slot. Release band tension.

(2) Loosen saw guide inserts and carefully remove

band. Slip band from wheels.

FIG. 7. POSITIONING RIGHT INSERT. UPPER

GUIDE BLOCK SHOWN.

BAND TENSIONING

(2) Select insert gage matching saw band. Place in

Band tension is applied by turning handwheel located

slot. Adjust insert to fit exactly into gage notched

below saw head. Tighten band to tension indicated on

end. Tighten insert screw. See Fig. 7.

scale to right of handwheel. Correct tensions are given for

bands 1/8-inch (3.2 mm) to 1 inch (25 mm). See Fig. 9.

Scale figures are recommended tensions. They are

based on most commonly used gages and pitches.

Reduce recommended tension when using bands with

coarser pitch or lighter gage. Increase tension when

using heavier bands.

FIG. 8. POSITIONING LEFT INSERT. UPPER GUIDE

BLOCK SHOWN.

(3) Place left insert in slot. Tighten screw lightly. Place

gage edgewise between both inserts. Lower insert

until it rests against gage. Tighten screw. See Fig. 8.

NOTE

INSERT-TYPE

GUIDES

ARE

RECOMMENDED

FOR

MAXIMUM

BAND SPEEDS OF 1300 FPM (390

m/min) FOR PRODUCTION SAWING,

OR UP TO 5000 FPM (1500 m/min) FOR

FIG. 9. BAND TENSION AND POST CONTROLS.

OCCASIONAL SAWING, USE ROLLER

GUIDES FOR CONTINUOUS SAWING

OVER 1300 FPM (390 m/min).

7