BEARING REPLACEMENT

REASSEMBLY

1.

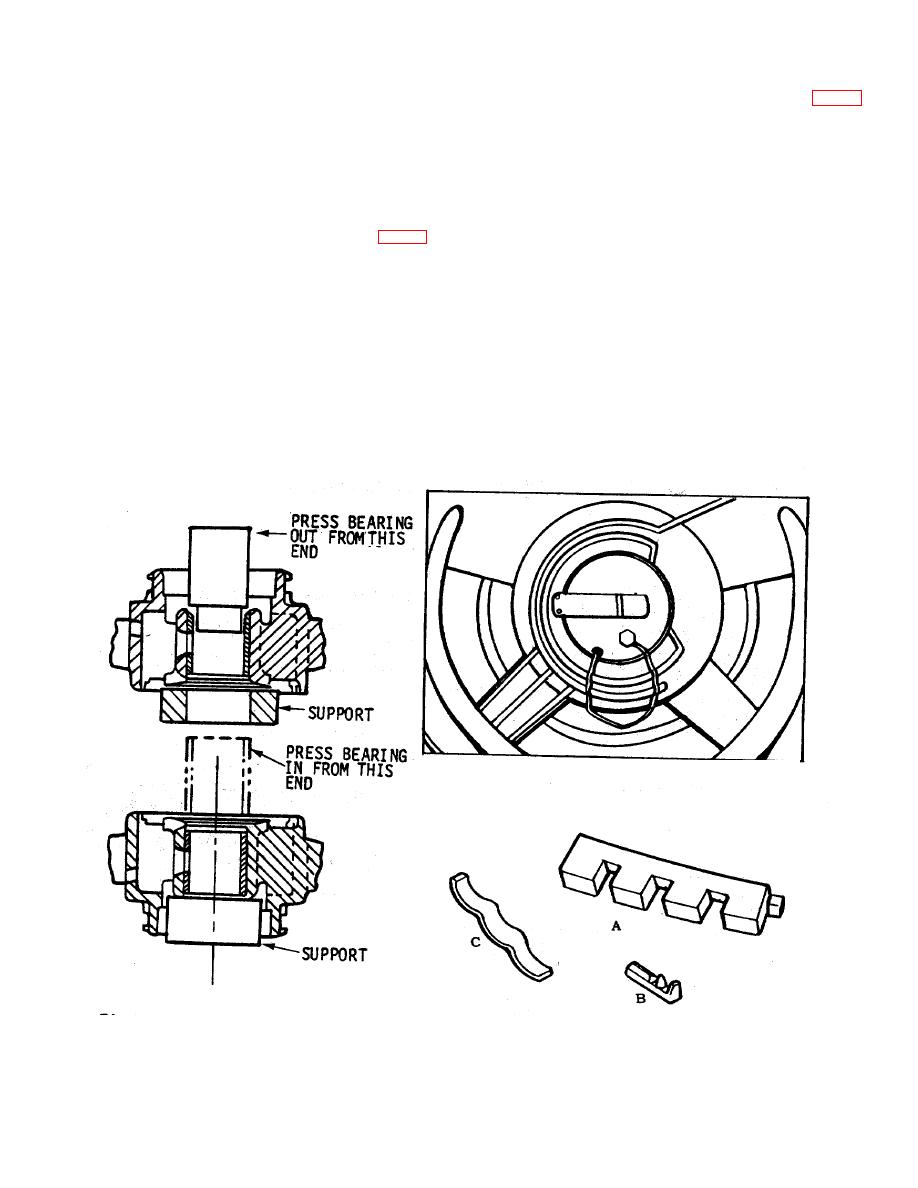

Support the outer face of the hub (see Fig. 6)

REMOVAL

the same as in removal, except use a support plate

without a hole.

1.

Pry off the oil-well cover on the inner side of the

2.

Press the bearing from the inner side of the end

end shield. Notice how the spring-steel thrust plate is

shield until it stops against the support plate.

keyed to the end shield at four points.

3.

Place the felt packing in its original position.

2.

Remove the end cap.

4.

On the pulley-end end shield; place the oil

3.

When removing the felt packing, notice its

slinger in the outside cavity; the sharp edge should be

arrangement for proper reassembly.

toward the end cap.

4.

On the outer side of the end shield (see Fig. 6),

5.

Press on the news end cap and oil-well cover.

support the bearing-hub inside nose with a smooth collar

Aline the locating mark on the oil-well cover with the

which has a hole slightly larger than the outside diameter

locating boss on end shield (see rig. 7). Use a sealing

of the bearing.

compound on those surfaces where the cap and the

5.

From the inner side, press out the bearing with a

cover mate with the end shield. Be sure the spring-steel

tool having a guide to fit into the bearing and an outside

thrust plate is properly located before assembling the oil-

diameter slightly smaller than the outside diameter of the

well cover.

bearing.

6.

Check for any wobble of the end shield face

NOTE FIG: 8: The large wick A is a reservoir; the P

fitting against the stator shell. If wobble is over 0.004

shaped double feeder wick B supplies the sleeve and

inch gage reading, reface this surface. 00 NOT ream

thrust bearings; the narrow wick C returns oil from the

the bearing to eliminate wobble. Follow the same

outboard end of bearing to the main storage wick.

refacing procedure when repairing tight motors.

Fig. 7. Proper alinement of oil well cover on end shield

Fig. 6. Bearing replacement

FIG. 8. Oil reservoir and feeder wick

42