TM 9-3419-234-14&P

1-2

SETTING UP

CHAPTER 1 - THREADING MACHINE--MODEL C

SECTION I ..OPERATING INSTRUCTIONS

a.

Die Head and Leadscrew Trip Mechanism

1-1

INSTALLATION

NOTE It is necessary to follow these instructions

when making all set-ups and whenever a change is made

in thread length produced on the workpieces or whenever

a.

Foundation

the die head is adjusted for a diameter change. This also

No special foundation is required, however, a level

applies even for a very small ( 005") diameter adjustment

concrete base is recommended The holes provided in the

bottom of the bed are used to secure the machine in its

when the machine is equipped with a Hardened and

protective crating for shipment If desired, these holes can

Ground Die Head.

be used to bolt the machine to the foundation.

b.

Handling

If possible, move the unit to its site of installation

before removing its protective crating or skids. Rollers

may be used under the skids but never in direct contact

with the bed Remove the crating and carefully place the

unit into position making sure the machine or its

components are not damaged.

c.

Cleaning

Remove the rust preventive from all machined

surfaces and operating parts Precautions should be taken

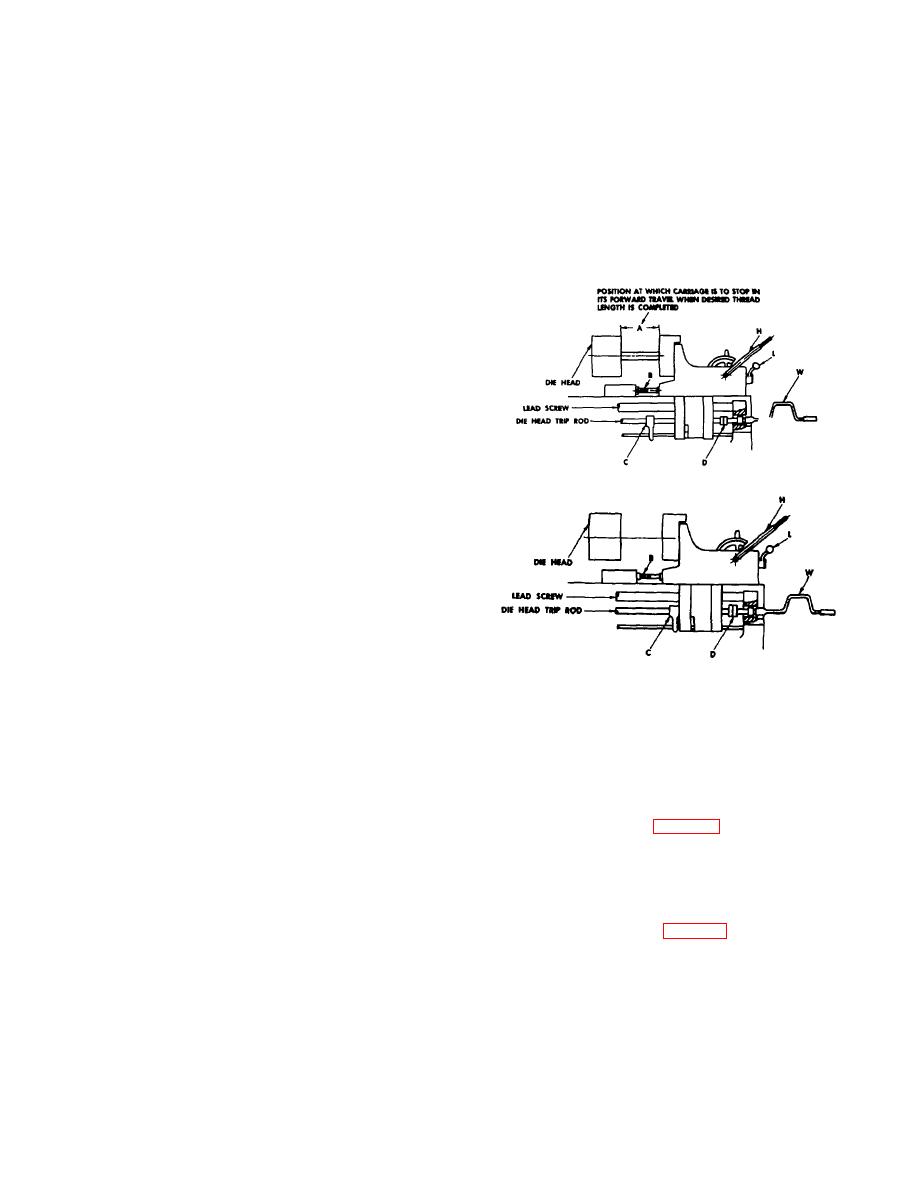

FIG 1

to prevent cleaning solvent and slush from entering the oil

reservoir or lubricating devices Remove all dirt and grit

accumulated in transit. After cleaning, apply a light film of

oil to all machined surfaces and operating parts to prevent

rusting.

d.

Leveling Machine

If the base provided for the machine is level the

machined pads on the bottom of the bed will sufficiently

level the unit. Precision leveling may be obtained by

placing shims under the machined pads.

FIG 2

e.

Lubrication

The headstock and various oiling points of the

16, for slowest spindle speed. The spindle must be

machine are prelubricated prior to shipment, however,

stopped before any further adjustments are made.

before placing the machine in operation, inspect the oil

sight gauges, No. 101, Figure 19, Page 19, and on the

left or right hand threading. See Lead Screw.

headstock. If additional oil is required it may be added

(3) Install chaser holders, chasers and adjust die head

through filler cups located on the headstock and carriage

for correct diameter.

fronts Use Ml L-L-10324, Oil Lubricating, Gear.

position with die head open, using wrench W.

f.

Electrical Installation

(5) Grip sample workpiece in carriage front or other

Install main line disconnect (not supplied unless on

holding device on the machine to determine position A ,

special order) and make electrical connections to motor

Figure 1.

starter by referring to the wiring diagram supplied. Check

(6) Advance carriage by means of lever or handwheel

input electrical supply, being certain it agrees with motor

H, to position A shown on Figure 1. If necessary, adjust

and control specifications. Jog the start-stop switch

screw B to clear carriage when positioned at A. Die Head

allowing the spindle to revolve several revolutions. Inspect

must be open.

all parts for freedom of operation. As you face the

machine, the die heads should be revolving counter-

clockwise for right hand threading. If rotation is incorrect,

simply reverse the two power line electrical leads at the

motor starter.

2