TM 9-3419-234-14&P

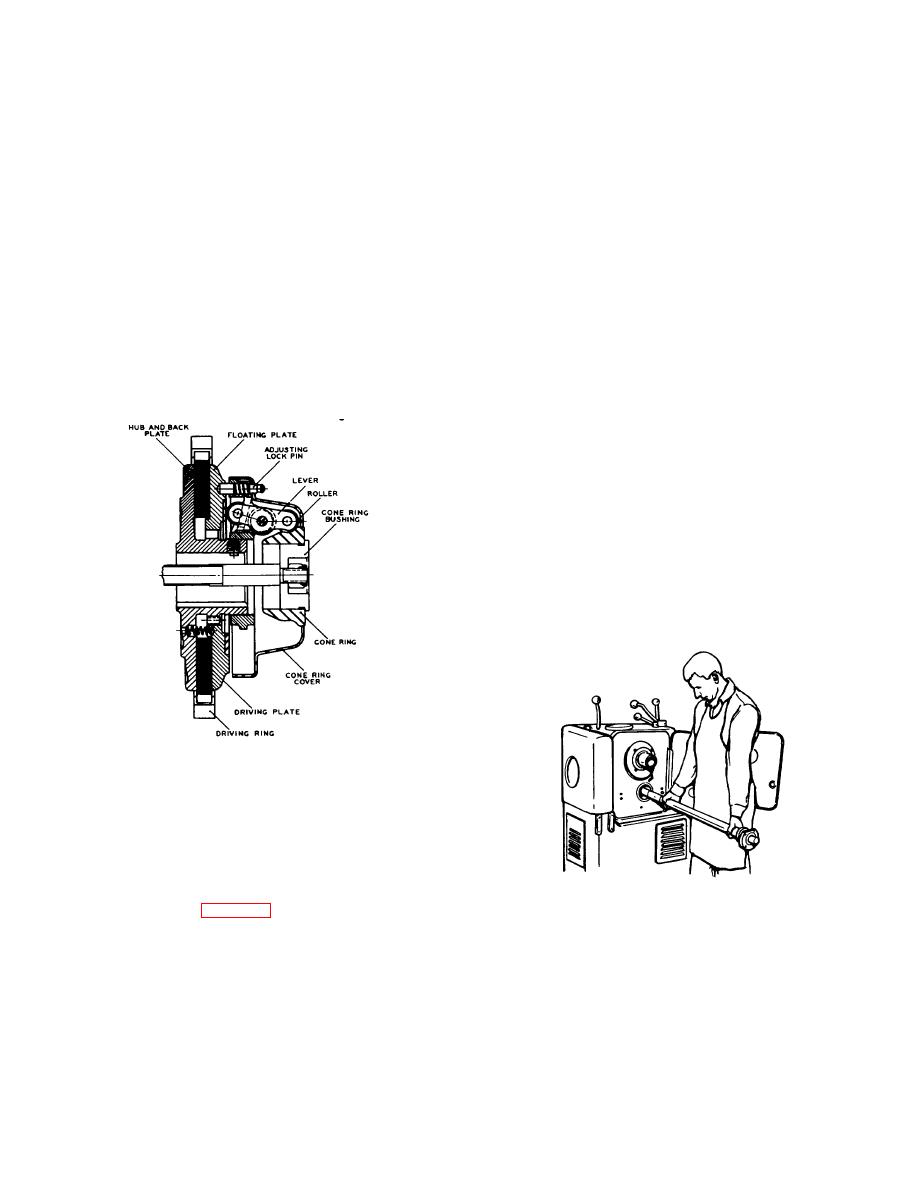

the cone ring cover and cone ring assembly by one

1-3 ADJUSTMENTS

increment until the proper tension is obtained.

a. Headstock

(5) If proper tension cannot be gamed through

(1) Internal adjustments will seldom be necessary,

adjustment, the sectionalized driving plate is excessively

however, if required, the repair should be made by a

worn and will require adjustment. The driving plate can

mechanic skilled In making such an adjustment.

be exposed for replacement by removing the cam

(2) Excessive spindle end play may be eliminated by

bushing and unscrewing the cone ring, cone ring cover

tightening the spindle bearing lock nut, #79, Figure 13,

and floating plate from the hub and back plate.

Page 15.

(6) After adjusting the driving plate or replacing it,

(3) First, loosen the spindle bearing lock nut lockscrew.

additional adjustment to the clutch for tension will be

Rotate the lock nut clockwise until all end play is

required.

eliminated, then tighten the lock screw. Before placing

the machine in operation after such an adjustment is

c. Leadscrew

made, make certain the spindle revolves freely.

(1)

In many applications, Leadscrew Threading are

CAUTION. An over adjustment could result in

used to thread workpieces requiring relatively short thread

damage to the machine.

lengths. After an extended period of operation, the

leadscrew used to control the carriage movement in

b. Clutch

producing these threads may wear sufficiently to cause

(1) After extended service, the function type dutch,

lead error.

Figure 4, may need adjustment to restore the original

(2)

For this reason, the leadscrews on all machines

operating efficiency.

were designed to allow them to be reversed or turned end

for end. The section of the leadscrew which received little

usage can be repositioned to control the movement of the

carnage and restore lead accuracy.

(3) When threads are being produced in lengths which

require the use of the entire leadscrew, the purchase of a

new leadscrew Is highly recommended if close tolerances

are to be maintained without difficulty.

(4) To reverse the leadscrew, it is necessary to remove

the entire leadscrew assembly from the machine. This

can be accomplished by removing the lower leadscrew

change gear and the bearing thrust plate. The lead-

Figure 4

(2) To determine the proper clutch tension, shut off the

power and engage the clutch several times. When

correctly tensioned, there will be a definite snap to the

clutch lever when engagement is made.

(3) To increase clutch tension, release the clutch, pull

the spring loaded adjusting lock pin outward and revolve

the cone ring cover and cone ring assembly in a

clockwise direction, Figure 4. A series of adjustment

Figure 5

holes are provided around the outer face of the tension

plate.

For best results, revolve the assembly in

increments of one space at a time.

(4) After adjusting the cone ring cover and cone ring

assembly by one increment, re-engage the adjusting lock

pin with the floating plate. Engage the clutch and check

for proper tension by operating the machine under power.

No slipping should occur. If required, continue to adjust

6