TM 9-3419-234-14&P

(7) Close leadscrew nut with lever L with carriage in

(1) When setting up a Model C Non-leadscrew Machine,

position A and with spindle stopped. If leadscrew nuts

the important thing Is to grip the workpiece at exactly the

will not engage, rotate spindle by hand until leadscrew

same position each time. This can be easily done

nuts will engage at position A .

through the use of an automatic work stop, Figure 22,

Page 22, or by measuring the workpiece each time one is

(8) Place a chalk or pencil mark at a convenient place on

gripped

both the carriage and bed as a reference for further use

(2) Grip a sample workpiece in the vice jaws leaving

so that carriage can be moved away from and returned

to position A .

sufficient clearance so the carriage will not contact the die

head upon completion of the thread length.

(9) Adjust screw B to contact leadscrew trip rod in

(3) With the die head closed, advance the carriage by

carriage.

means of the handwheel until the workpiece contacts the

(10) Open leadscrew nuts by means of lever L and move

stamped surface of the chasers. Place a chalk or pencil

carriage away from die head by means of the handwheel

mark on the carriage as a reference mark.

H. Do not close die head.

(4) Remove the workpiece from the grips and continue

(11) Readjust screw B approximately 8" closer to carriage

advancing the carnage toward the die head. Refer to the

and lock the screw.

mark placed on the carriage and measure until the

(12) Remove sample workpiece from grips.

predetermined thread length is reached. This position is

(13) Start spindle revolving with the die head open and

the point at which the die head should trip open and is

engage leadscrew nuts with lever L . This will advance

referred to as A in Figure 1.

the carriage toward the die head until screw B pushes

(5) Wrench W Is then used to adjust the trip rod nut C

the trip rod in the carriage sufficiently to open the

until the die head trips open. When adjusting the trip rod

leadscrew nut.

nuts, make certain the carriage does not move from

position A .

Check the reference lines placed on the carriage and

(6) The rear trip rod nuts may be positioned to close the

bed to make certain carriage stopped at position A. If

head at any point during the rearward travel of the

necessary, re-adjust screw B and repeat trials until

carriage.

carriage will stop at position A

(15) Engage the leadscrew and permit the carriage to stop

and, with the die head revolving, advance the carriage

automatically at position A. Hold carnage in this position

until the die head trips open.

and close die head manually. With the die head closed

(8) When satisfied with the operation, place the spindle

and carriage in position A, adjust the trip rod nut C with

wrench W until nut C contacts carriage as shown in

speed levers on the spindle speed required for the job

Figure 2.

and begin production.

(16) Continue turning wrench W to force nut C against

CAUTION Check operation of machine through

carriage until die head trips open. Make certain that the

several cycles before actual threading.

carriage does not move from position A when die head is

being tripped open.

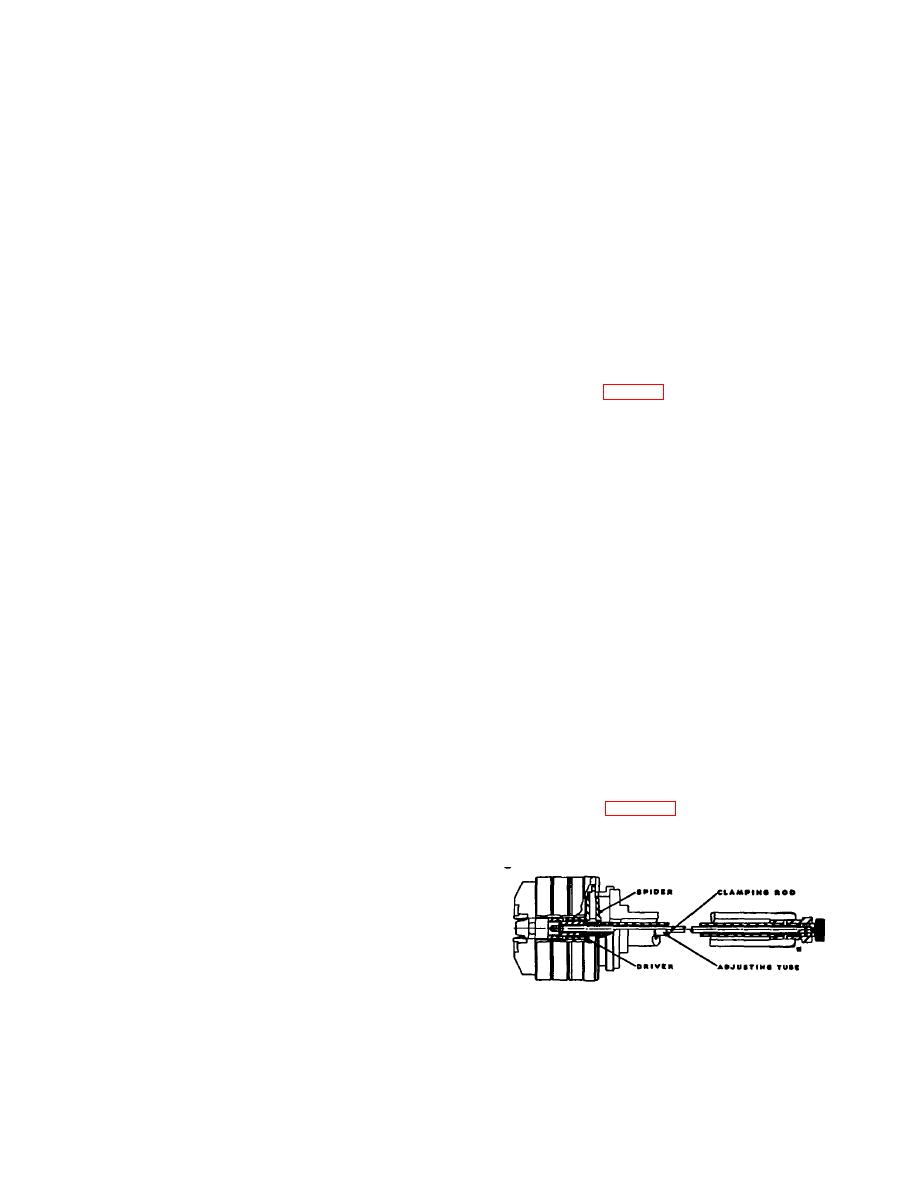

c. Pipe end Nipple Machines

(17) Return the carriage to position desired for loading

(1) When setting up a 10C or 16C Pipe and Nipple

and unloading workpieces, then set nut D to close die

Machine, the only operation necessary is to determine

head when the carriage Is returned to this position.

correct thread length.

(18) With die head closed and spindle revolving at slow

(2) The 10C and 16C Machines are equipped with

speed, engage the leadscrew and permit the carriage to

Internal Trip Pipe and Nipple Threading Heads designed

advance to and automatically stop at position A. If

to thread, ream and chamfer simultaneously through the

adjustments are correctly made, the die head will trip

use of a reamer, Figure 3. Head opening is effected

open an instant (fraction of a second) before the

through an internal trip mechanism actuated by the pipe

leadscrew nuts open.

pushing the reamer rearward during the threading

Note: It is important for the leadscrew nuts to trip

operation.

open instantly after the die head opens, because any extra

overtravel of the carriage after the die head opens will jam

the die head trip mechanism and damage the machine.

be used for the job.

(20) Check operation of machine through several cycles

without threading workpieces to make certain machine

functions correctly at normal spindle speed.

CAUTION

Figure 3

Check operation of machine through several cycles

without threading workpieces each time adjustments are

made to the die head and leadscrew trip mechanism.

b. Non-Leadscrew Machines

3