TM 9-3431-254-14&P

Manufacturer's Instruction Bulletin in the back of

this manual.

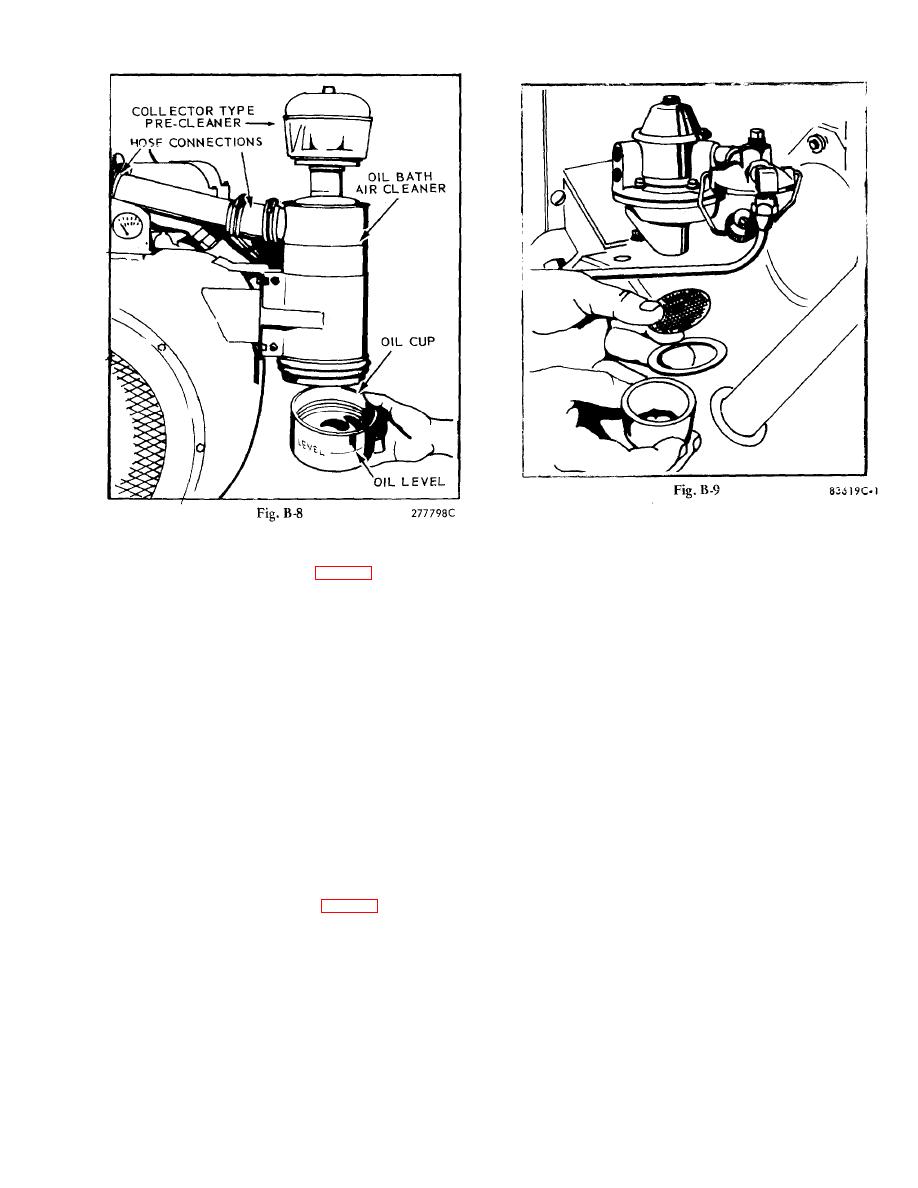

PRE-CLEANER

IGNITION SYSTEM

The collector type pre-cleaner, mounted to the top of

the air cleaner as illustrated in Fig. B-8, removes the

A battery ignition system is standard equipment on

larger dirt and dust particles before the air reaches

this model of engine. The distributor is of the auto-

the main air cleaner.

matic advance type and it is driven off an engine

speed shaft through a pair of two to one ratio gears,

Clean bowl regularly of accumulated dust and dirt.

thus driving the distributor rotor at one half engine

Do not use oil or water in pre-cleaner, this must be

speed in a counter-clockwise direction when viewed

kept dry.

from above.

Daily attention to the air cleaner and pre-cleaner is

one of the most important considerations in prolong-

The running spark advance of the engine is 23 and

ing engine life.

the distributor is fully advanced at 2000 R.P.M.

Engine must be running at 2000 R.P.M. or over, when

GASOLINE STRAINER

checking or adjusting spark advance.

The gasoline strainer is very necessary to prevent

sediment, dirt and water from entering the carburetor

tion coil furnished are products of either the Delco-

and causing trouble or even complete stoppage of the

Remy Company or Prestolite Company It is suggested

engine. This strainer has a glass bowl and should be

that when replacement of any of these parts becomes

inspected frequently, and cleaned if dirt or water are

necessary, that the replaced parts be of the same

present.

manufacture as the other components.

swing wire bail to one side, see Fig. B-9. There will

TIMING

be less danger of breaking the gasket if the bowl is

given a twist as it is being removed. Clean bowl and

screen thoroughly. Replace gasket if it has become

FIRING ORDER

damaged or hardened. Repair kits are available for

The firing order of the cylinders is 1-3-4-2, and the

service replacement, refer to parts list in rear of

battery type distributor rotates at one-half engine

manual.

speed, as is the case with conventional 'in line' en-

gines. The intervals between the firing of the cylin-

CARBURETOR ADJUSTMENT

ders is 180. No. 1 cylinder is the one nearest to the

The main metering jet in the carburetor is of the fix-

flywheel in the left bank of cylinders, when viewed

ed type, that is, it requires no adjustment. The idle

from the flywheel end of the engine. No. 3 cylinder is

needle should be adjusted for best low speed opera-

the other cylinder in this bank. No. 2 cylinder is the

tion, while carburetor throttle is closed by hand. For

one nearest to the flywheel in the right bank of cylin-

illustrations and more information, see Carburetor

ders and No. 4 is the other cylinder in this bank. The