TM 9-3431-254-14&P

Every 200 hours, add a small amount of high melting

point grease to breaker arm rubbing block, or oil the

cam wick.

excessive lubrication. oil that may get on the

Avoid

contact points will cause them to burn.

GENERATOR

A 12

equipment, unless otherwise s;pecified. The generator

is manufactured by either the Delco-Remy Company

or Prestolite Company.

Every 50 hours of operation, add 3 to 5 drops of

medium engine oil into the oil cap at both ends of

the generator.

ELECTRICAL

WIRING

CIRCUITS

Beginning with engine serial No. 3979807, the stan-

dard wiring circuits for all electrical equipment is

for n e g a t i v e g r o u n d polarity, instead of the pre-

viously furnished positive ground.

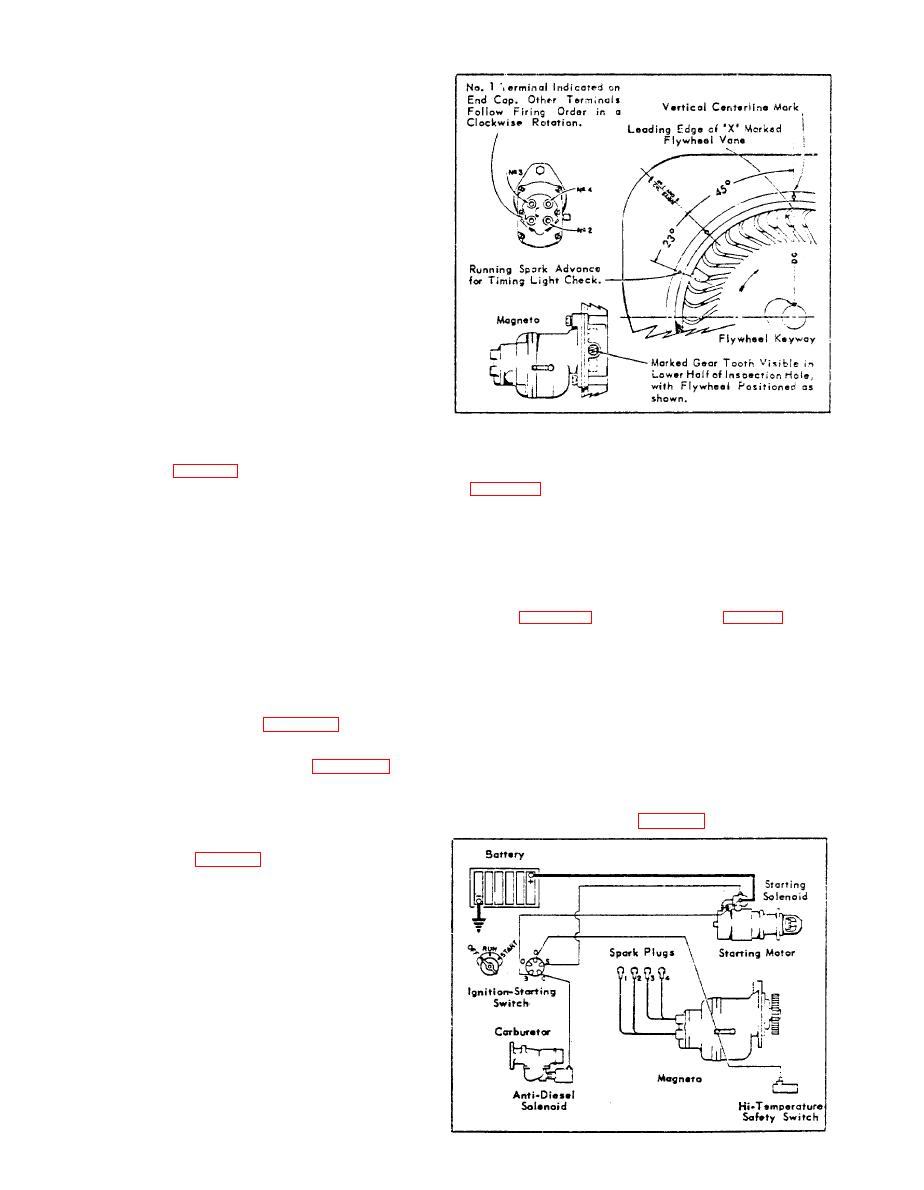

MAGNETO TIMING DIAGRAM

The wiring diagram, Fig. B-15, illustrates a negative

hole in gear cover. See Magneto Timing Diagram,

ground circuit. To wire equipment that has a posi-

Fig. B-16. Securely tighten nut and capscrew for

tive ground polarity; reverse terminal connections at

mounting magneto.

The No. 1 terminal is identified on the magneto cap.

The terrninals follow the proper firing order of 1-3-4-2

positive ground generator and regulator in

in a clockwise direction viewing the cap end. The

Do not use

a negative ground circuit, or vice versa. Polarity

leads from the magneto should be connected to spark

does not affect starting motor, coil and distributor.

plugs of corresponding numbers, see Firing Order

MAGNETO

TIMING

When magneto is properly timed the impulse coupling

For engines furnished with magneto ignition in place

will snap when the `DC' - `X' marked vane of the fly-

of distributor ignition, timing is accomplished in the

wheel lines up with the mark on flywheel, which in-

following manner:

dicates the centerline of the No. 1 and 3 cylinders.

1. Expose timing marks on flywheel and shroud. Refer

This can be checked by turning crankshaft over slow-

ly by hand. The impulse will also snap every 180 of

flywheel rotation thereafter.

Position No. 1 piston on compression stroke, as

2.

The running spark advance is 23. To check timing

with a neon light, the advance is indicated by a hole

With No. 1 piston on compression stroke turn en-

3.

on the flywheel shroud, 23 before centerline of t h e

gine over past top dead center, until the leading

edge of the `X' marked vane on the flywheel is in

l i n e with the vertical centerline mark on the

this position (flywheel keyway will be on top).

Remove inspection hole plug, located in gear cover

4.

at magneto mounting flange.

5. Assuming the magneto is removed from the engine;

set magneto for spark discharge to the No. 1 ter-

minal. This is accomplished by use of a short

stiff length of wire placed into the No. 1 terminal

socket and bent to within 1/8 inch of the magneto

frame. Then turn the magneto gear in a clockwise

rotation, tripping the impulse coupling, until a

spark is observed between the wire and frame. Re-

tain gear in this position.

6. Place gasket on flange and mount magneto to en-

gine, meshing the gears so that when magneto is

assembled, the gear tooth marked with an `X' will

be visible through the lower half of the inspection

MAGNETO

IGNITION

-

WIRING

DIAGRAM

B-16