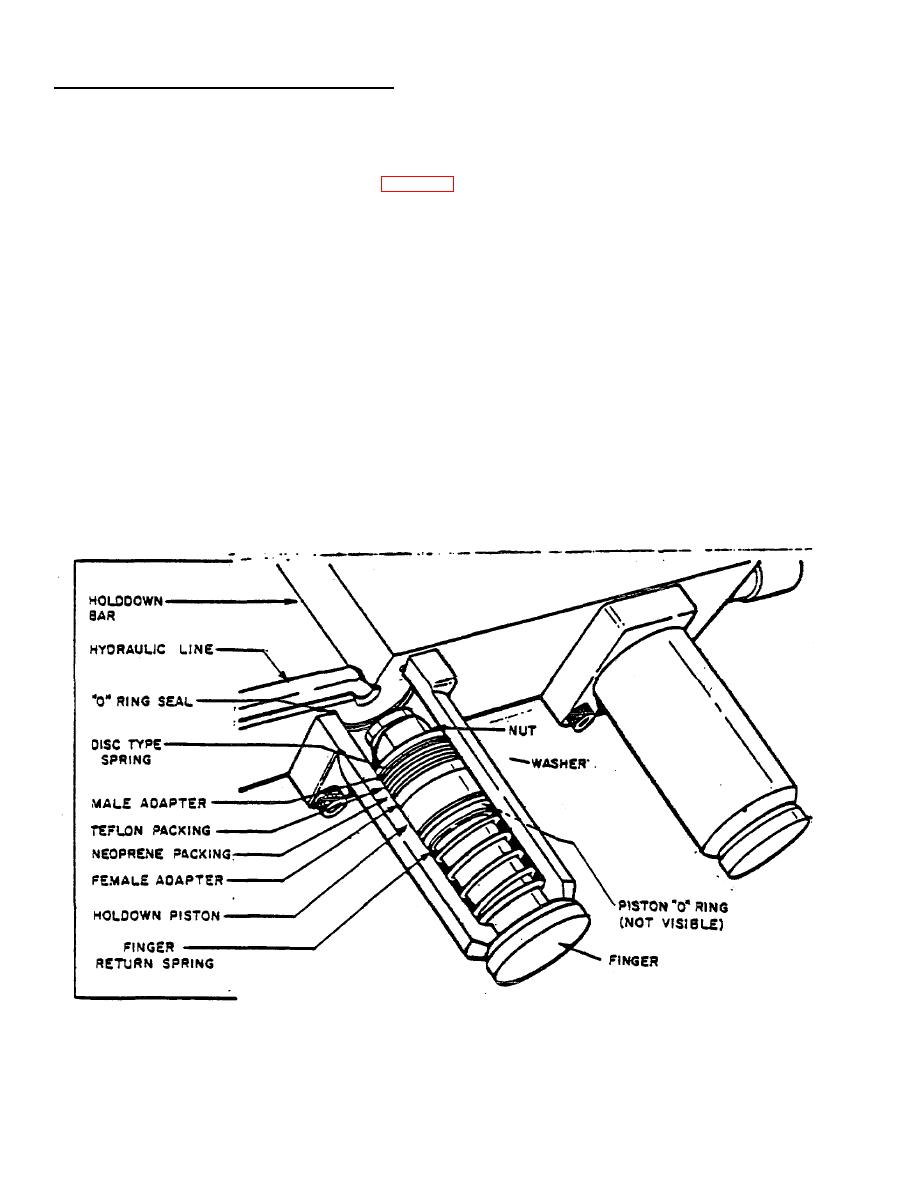

HYDRAULIC HOLDDOWN FINGER ASSEMBLES

In order that we may utilize to the fullest extent the benefits of a hydraulic holddown system, we have developed a

type of holddown finger that is trouble-free and easy to service.

Because of the difficulty in maintaining leak-free Joints in high pressure hydraulic systems, all connector tubes and

Joints have been eliminated between the fingers (Figure 23) and each finger can be removed and replaced independent of

the others. Should the occasion arise where a replacement finger is not immediately available, a damaged finger could be

replaced with a flat steel plate and a gasket (available from the factory).

The distance from the blade cutting edge to the holddown finger is adjustable. Your shear was shipped from the

factory with the holddowns in normal position. For making very narrow cuts, any of the holddown assemblies can be

rotated 180 to decrease the distance. Since this reduces the holddown "leverage", when shearing capacity plate under

one holddown, it should be adjusted to the "far away" position.

The holddown finger consists of a casting with the bore honed to provide a sliding surface for the packings on the

plunger. The hydraulic pressure actuating the plunger in its travel is sealed from leakage around the plunger by a new

chevron type of '"Teflon" packing for impact sealing. Action of a heavy spring is utilized to return the plunger to its "up"

position after the pressure is released.

While the lower part of the plunger is carefully machined in order to avoid the possibility of indenting or marking

polished surfaces, special provisions in the form of molded Urethane cups can be furnished at extra cost to insure mar-

free work.

Occasionally, a holddown finger will develop a leak. If this occurs, insert a piece of material of capacity thickness

under each finger of the shear, and operate the shear through 8 or 10 cycles. This should reseal the "'Teflon" packing. If

the finger continues to leak, chances are that some dirt or residue

Figure 23. Hydraulic Holddown Finger Assembly

24