in the hydraulic system has marred the packing, causing the leak. If this is the case, the entire holddown. system should

be drained, flushed and cleaned and new finger packing installed. It is important that the system be cleaned before any

new packing is installed in the holddown fingers. The holddown system can be drained through the drain plugs. The

remaining oil can be removed by operating the shear a few times which will force it out through the bleeder valve at the left

end of the holddown bar.

For satisfactory operation of the hydraulic holddown system, make certain you only use the type of oil specified in the

lubricating instructions. Ii the oil is too heavy, the plungers will not retract properly and, in some instances, full holddown

pressure cannot be obtained.

FRONT OPERATED MICROMETER BACK GAUGE

The back gauge arrangement on the 0200, 0300, 0400, and 0600 series shears is manually operated by a crank, and

the standard back gauge range for these shears is 36". Back gauge dials are graduated in fractions to 1/64" or in

decimals to .002"

When adjusting the back gauge for a certain setting, for example 4", always move the back gauge beyond that

setting, perhaps to 5" or 5-1/2", and then come back to desired setting. In this way, any backlash in the mechanism will be

eliminated and an accurate back gauge setting can be made. After the setting is made, it should be locked in position by

the hand operated binding screw on the side of the back gauge dial bracket.

The 0800 and 1000 series shears are provided with a motorized front operated back gauge as standard equipment

(Figure 24) and have a back gauge range of 48". The motorized back gauge and 48" range may be furnished as an

accessory on all other sizes of shears.

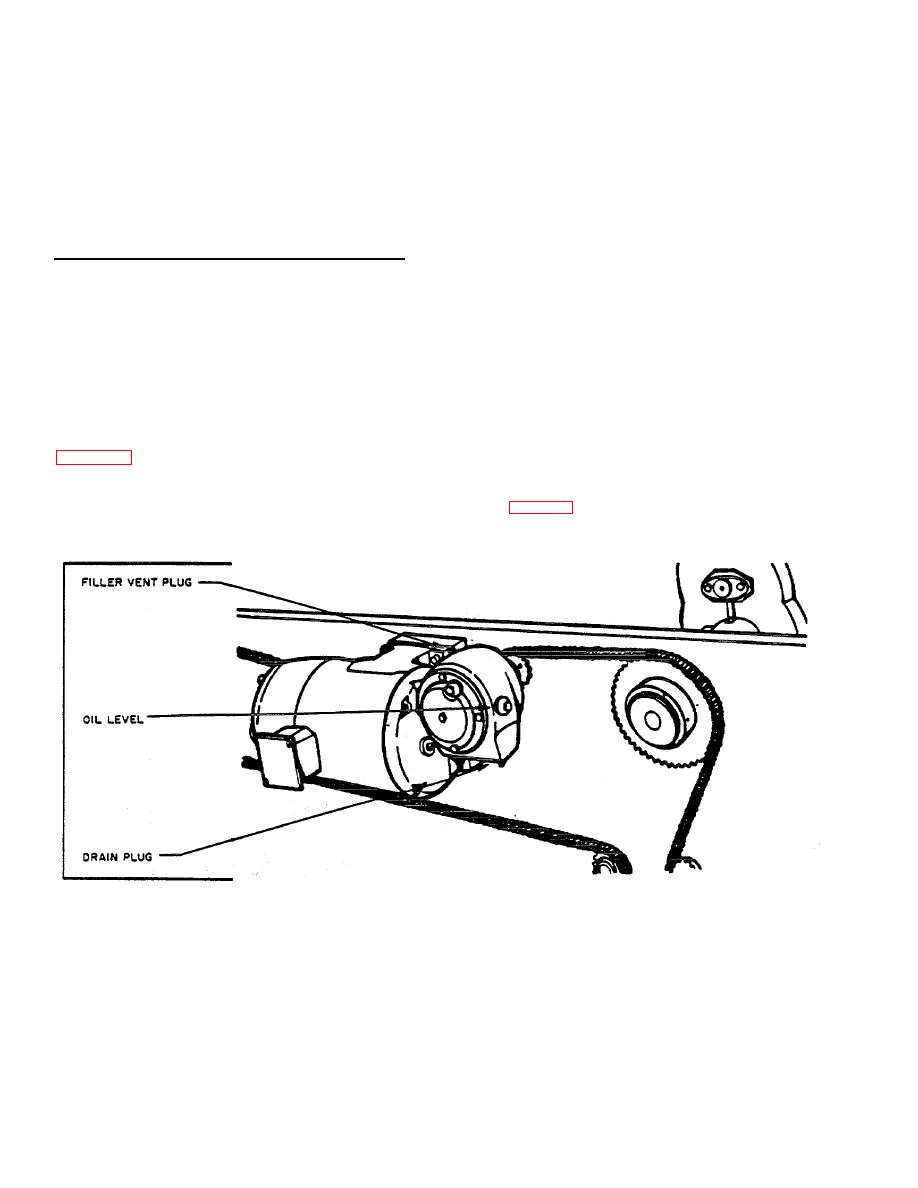

The motorized back gauge is equipped with two limit switches (Figure 2) for limiting travel in either direction and an

automatic brake to lock the setting.

Figure 24. Motor and Drive for Front Operated Motorized Back Gauge

25