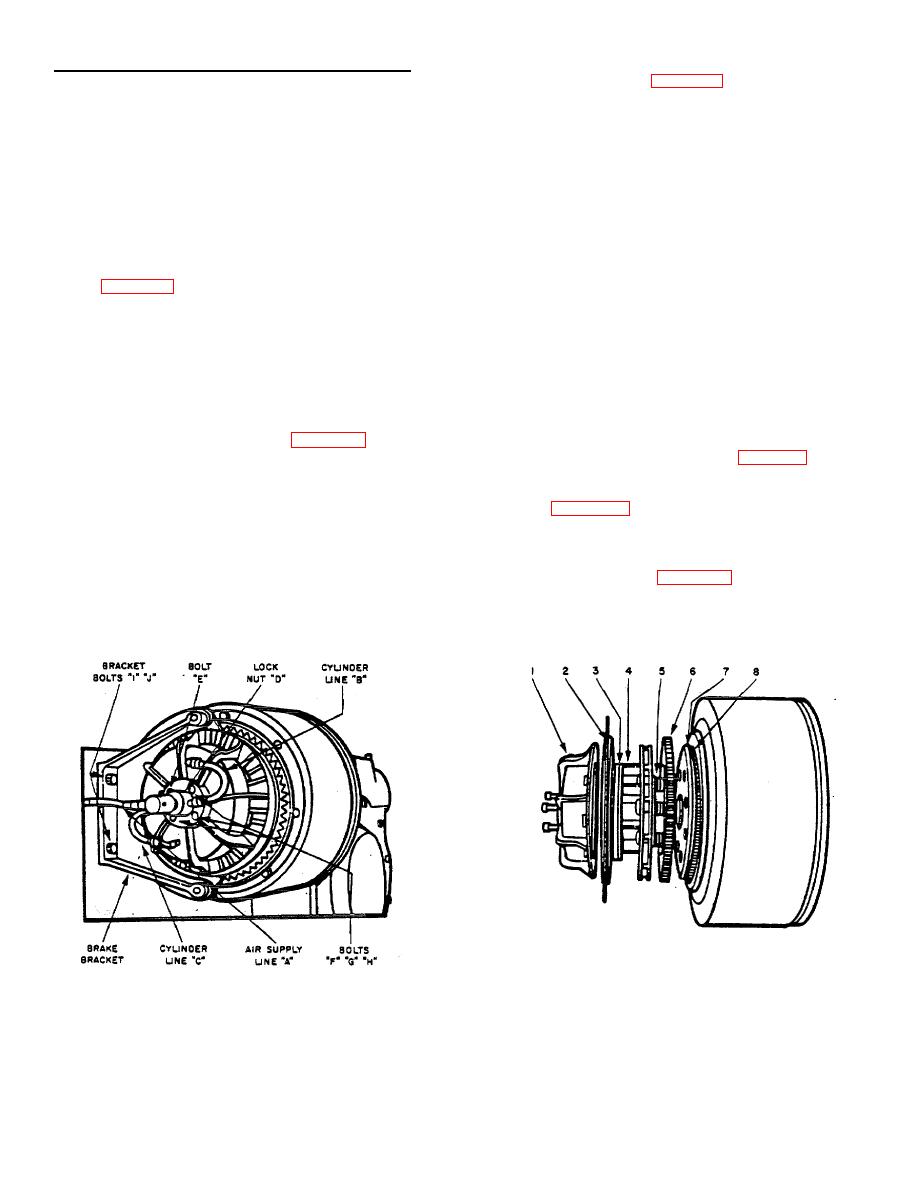

COMBINATION AIR CLUTCH AND SPRING BRAKE

Your shear has been provided with the finest clutch and brake system in the industry (Figure 20).

The unit operates through the action of an air operated piston to engage the clutch and compression springs to apply

the brake. The brake unit is actually built into the clutch and is so arranged that when the air pressure in the clutch is

exhausted at the completion of the stroke, compression springs in the clutch apply pressure to a brake disc providing a

positive braking action. This design is important not only because of its ease of operation but because there is no overlap

between the clutch and brake resulting in a more efficient, longer life unit. In the event of electrical or air pressure failure,

the brake will automatically be applied. There is no adjustment or maintenance required throughout the life of the friction

material for either the clutch or the brake.

The clutch is operated at 80 psi of air pressure and is engaged by an electrically controlled three-way solenoid valve.

This solenoid valve is operated through the foot switch for either one complete stroke or for jogging the slide. A limit

switch (Figure 30) is operated by a cam on the eccentric shaft. This limit switch de-energizes the solenoid valve at the end

of the stroke releasing the clutch and allowing the spring operated disc brake to stop the movement of the slide in its top

position. Stopping position of the ram can be adjusted by advancing or retarding this cam. The friction material for the

clutch should be replaced when it has worn to a thickness of 1/2" on Series 0300, 0400, 0600, 0800 and 1000; 1/4" on

Series 0200. A new brake plate (it comes complete with the lining bonded to it) should be installed when the brake plate

assembly has worn to a thickness of 1/2" on all series.

To replace either the clutch plate or the brake plate, proceed in the following manner:

(1)

Remove air supply line "A", Figure 20.

(5) The entire clutch and brake assembly can now

be slipped off of the shaft as shown in Figure 31.

(2)

Remove cylinder air lines "B" and "C".

(6) Remove the four socket head bolts "E", "F' "G"

(3) Remove lock nut "D". In order to do this, an ear

and "H" (Figure 20). These bolts are long enough to

on the lock washer under the nut must be bent open.

completely release all compression on the brake springs

before they are removed; therefore, no danger is

(4) Remove brake bracket bolts "r' and "J" and

incurred in removing these bolts. The unit can now be

remove the bracket.

disassembled as shown in Figure 20.

When the clutch and brake plates have been replaced, reverse the procedure outlined above for reassembly. Always

make sure you thoroughly clean and check the unit for wear whenever it is disassembled.

1. CYLINDER

5.

BRAKE SPRINGS

2. BRAKE PLATE

6.

CLUTCH PLATE

3. PISTON PACKING

7

END PLATE

4. PISTON

8

DRIVING RING

Figure 20. Combination Air Clutch and Spring Brake.

21