TM 9-4110-255-14

Table 4-1. Unit Preventive Maintenance Checks and Services for Model F5000RD - Continued

Location

Item No.

Interval

Procedure

Not Fully Mission Capable If:

Item to

Check/

Service

33

Semi-

Heat

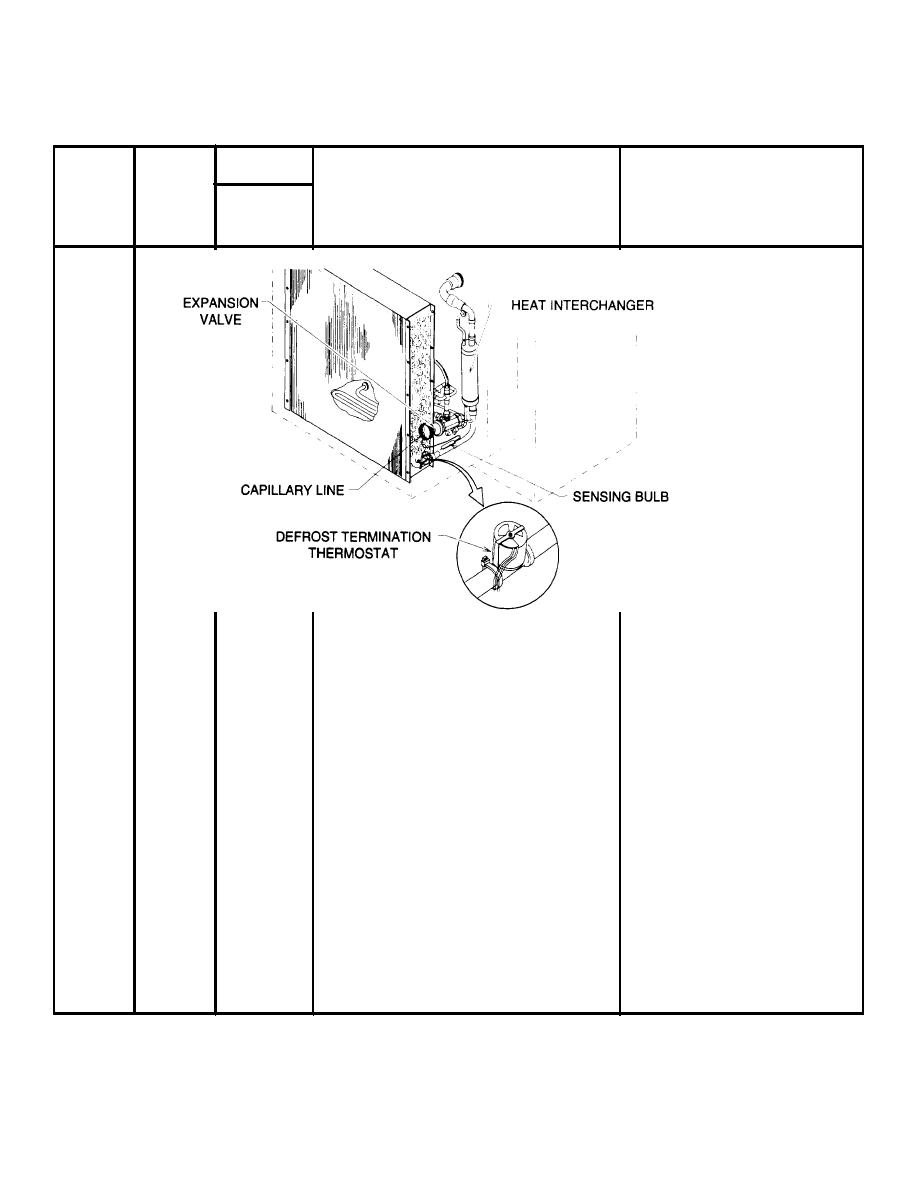

Inspect the heat interchanger for dents or

Heat interchanger is

Annually

Interchanger

evidence of refrigerant leak. If damaged or dented or evidence of leak

evidence of leaking found, notify direct support

is found.

maintenance to replace it.

34

Semi-

Expansion

a.

Inspect the expansion valve for evidence of

Evidence of leak is found,

Annually

Valve

refrigerant leak. If evidence of leak is found,

sensing bulb is loose on

notify direct support maintenance to replace

tubing, or capillary line is

it. kinked or broken.

b.

Inspect the sensing bulb capillary line for

cracks, kinks, or breaks. If damaged, notify

direct support maintenance to replace the

expansion valve.

c.

Check that the sensing bulb mounting

hardware is secure and the bulb is in contact

with the tubing. Tighten the mounting

hardware if loose.

4-27