TM 9-4120-370-14

TO 35E9-229-1

Preliminary procedure:

Remove lower front panel, (See para 4-25.)

a.

Test

(1) Check to be sure power has been disconnected.

NOTE

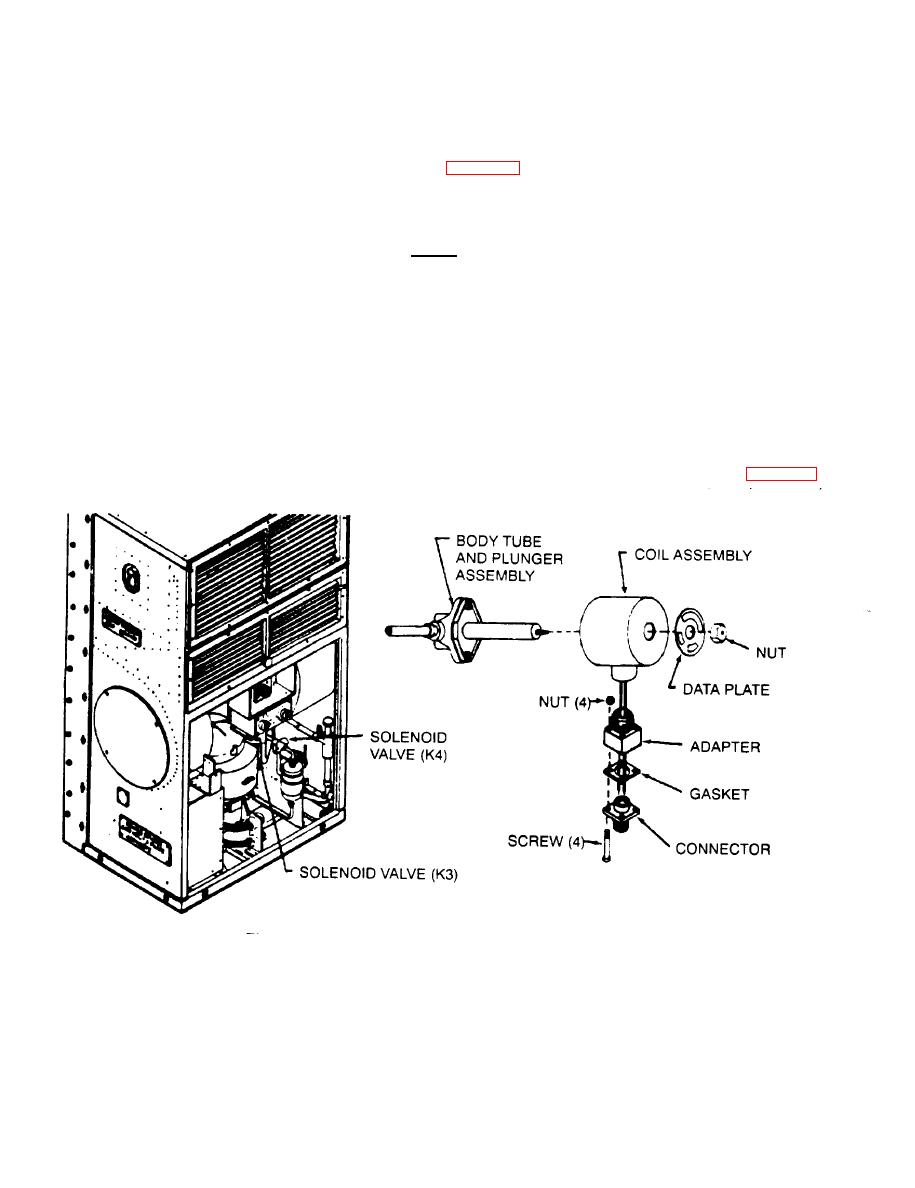

The following basic instructions apply to both the equalizing solenoid valve (K4) and the

liquid line solenoid valve (K3).

(2) Disconnect wiring harness connector (P6) from connector (J6) on solenoid valve (K3) or connector (P5)

from connector (J5) on solenoid valve (K4).

(3) Use a multimeter set on lowest OHMS scale to check for continuity between contacts A and Bin solenoid

valve connector, If continuity is not found, coIl is open and must be replaced.

(4) Use multimeterto check for continuity between each contact in solenoid valve connector and coil casing.

If continuity is found between either contact and case, the coil is grounded and should be replaced.

(5) If continuity checks are satisfactory, apply 24 volts dc from an external power supply across contacts A

and B in solenoid valve connector, and listen for a sharp click when the valve changes position, If a click

is not heard, internal valve problems are Indicated and entire valve should be replaced. (Go to para 526.)