TM 9-4120-370-14

TO 35E9-229-1

5-26. SOLENOID VALVES (K3 AND K4) - Continued.

(8) Leak test all newly connected joints and those in the repair area. (See para 5-10.)

(9) Evacuate and charge the refrigerant system (See para 5-11 and 5-1 2.)

Followon procedure:

Install lower front panel. (See para 425.)

Remove the lower front panel. (See para 425.)

Preliminary procedure:

Inspection

a.

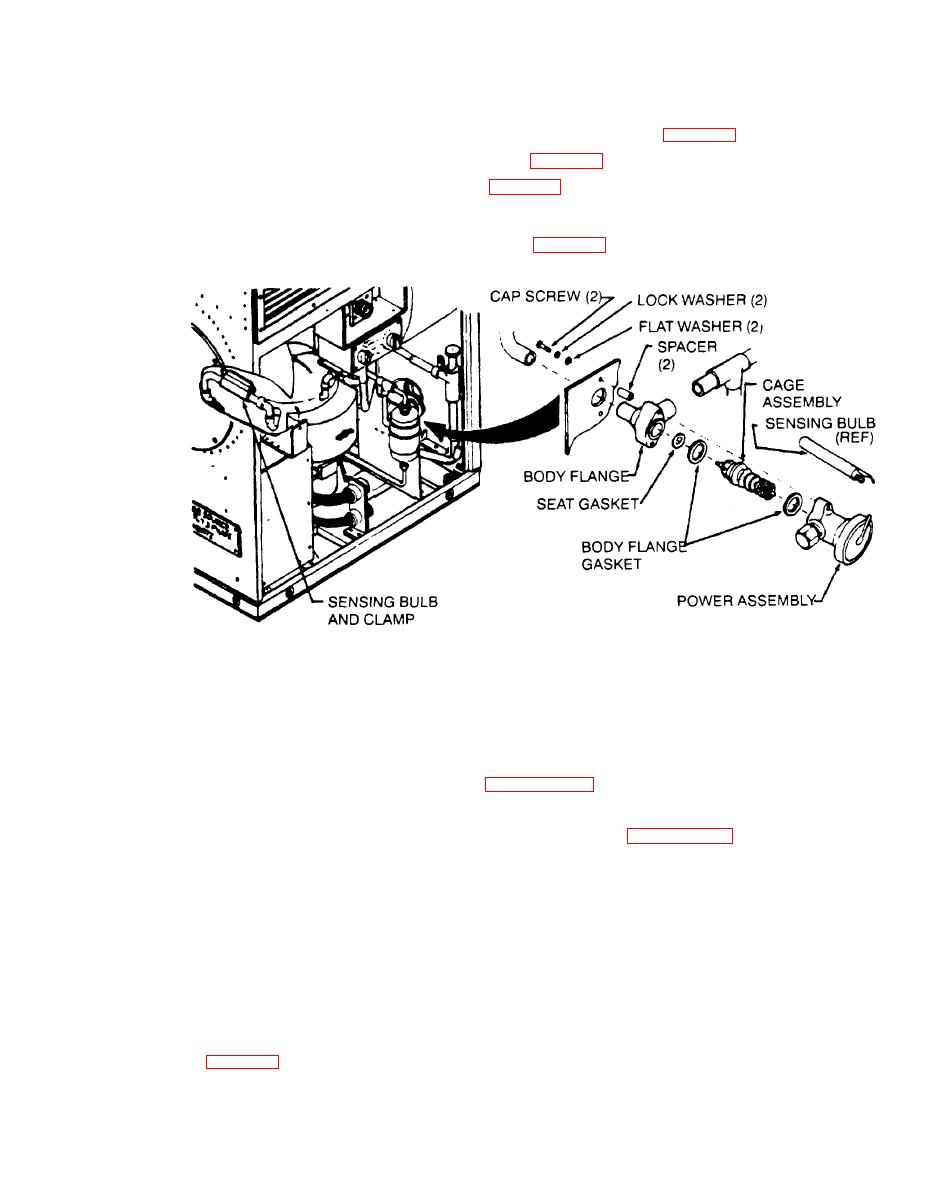

(1) Inspector evidence of leaks, kinked, or otherwise damaged capillary line, and loose or missing mounting

hardware.

(2) Check thermal bulb to see that it is securely clamped to the suction line.

(3) If a leak is suspected or indicated, test per paragraph 5-10.

Test

b.

Perform a refrigerant pressure check on unit in accordance with paragraph 513. Leave gages or service

(1)

manifold attached.

(2)

Unwrap insulation from compressor suction line so that sensing bulb and an adjacent section of the line

is exposed.

Anach an accurate thermometer to an exposed surface of suction line adjacent to the sensing bulb; use

(3)

a small gob of thermal mastic, if available, to improve conductivity.

(4)

Check that service valve and gage connection to low (suction) sides are open. Note pressure indicated on

gage and temperature indicated on thermometer.

Set the Temperature control thermostat knob to full INCREASE (clockwise). Start the air conditioner in

(5)

for at least 20 minutes. If pressure is not within above limits, test operation of pressure regulating valve