A

B

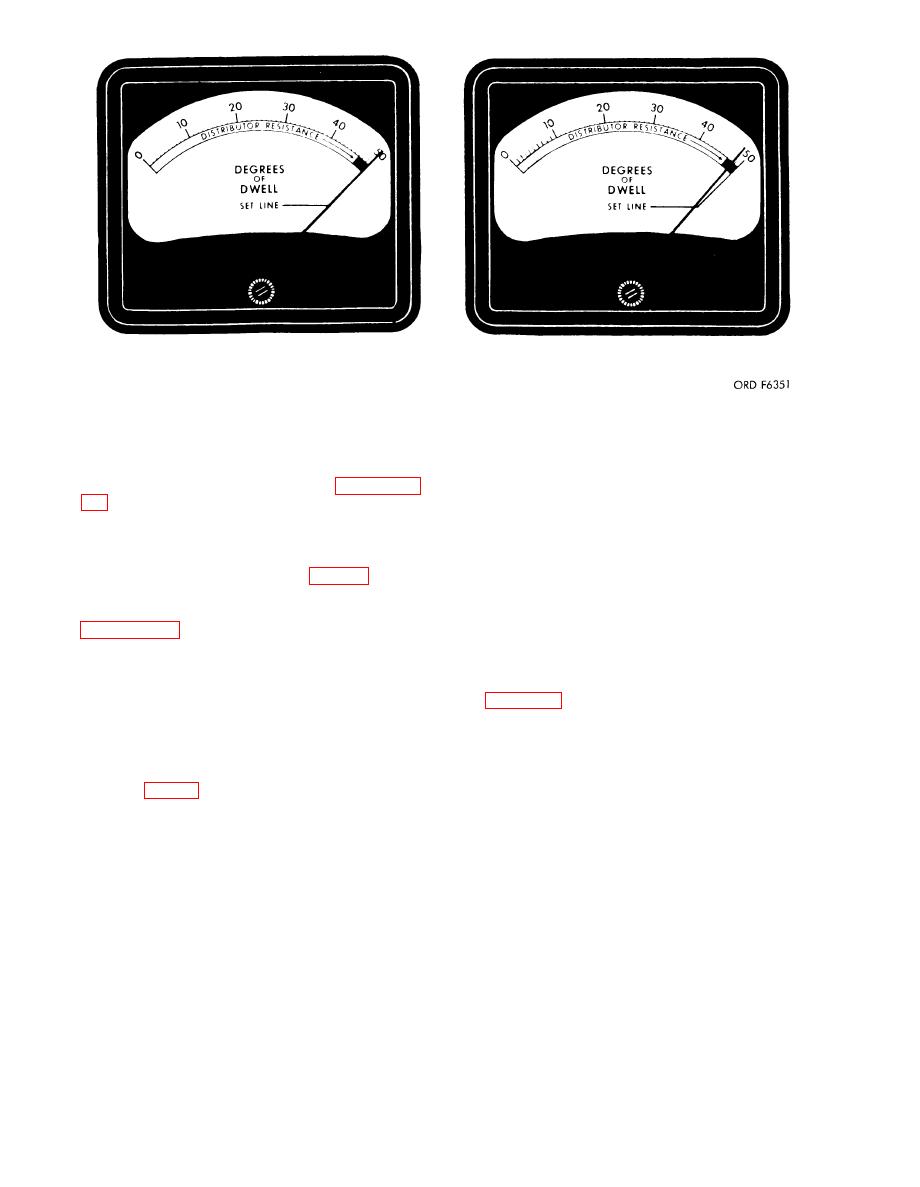

Figure 6. Dwell meter resistance readings.

e. Adjust the speed control handwheel

starting, operating, and stopping the dis-

(15) until the pointer reads 200 rpm on

tributor tester are contained in paragraph

the tachometer indicator (3), read the cam

29 below.

angle degrees on the dwell meter, and

check this reading against the cam angle

29. Cam Angle Test

of the distributor as specified by the ap-

plicable TM or by the manufacturer of the

Mount the distributor (par. 27). Zero

distributor.

t h e dwell meter (2), tachometer indicator

f. Turn the speed range selector (18)

(3), and vacuum gage (1), as prescribed in

to 0-2500 rpm and increase the speed to

2000 rpm. The reading on the dwell meter

in the "off" position.

(2) should be within two degrees of that

b. Set the cam angle selector (19) to the

obtained in e above.

"8 CYL" position and connect the distrib-

utor lead (7) to the distributor and the

hook-up for distributors with vacuum con-

ground lead (10) to the ground terminal (8)

trols, single condenser, two condensers

on the distributor clamp (26). If there is

with double breaker points, and distribu-

no reading on the dwell meter (2), rotate

tors with double lead condensers. On dis-

the distributor shaft until the distributor

tributors with double breaker points the

points (fig. 7) are closed and the dwell

meter shows a reading. Aline the meter

cam angle on each set of points are checked

separately and each must show the same

pointer with the "set line" mark on the

reading on the dwell meter. To block one

meter scale using the cam angle adjust-

ment (20).

set of breaker points open while testing

the other set, place a piece of fiber or any

c. Turn the cam angle selector to either

nonconducting material between the points.

the "4 CYL", "6 CYL", or "8 CYL" posi-

h. Turn the speed control handwheel (15)

tion, whichever corresponds with the num-

ber of lobes on the distributor cam.

clockwise and reduce the speed to its low-

est point on the 0-2500 range, switch the

d. Set the motor switch (17), to the di-

rection in which the distributor shaft is

speed range selector to 0-500 range and

driven on the vehicle, and turn the speed

adjust the distributor speed to 200 rpm

with the distributor still connected, and

range selector (18) to the 0-500 range.

12