materiel are listed in appendix I. For a listing

m e d i a t e l y reported in accordance with the

of all forms, refer to DA Pam 310-2. For in-

applicable instructions in cited regulation.

structions on use of these forms, refer to TM

d. Field Reports of Accidents. T h e r e p o r t s

38-750.

necessary to comply with the requirements of

c. Equipment Improvement Recommendation.

A r m y safety program are prescribed in detail

Any deficiencies detected in the equipment cov-

i n AR 385-40. These reports are references

e r e d herein which occur under the circum-

whenever accidents involving injury to person-

stances indicated in AR 750-5, should be im-

nel or damage to materiel occur.

DESCRIPTION AND DATA

Section II.

plied with the test stand to provide a means to

4. Description

keep the storage batteries of the internal bat-

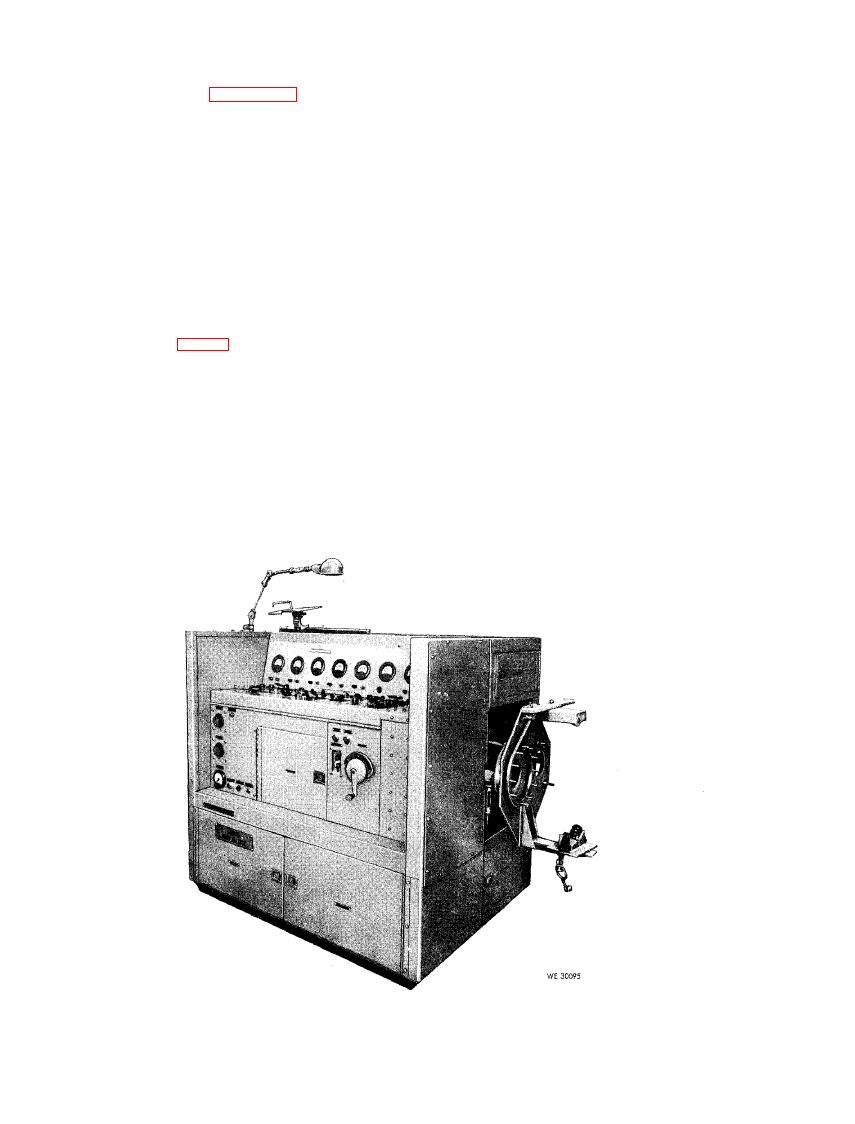

The test stand (figs. 1, 2, 3, and 4) is an elec-

tery circuit in a fully charged condition (this

t r i c a l l y operated device having a 10 to 50 volt,

battery charging unit is not supplied with the

50 to 500 ampere, dc testing range and a 25 to

type II, part number 7336 (4910-316-5252) test

50 volt, 100 to 400 ampere, ac testing range.

stand). Basically its physical construction con-

Its electrical construction consists of a multiple

s i s t s of a steel cabinet containing a control

of circuits which are utilized to test direct-drive

panel; 22-horsepower, 220/440-volt, 60-

o r pulley-driven generators, generator regu-

c y c l e , 3-phase varidrive motor with a 800 to

l a t o r s , generator control boxes, ac/dc systems

1 1 , 0 0 0 - r e v o l u t i o n per minute dual-head take-

(alternator, rectifier, and generator regulator),

off assembly; load bank with a blower both of

and starters (cranking motors). A built-in

manually operated battery charging unit is sup-

which are enclosed within a sheet metal hous-

Figure 1.

Test stand (model AGARTS, type II, part number 7336-1) (4910-767-0218) - right front view.