WARNING

GROUNDING

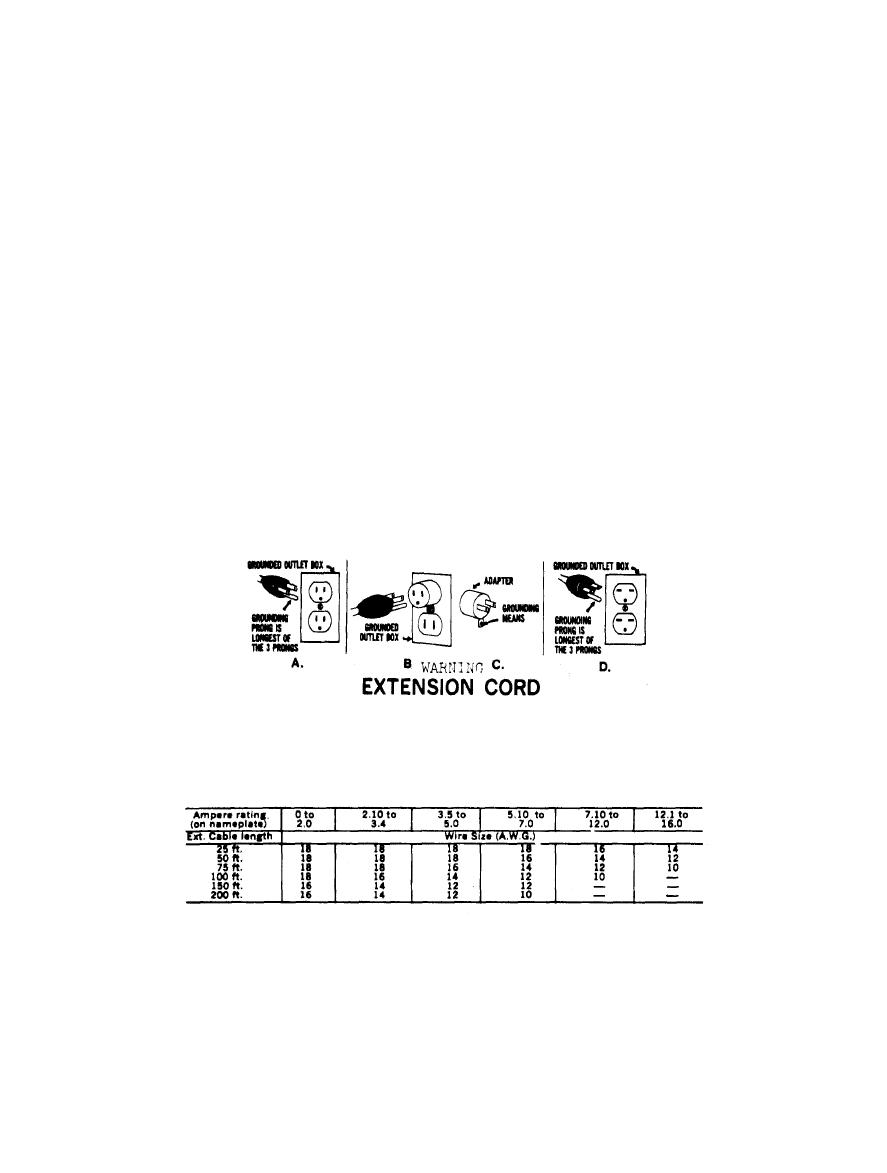

This tool should be grounded while in use to protect the operator from electric shock.

The tool is equipped with an approved three-conductor cord and three-prong ground-

ing type plug to fit the proper grounding type receptacle. The green (or green and

yellow) conductor in the cord is the grounding wire. Never connect the green (or

green and yellow) wire to a live terminal. If your unit is for use on less than 150

volts, it has a plug like that shown in Figure A. If it is for use on 150 to 250 volts,

it has a plug like that shown in Figure D. An adapter, Figures B and C, is available

for connecting Figure A plugs to two-prong receptacles. The green-colored rigid ear,

lug, etc., must be connected to a permanent ground such as a properly grounded

outlet box. No adapter is available for a plug as shown in Figure D.

It`s recommended that you NEVER disassemble the tool or try to do any rewiring in the

electrical system.

Should you be determined to make a repair

yourself, remember that the green colored wire is the grounding wire. Never

connect this green wire to a live terminal. If you replace the plug on the power

cord, be sure to connect the green wire only to the grounding (longest) prong on a

3-prong plug.

If you use an extension cord, be sure that it is a 3-conductor, grounding type cord.

Grounding must be continuous from the tool plug to the grounded receptacle.

When using the tool at a considerable distance from power source, a 3-conductor,

grounding-type extension cord of adequate size must be used for safety, and to

prevent loss of power and overheating. Use the table below to determine minimum

wire size required.

Use only three wire extension cords which have three-prong grounding-type plugs and

three-pole receptacles which accept the tool's plug. Replace or repair damaged cords.

LUBRICATION

The tool iS properly lubricated at the factory and is ready for use. Tools should

be relubricated regularly (UNPLUG TOOL first) every sixty days to six months,

depending on usage. (Tools used constantly on production or heavy-duty jobs and

tools exposed to heat may require more frequent lubrication.) This lubrication

should only be attempted by trained power tool repairmen.

3