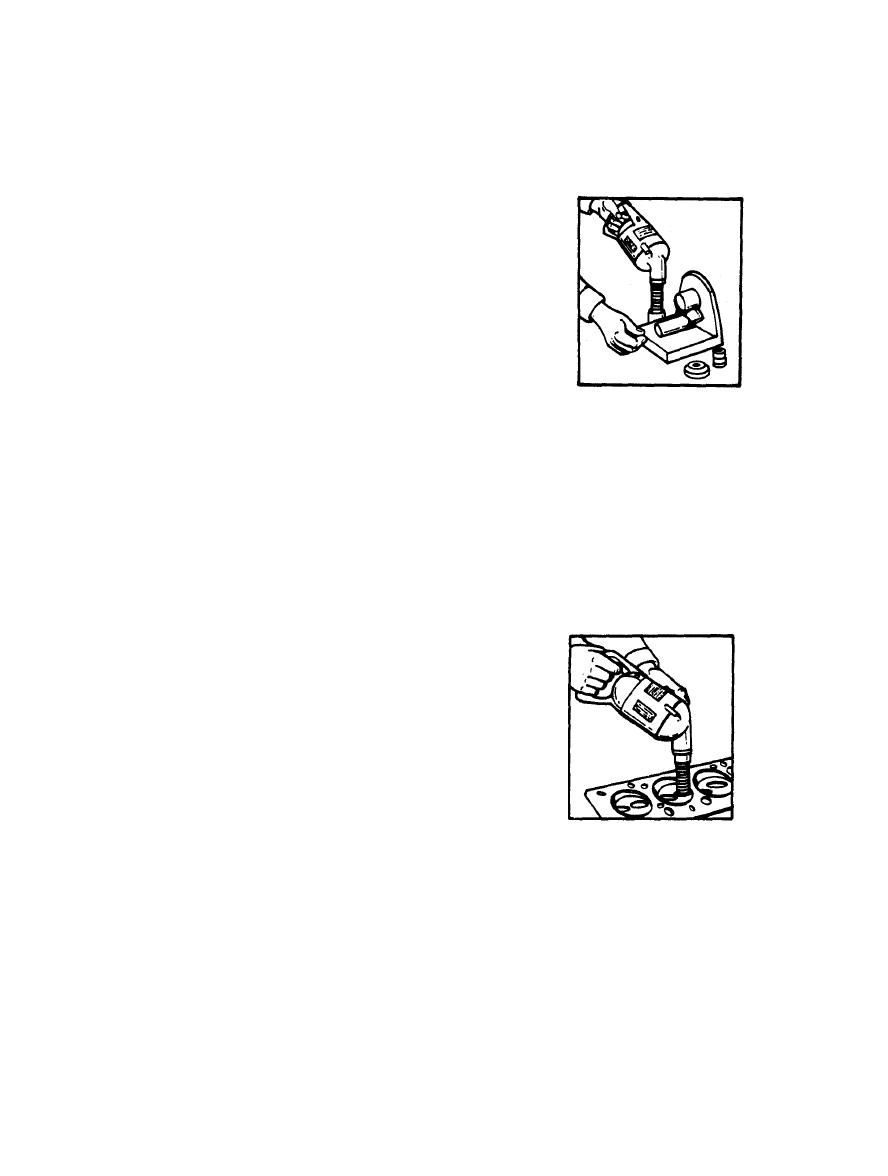

DRESSING THE STONE-

Select stone

in correct size. Screw the stone tightly against collar

of the sleeve. Adjust the arm of the dressing stand

so the angle dressed on the stone corresponds to

the angle ground on the valve face. Wipe dressing

stand mandrel free of dust and grit, and put one or

two drops of light oil in the stone sleeve bushing.

Place the stone and sleeve over the mandrel and

adjust the diamond to contact the stone by means

of the knurled head on the outer end of the diamond

nib. Lock diamond nib in place with handle while

dressing stones. Use the

unit to drive

the stone and sleeve. Put just enough pressure on the driving unit to over-

come its vibrating action. Too much pressure causes unnecessary friction.

With the stone revolving, take a light cut by moving the diamond slowly

across the stone by means of the feed lever. Turn the knurled head on the

diamond slightly to take additional cut. Repeat until the diamond cuts the

entire face of the stone, producing a true angle and a fresh cutting surface.

Every new stone should be dressed for angle accuracy before being used,

and should be redressed whenever it is remounted on a stone sleeve. To

dress stone accurately for minimum stone run-out, stand must be clamped to

a workbench.

G R I N D I N G THE VALVE SEAT-

After the pilot has been inserted and the stone and

sleeve is in place insert hex-ball spindle into the

stone sleeve socket and grind for a few seconds

(slightly longer for steel inserts). Stellite seats require

several minutes of grinding depending on eccentri-

city and wear. While grinding support driver lightly

to allow its vibrating mechanism to operate freely. The

vibrating principle is important and pressure on the

action, caus-

driver would overcome the

ing the stone to load rapidly.

Narrow with a 15 stone any badly worn seat

made too wide by the grindina (prevents the valve

seat surface from becoming wider than the valve face).

The

valve seat grinding stone gives an accu-

rate, mirror-smooth face on every job. Lapping valves in their seats is

unnecessary if precision equipment is correctly used and valve seat and

valve face test true with prussian blue or a valve seat indicator.

7