VALVE SEAT GRINDING OPERATIONS

WARNING: Always wear eye protection.

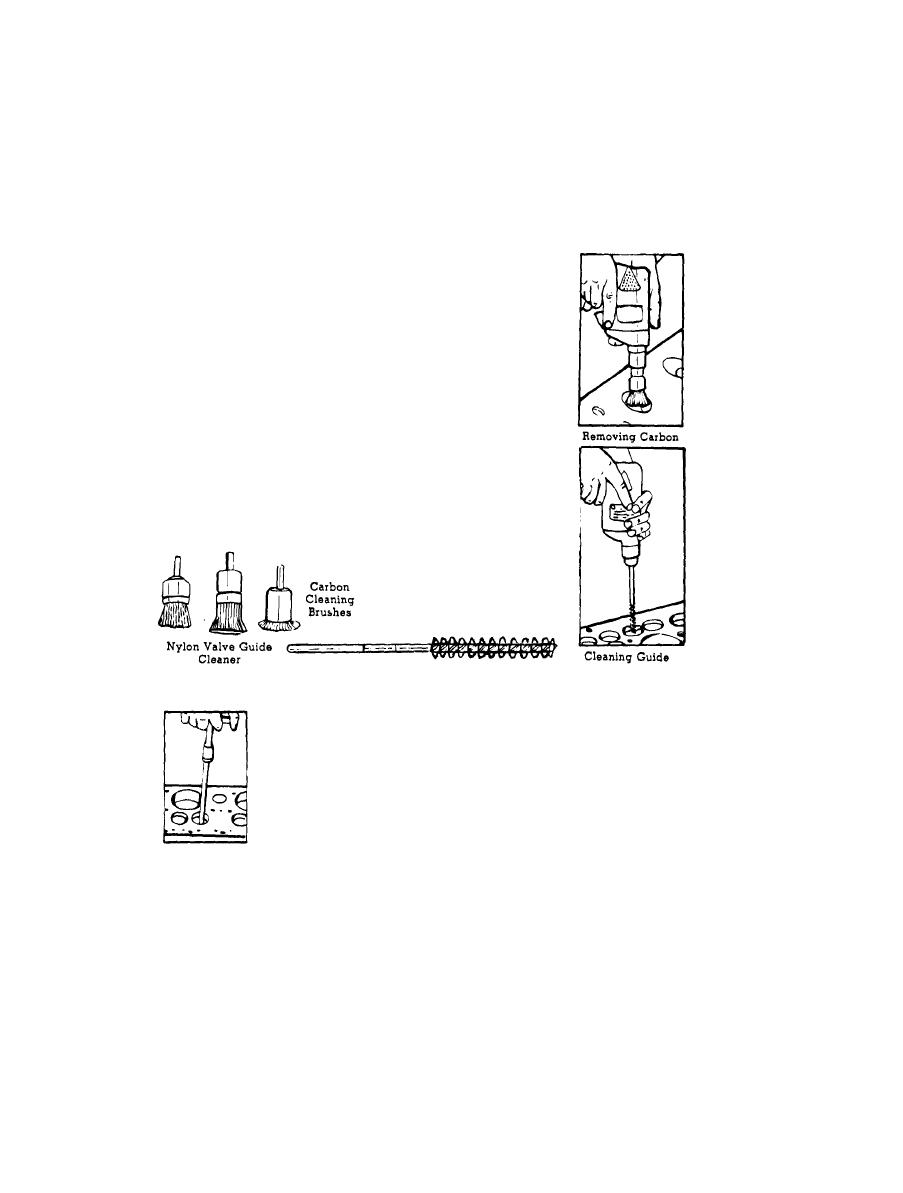

CARBON CLEANING-

Use a " Drill for

driving wire carbon cleaning brushes in removing carbon

from the engine block and cylinder heads. The bright,

burnished surface produced will retard carbon accumula-

tion in the completed job. Kerosene will help to remove

very hard carbon. Use proper brushes on aluminum heads

to avoid scoring. After carbon cleaning thoroughly remove

all loose carbon dust.

To sharpen carbon brushes, grind the wire ends square

by holding the brush in an electric drill with the brush

revolving against a running grinding wheel.

Valve guides require very careful cleaning. Carbon

left in the guide will deflect the pilot, resulting in inaccu-

rate work. With " drill, and correct size cleaner, use

the following procedure. 1 . Insert cleaner in guide

before starting drill. 2. For better cleaning, move cleaner

up and down in guide several times - be sure portion of

bristles is kept within the valves guides. 3. Wipe bristles

with clean cloth after clean-

i n g each guide. 4 . The

b r i s t l e s will not be ad-

versely affected by oil or

gasoline.

INSERTING THE PILOT-

After the proper size pilot for the valve

guide has been selected, the tapered sleeve on this pilot

should be run out on its thread as far as possible. Then

insert this pilot until its upper taper stops on the top of

the valve guide. Turn the pilot clockwise with a pilot pin

or pilot wrench to draw the split sleeve against the pilot's

lower taper, thus expanding the split sleeve and locking

the pilot tightly in the guide. Do not overtighten - a firm

fit is desirable. To remove the pilot, turn it once or twice

counterclockwise and pull out.

INSTALLING STONE and SLEEVE on PILOT-

Apply thin film of oil to the pilot - slide the stone sleeve down on the pilot

shank until the storm rests on the valve seat.

Use two stone sleeves to facilitate seat grinding. One sleeve may carry

stone, another a 15

reconditioning valve seat grinding

a

narrowing stone. This procedure eliminates the delay

involved in changing stones on one sleeve for once the pilot is placed in a

valve guide both the finishing and narrowing cuts are usually made to com-

plete that particular valve seat before removing the pilot.

6