TM 9-4910-679-14&P

MEASURING TAPPET CLEARANCE- (CONTINUED)

the block when depth gage is used. Turn engine until the tappet being gaged is at lowest point. With proper bushing and

beveled head fitted snugly in place, loosen knurled nut and slide stem (K) down to contact tappet. Clamp tightly in this

position with knurled nut. Remove the Depth Gage from engine and place in V-way of Attachment, with stem close to flat

grinding face of wheel. Clamp stem securely in place with quick-clamp (D). Adjust V-stop (E) to contact beveled head and

lock V-stop with knurled screw (H). Adjust Micrometer Feed Nut until stem just touches grinding face of wheel. Move

calibrated dial to O setting and the dial will move independently of the knurled nut at the end of the micrometer spindle. It

is now possible to grind definite clearances on the valve stem by turning the knurled nut. The dial will move with the

knurled nut and each calibration is 0.001". Do not grind end of Depth Gage.

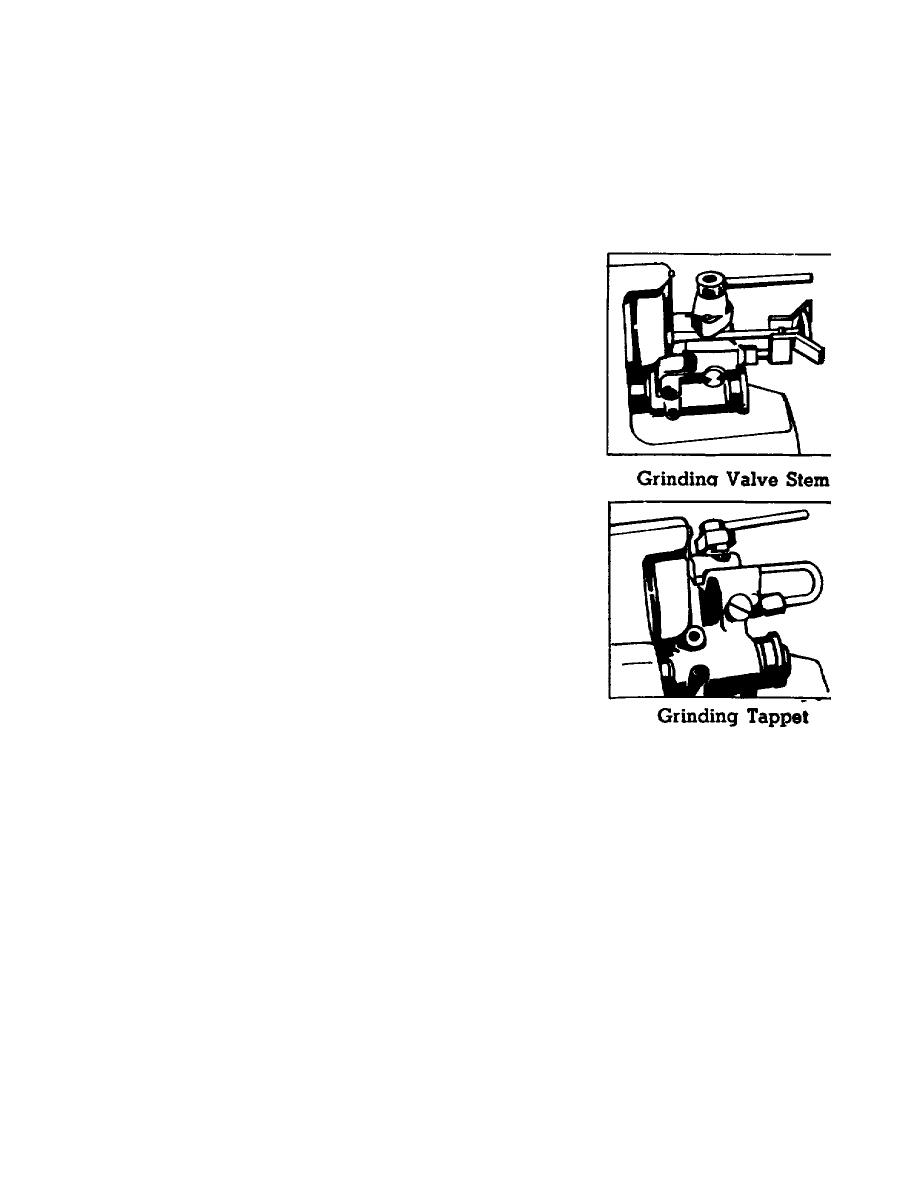

GRINDING the VALVE STEM-

Swing the V-block Arm toward you, free of the wheel, and remove the

Depth Gage by loosening quick- clamp (D). Do not change setting of V-Stop (E).

Insert valve stem in V-way, with Valve head firmly seated in V-stop, and clamp in

position with quick-clamp. Turn back the Micrometer Feed Nut until valve stem

just clears grinding wheel. Start the wheel motor. Advance the micrometer feed

not more than 0.004"and rock the V-Block Arm slowly toward and across the flat

grinding face. Continue to rock back and forth until the wheel stops grinding;

swing the attachment toward you free of the wheel, advance the feed

another0.004"and again rock the attachment back and forth until the wheel stops

grinding. Repeat this operation, advancing the feed slowly until you reach the

reading noted above as the grinding limit. This will give you the correct tapped

clearance, and the valve stem end will be polished and squared.

It is important to dress the flat face of the grinding wheel frequently with the

diamond point, to ensure fast, clean grinding and a square valve stem-end If the

wheel is removed from spindle, it should be dressed again when replaced, to

ensure proper alinement.

As a final finishing touch to any job all valve stem ends should be squared

and polished--even on engines with adjustable tappets. This is easily and quickly

done on the Micrometer Attachment, using the V-way to position the valve stem,

but not using either the V-stop or the Micrometer Feed. A very light grind is

usually sufficient to square the stem.

SQUARING and TRUING TAPPETS-

Clamp tappets in the V-way of the attachment. Feed tappet up to contact the flat side of wheel. Swing attachment toward

you, free of wheel and start wheel motor. Advance micrometer feed only 0.002"or0.003"and swing back and forth across

flat face of wheel until the tappet end is square and polished. By using stop provided, tappets can be ground to the same

length if desired.

10