MAINTENANCE INSTRUCTIONS

Section I. OPERATOR'S MAINTENANCE

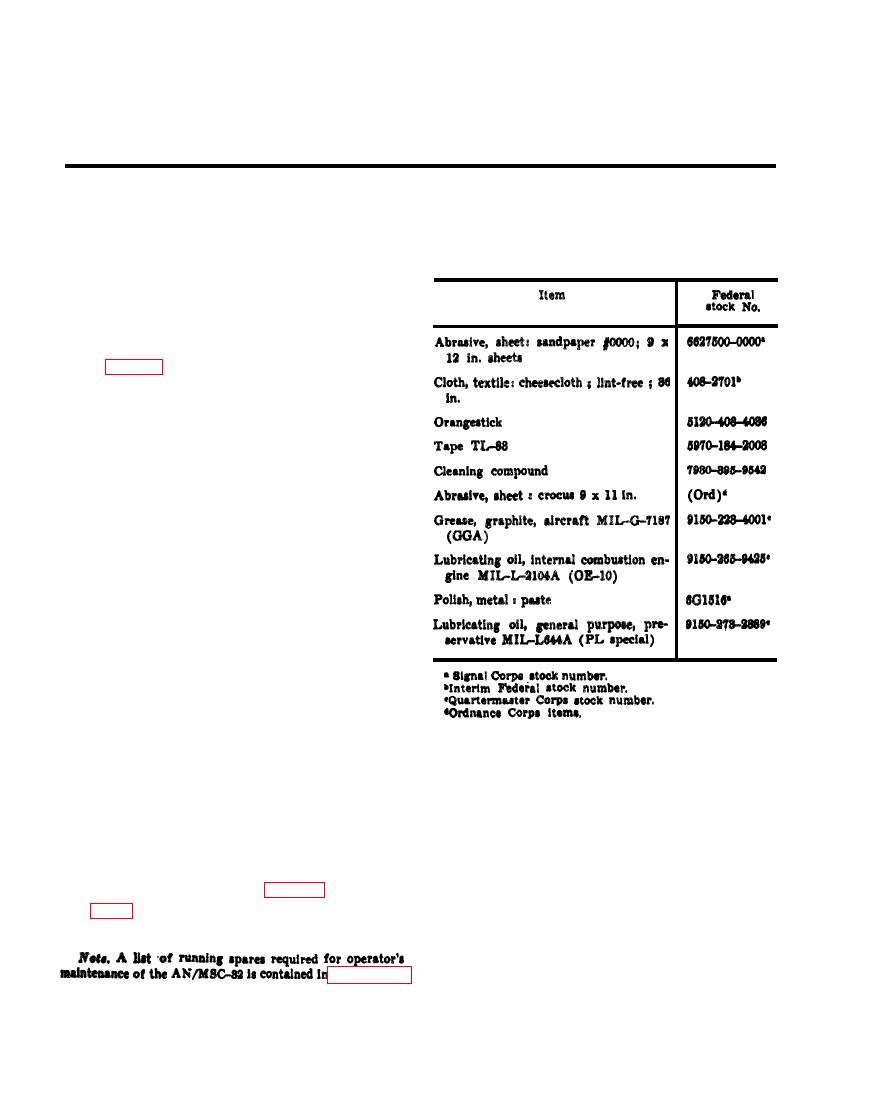

b. Materials.

Clean and inspect all component of the AN/

MSC-32 regularly. Detailed maintenance pro-

cedures pertaining to the major components

are covered in the appropriate technical man-

uals (appx I).

a. Use a clean, dry, lint-free cloth or brush

for dusting.

b. For cleaning, if necessary, moisten the

cloth or brush with Cleaning compound (FSN

7 9 3 0 - 3 9 5 - 9 5 4 2 ) ; after cleaning, wipe dry

with a cloth. Do not use cleaning compound

on electrical contacts.

Warning: Cleaning compound is flammable

and its fumes are toxic. Do not use near a

flame; provide adequate ventilation.

c. Dry, compressed air, not exceeding 60

pounds per square inch, may be used to re-

move dust from inaccessible places.

Warning: Compressed air is dangerous and

can cause serious damage to eyes, ears, nose,

and other parts of the body. It also can cause

mechanical damage to the equipment. Do not

use compressed air to dry parts where clean-

ing compound has been applied.

dition of the equipment and spare parts.

b. Remove dirt, dust, grease, and moisture

a. Tools and Test Equipment. The tools and

from the exposed parts.

test equipment required for maintenance of

c. Remove rust, corrosion, fungi, dirt, and

the major components are listed in the ap-

moisture from the binding posts, cable con-

nectors, and receptacles.

plicable technical manuals (appx I). The tool

d. Inspect the field wire connections at the

kit (fig. 2) is required for maintenance of the

binding posts for good contact.

S-184/MSC-32.

e. Inspect the ground rods and ground strap

connections for good contact.

III.

f. Inspect all exposed cables for kinks,