TM 55-1925-285-13&P

OPERATOR, UNIT, AND DIRECT SUPPORT MAINTENANCE

OIL WATER SEPARATOR FOR

INLAND AND COASTAL LARGE TUG (LT)

THEORY OF OPERATION

GENERAL

The Large Tug (LT) utilizes an Oil Water Separator (OWS) to remove oil from bilge water, thus cleansing the bilge

water before it is permitted to be discharged overboard. An Oil Content Monitor (OCM) is used in conjunction with

the OWS to monitor oil levels in the discharge stream from the OWS. The OCM prevents accidental overboard

discharge of oil-contaminated water by sounding an alarm and by redirecting the discharge flow whenever se-

lected discharge oil levels are exceeded. The theory of operation for these two interrelated systems is presented

in the paragraphs below.

OIL WATER SEPARATOR (OWS) THEORY

Operation of this OWS is based on the fact that oil is lighter than water, causing oil droplets to rise through a still

or slowly flowing body of water. This is known as gravity separation. The larger an oil droplet is, the faster it will

rise, and very small droplets may not rise at all. To remove more of the oil as it flows through the OWS, the design

also incorporates coalescing sections, in which small droplets contact each other and form larger ones.

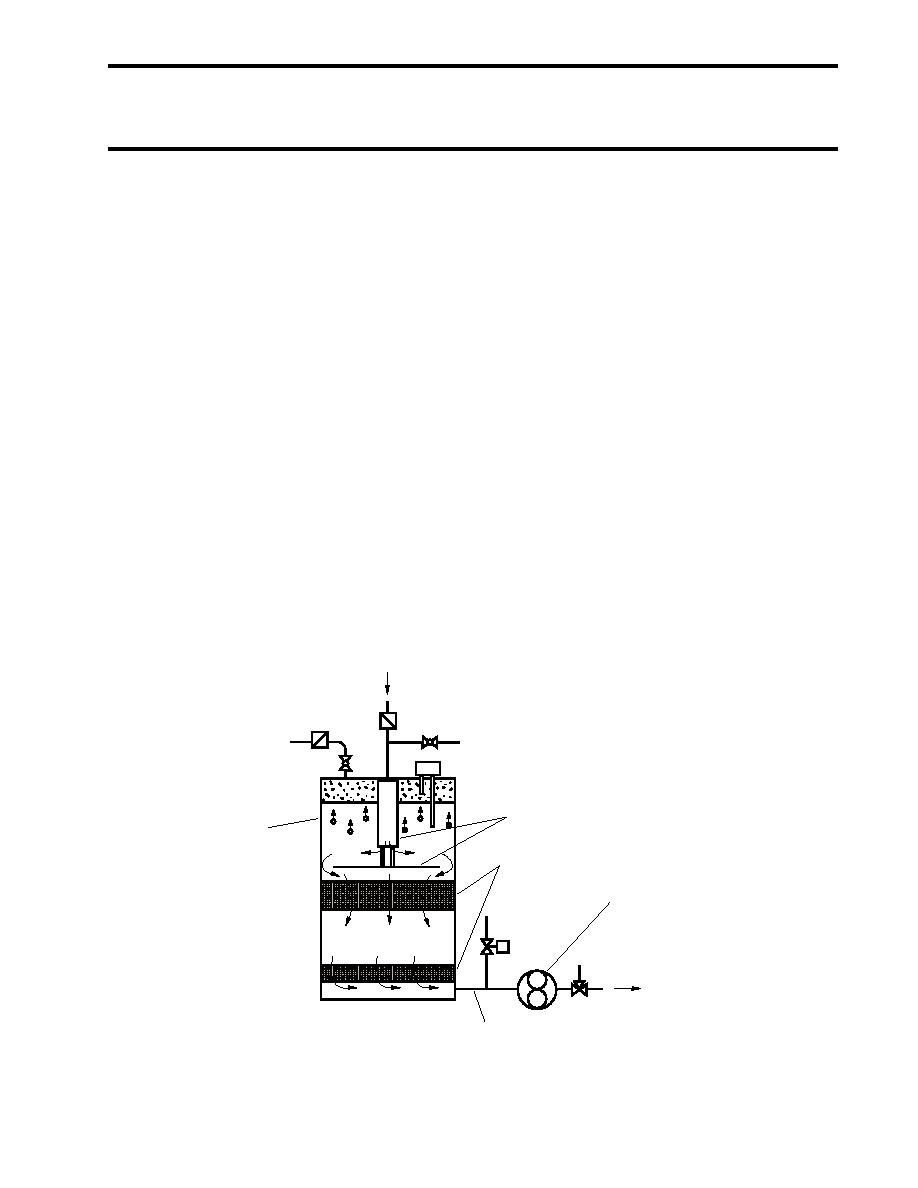

A positive displacement pump (figure 1, item 1), mounted downstream of the OWS tank, draws unprocessed oily

water from the Oily Waste Tank (OWT) into the separator (figure 1, item 2). The separator consists of a single

tank in which several oil-separation zones are created by the inlet weir and baffle arrangement, (figure 1, item 3),

two permanent polypropylene coalescer beds (figure 1, item 4), and the water spaces between them. In this

design, the oil-water separation is accomplished in two stages. The upper zones of the tank promote gravity

separation. The inlet baffle directs the flow of oil droplets away from the upper coalescer bed. This provides an

extended retention time for the oil droplets in the upper portion of the tank, which enables the larger oil particles

to separate and rise to the tank top. The inlet weir separates the oil accumulated in the tank from the inlet flow.

This helps to prevent remixing of the accumulated oil in the tank top during the normal operation and manual

OILY WATER

FROM OWT

OB-13

CLOSED

INTERFACE

OWS-2

SENSOR

OPEN

3

2

4

1

GS-74

CLOSED

CLEAN

WATER

OVERBOARD

OWS-4

OWS

5

PUMP

ON

Figure 1. Normal Processing Mode

0003 00-1