TM 55-1930-208-10

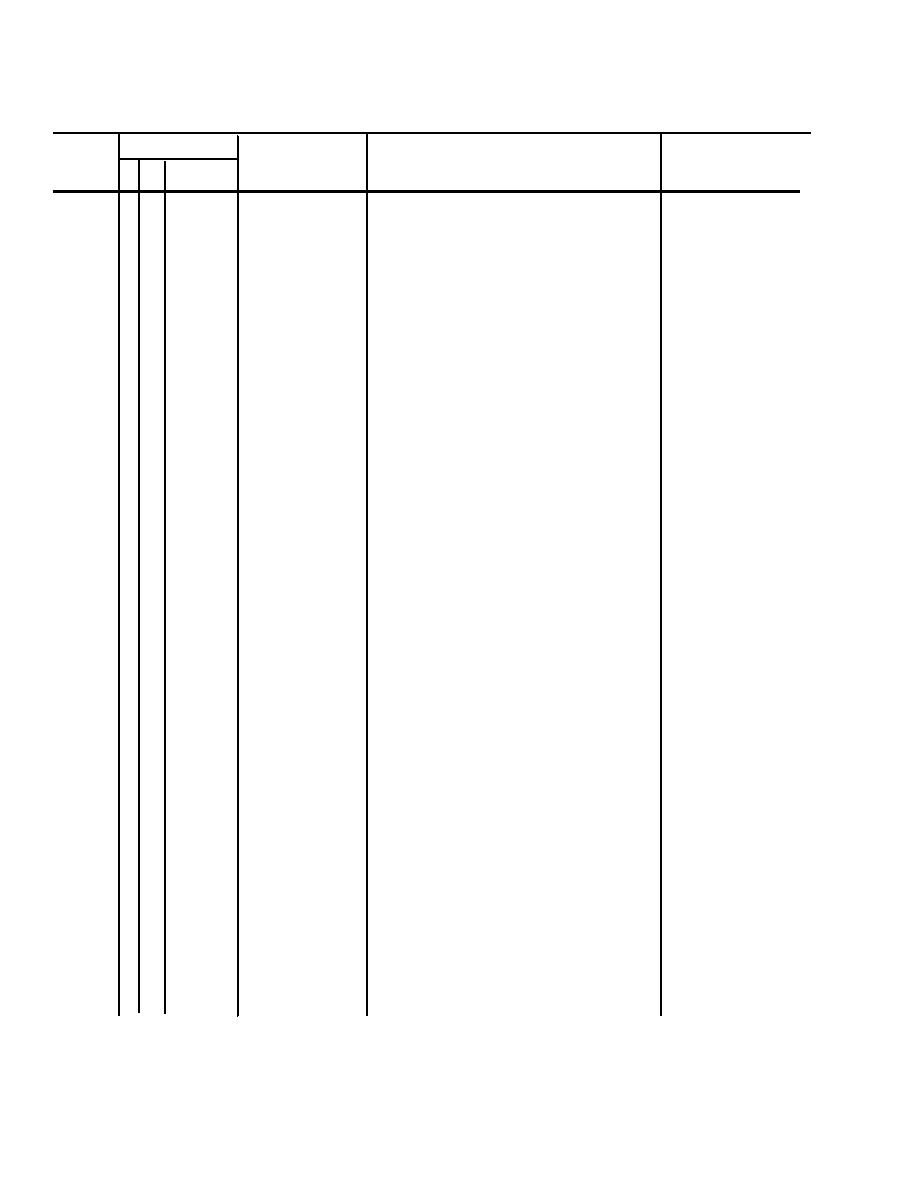

Table 2-4. Operator/Crew Preventive Maintenance Checks and Services (PMCS

INTERVAL

PROCEDURES

EQUIPMNET IS

ITEM

ITEM TO BE

CHECK FOR AND HAVE REPAIRED

NOT READY/

NO

B

D

A

INSPECTED

OR ADJUST AS NECESSARY

AVAILABLE IF:

1

HULL

Inspect for corrosion,

Hull leaks are

leaks, and loose parts.

found.

If corrosion is found,

clean and paint. Tighten

mounting hardware for all

loose parts. If hull

leaks are found notify gen-

eral support maintenance.

2

ULLAGE ASSEM-

Inspect for corrosion.

BLY

Clean and paint areas with

corrosion. Inspect screen

for clogging. Clean if

dirty. Inspect gasket for

damage. Replace a damaged

gasket.

3

FLAME SCREEN

Inspect flame screen for

clogging or damage. Clean

if dirty and replace if

damaged.

4

ENGINE SHUT-

Lift cover. Inspect switch

Engine shutdown

DOWN

mechanism for ease of oper-

does not operate.

ation. Lubricate switch

handle rod. Lower cover.

Inspect the line from switch

to engine and conduit. Re-

place if damaged. Perform

operational test with engine

running at no load.

5

HOUSE, MA-

Inspect for rust or corro-

CHINERY

sion. Inspect for breaks in

framing. Inspect door hard-

ware for damage, rust, or

corrosion. Inspect door

seal gasket. Replace if

damaged. Wire brush and

paint where necessary. No-

tify general support mainte-

nance of breaks in floor or

walls that need welding re-

pairs.

2-7