TM 9-2330-271-14&P

(3) Jack up axle to proper design height from

NOTE

horizontal axle centerline to underside of frame (14

It will take 2 to 6 seconds after

inches plus or minus one-eighth of an inch). Tighten

adjustment of nylon block before air

nuts (25) with axle in proper height position to a torque of

starts to flow through valve. This is

150 lb-ft.

caused by the built-in time delay.

(4) Install cap screws (5), flat washers (27)

(7) Adjust valve by loosening adjustment lock

and nuts (28) and tighten to a torque of 200 lb-ft. (table

nut and carefully moving nylon block (fig. 4-41) until

dimension of 14 inches, plus or minus one-eighth of an

inch, is reached. Tighten adjustment lock nut.

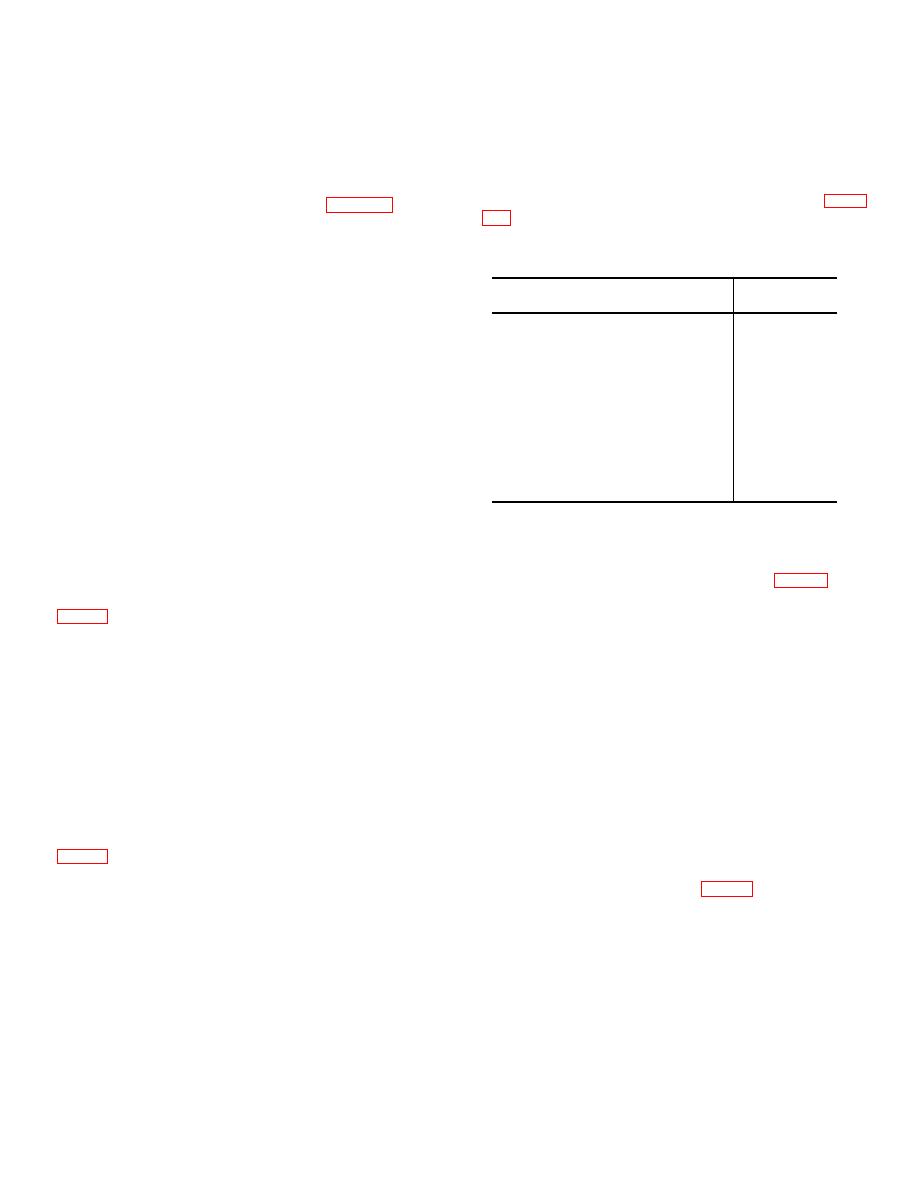

Table 4-3. Torque Limits

(8) Disconnect linkage and let springs deflate

about half way. Reconnect linkage and allow springs to

Nut size

Torque limits

inflate. When valve shuts off, check height dimension

(lb-ft)

again.

Air Ride Suspension and Air

(9) Repeat steps (6), (7), and (8) above until

Mounted Kingpin

proper 14 inches, plus or minus one-eighth of an inch,

1/2-inch

25 lb-ft

dimension is reached.

5/8-inch

140 lb-ft

(10) Disconnect the valve adjusted in previous

3/4-inch

200 lb-ft

steps and move actuating arm to a vertical down position

3/4-inch (air spring only)

20 lb-ft

to deflate springs.

7/8-inch

300 lb-ft

(11) Repeat steps (5) through (10) above with

1-inch

450 lb-ft

the opposite height control valve.

1-1/8 inch

700 lb-ft

(12) Connect both actuating arms with their

1-1/4 inch

900 lb-ft

respective linkage. When springs are fully inflated and

Piston nut inside air spring

50 lb-ft

valves shut off, check height dimension. Both valves

should be synchronized.

(5) Reconnect linkage to height control valve.

(6) Install wheels and remove blocking and

4-57.

Replacement of Air Suspension System

jacking equipment.

Components

c. Replacement of Torsion Bar Only (fig. 51).

(1) Block up semitrailer to remove all weight

a. Removal of Rubber Bushing and Torsion Bar

from suspension.

(2) Remove front or rear wheels as

(1) Remove weight from suspension by

applicable.

blocking up semitrailer and jacking up axle. Remove

(3) Grind a one-fourth inch by 45 degree

front or rear wheels as applicable.

chamfer on one end of new torsion bar.

(2) Disconnect linkage from height control

(4) Remove outer nuts (28), flat washers (27),

valves and depress actuating arms to exhaust air

and cap screws (5). Loosen inner nuts (28).

pressure from air springs.

(5) Place chamfered end of new torsion bar

(3) Remove nuts (28), flat washers (27) and

against end of old torsion bar (32) and drive out old

cap screws (5) and loosen frame bracket nuts (25).

torsion bar. Make sure notch in new torsion bar is

Drive torsion bar (32) completely out of assembly using

positioned to receive cap screw in outer torsion bar

care not to mushroom bar end.

clamp of left hand equalizing arm (16).

(4) Carefully let both equalizing arms (16)

(6) Install cap screws (5), flat washers (27),

down away from frame brackets. Push out bushing (31).

and nuts (28); tighten all nuts to a torque of 150 lb-ft.

b. Installation of Rubber Bushing and Torsion Bar

(7) Install wheels and remove blocking and

jacking equipment.

(1) Slip in new bushing (31) and rotate, as

d. Removal of Air Spring (fig. 51).

near as possible, to operating position. Place spacers

(1) Block up semitrailer to remove all weight

(24) on ends of bushing and move equalizing arms (16)

from suspension.

back to their proper positions relative to frame brackets

(2) Disconnect linkage from height control

(29). Line up bushing square holes with arm square

valve supplying faulty air spring and exhaust pressurized

holes to receive torsion bar.

air by moving actuating arm down.

(2) Insert torsion bar (32) through arm ends

(3) Disconnect air line (8) from top of air

and bushings. Make sure that notch in bar is alined to

spring (15). Remove upper mounting nuts (11 and 12),

receive offset cap screw (5).

lock washers (10 and 13), and flat washer (9). Remove

lower mounting cap screws (17) and lock washers (13).

4-62