TM 9-2330-271-14&P

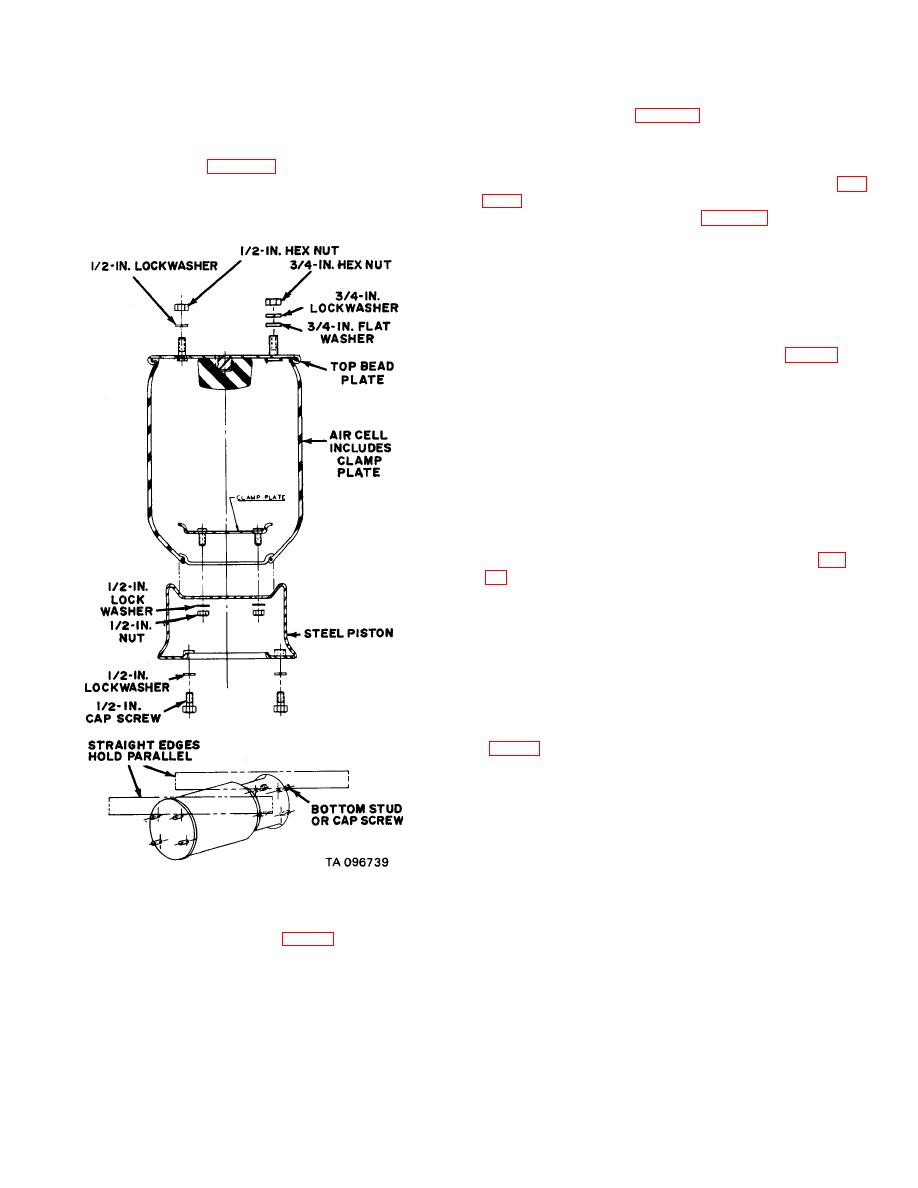

(4) Depress air spring to retract upper

(3) Start the 1/2-inch nuts and lock washers

mounting studs from frame and remove air spring with

on studs inside piston (fig. 4-43). Do not tighten.

lower piston attached.

(4) Rotate piston so that mounting studs in

(5) Turn air spring assembly upside down and

bottom of piston are parallel with mounting studs in top

remove 1/2-inch nuts (fig. 4-43) from inside of piston.

bead plate.

Tap down on clamp plate studs until air cell separates

(5) Start cap screws in bottom of piston (fig.

from piston.

bottom cap screws as shown in fig. 4-43. Adjust piston

studs until straight edges aline.

(6) Tighten nuts inside piston to a torque of

50 lb-ft.

(7) Recheck for proper alignment of top and

bottom studs.

(8) Pressure test at 40 psi and check for

leaks with soap solution.

(9) Place air spring assembly (15, fig. 51) on

pad of equalizing arm and install lower mounting cap

screws (17) and lock washers (13). Tighten to a torque

of 25 lb-ft. maximum.

(10) Depress air spring. Guide upper studs

into air spring mounting plate (14). Secure with nuts (11

and 12), lock washers (10 and 13), and flat washer (9).

Tighten to a torque of 25 lb-ft. maximum.

(11) Reconnect height control valve linkage

and air line (8).

(12) Recheck for leaks at operating pressure.

(13) Remove blocking and jacking equipment.

f.

Removal of Axle Connection Components (fig.

(1) Remove all weight from suspension by

blocking up semitrailer and jacking up axle.

(2) Exhaust all air from air springs by

disconnecting linkage to both height control valves and

rotating actuating arms down.

(3) Remove axle cap nuts (23), flat washers

(22), and bolts (6) and (7) and remove axle connection

components (18 through 21).

g. Installation of Axle Connection Components

CAUTION

The axle connection cap (21) must be

drawn down so that a metal to metal

contact exists

between

the

axle

connection cap and its mating part (16).

Tighten nuts to a torque of 300 lb-ft.

(1) Position axle connection components (18

through 21). Make sure that groove in axle pad (20)

Figure 4-43. Air spring replacement.

matches bottom tongue on axle adapter (19), and that

metal tongues on axle connection cap (21) fit into

e.

Installation of Air Spring (fig. 51).

respective slots provided in mating parts.

(1) Position new air cell, right side up, over

(2) Secure axle connection components (18

piston. Position clamp plate so that studs hang down

through 21) with bolts (6) and (7), flat washers (22) and

through opening in air cell.

nuts (23).

(2) Carefully set air cell down on piston so

(3) Reconnect linkage to height control

that studs go through holes in piston.

valves.

4-63