TM 9-2330-294-14

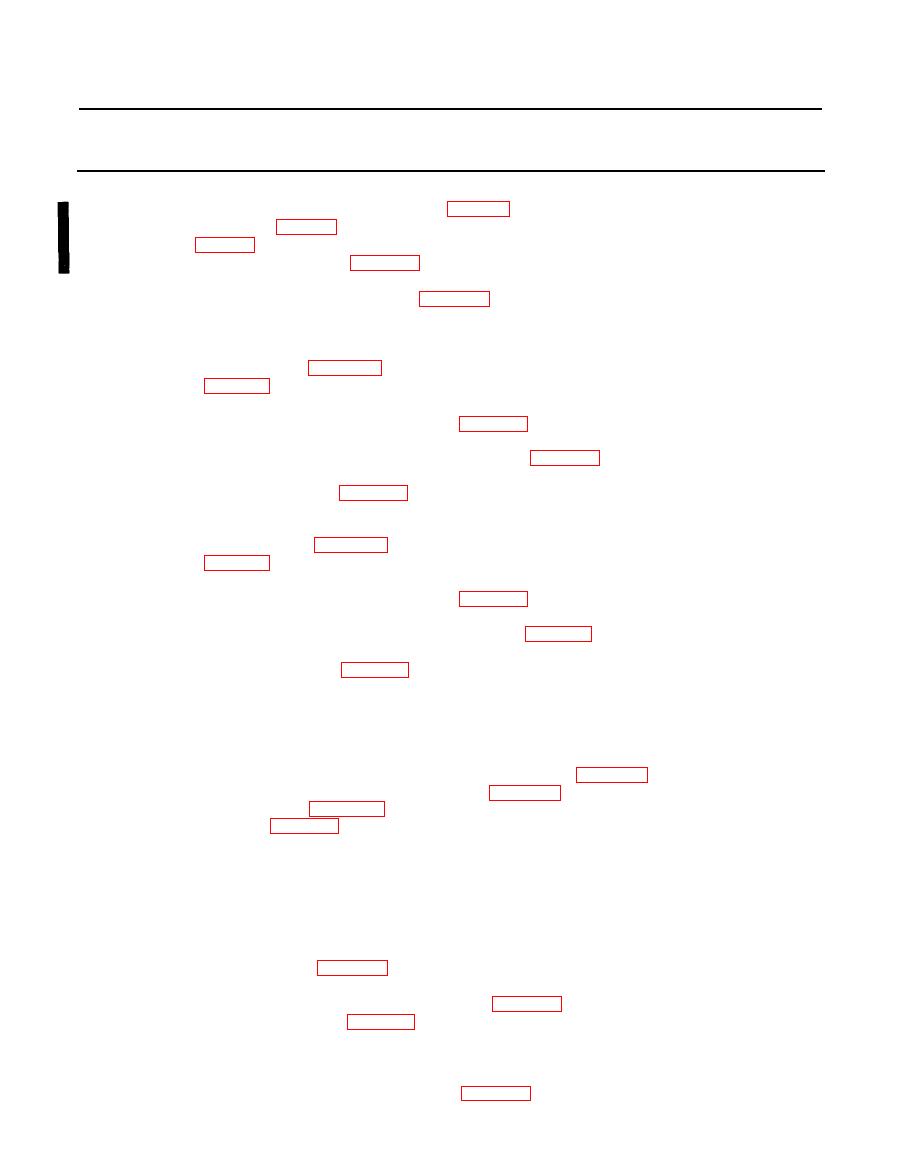

Table 4-4. Troubleshooting Air System Continued

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

13. BRAKES OVERHEAT

Step 1. Check for insufficient lining to drum clearance (para 4-30b(3)).

Adjust brakes (para 4-30b (3)). If this fails inspect, repair or replace automatic adjuster

Step 2. Pull hub(s) and drum(s) (para 4-60) and visually inspect brake mechanism. Apply brake and

observe shoe movement. Shoes should expand and return smoothly.

Replace broken return spring (para 4-31). If shoe action is still not smooth and free

clean brake mechanism parts and reassemble.

14. UNEVEN BRAKES

Step 1. See malfunction 4, step 1.

Adjust brakes (para 4-30b). If this fails inspect, repair or replace automatic adjuster

Step 2. See malfunction 4, step 2.

Replace damaged or plugged air line (para 4-39).

Step 3. See malfunction 4, step 3.

Clean, repair or replace brake mechanism parts (para 4-30 through 4.35).

Step 4. See malfunction 9, step 4.

Replace relay valve (para 4-42)

15. HARD PULLING BRAKES

Step 1. See malfunction 4, step 1.

Adjust brakes ( para 4-30b). If this fails inspect, repair or replace automatic adjuster

Step 2. See malfunction 4, step 2.

Replace damaged or plugged air line (para 4-39).

Step 3. See malfunction 4, step 3.

Clean, repair or replace brake mechanism part (para 4-30 through 4-35).

Step 4. See malfunction 9, step 4.

Replace relay valve (para 4-42).

16. FAIL-SAFE NOT HOLDING

Step 1. Check to see if the power springs are released.

CAUTION

If springs are already fully released, the release bolt may be against its stop so do not use heavy

force if the bolt will not turn. Excessive force can strip the release bolt.

Turn release bolt counterclockwise until a stop is felt (para 4-30d).

Step 2. Check for excessive drum to lining clearance (para 4-30b ).

Adjust brakes (para 4-30b). If this fails inspect, repair, or replace plunger housing

assembly (para 4-35).

Step 3. Check for jammed brake actuators on wheel ends or mud or ice in mechanism.

Expose brakes to warmth. Clean parts of mud and dry all parts.

Step 4. Turn release bolt clockwise. Lack of resistance indicates broken spring or stripped bolt.

If bolt turns clockwise after 25 turns are made, bolt threads are stripped.

CAUTION

Do not force bolt. A stop is built into the fail-safe, and the bolt can be stripped if turned past this

stop .

Replace fail-safe (para 4-32).

17. NO BRAKES WILL RELEASE (SEMITRAILER COUPLED TO TOWING VEHICLE)

Check for defective emergency relay valve (para 4-37f ),

Replace relay valve (para 4-42).

18. BRAKES WILL NOT RELEASE ON SINGLE WHEEL

Step 1. Visually inspect air line in immediate area of locked wheel for dents or breaks. Manually

compress fail-safe; if wheels become free obstruction in air supply is indicated.

Replace damaged or plugged tubing (para 4-39).

Change 1