TM 9-2330-294-14

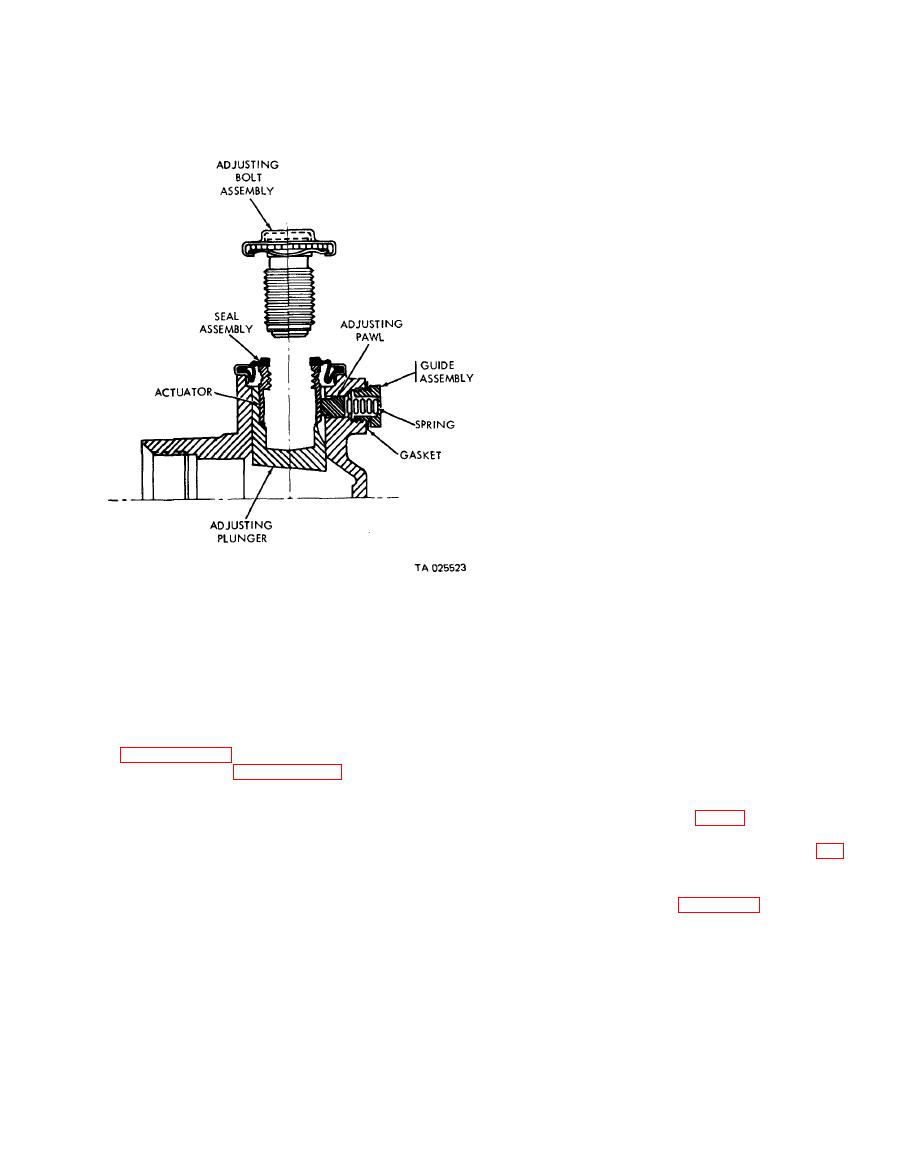

(6) Using driver (CPR 102256) seat seal

assembly into the plunger housing same as (2) (c )

above. Hand tighten guide assembly into the

plunger housing.

(7) Proper meshing of the pawl and actuator

teeth can be checked at this point. Grease-coat

(BRH) adjusting bolt threads and thread adjusting

bolt into the adjusting actuator after working it

through the seal assembly flap hole, being careful

not to pinch the seal in the threads. Thread ad-

justing bolt into the actuator until it bottoms. A

clicking sound and a ratcheting feel will indicate

meshing of the teeth. Turn the adjusting bolt out

three turns. Proper meshing is indicated if there is no

clicking sound or ratcheting feel.

(8) Tighten guide assembly to 15-20 lb ft

(9) Turn adjusting bolt in to just short of the

seal assembly. Do not bottom it on the seal. Pull the

adjusting bolt and actuator outward slightly against

the seal, to insure entry of the seal lip in the actuator

groove. Push the bolt and sleeve back into the

plunger.

f. Installation. Install new or repaired plunger

housing assembly in reverse order of removal

(b above). Take care to install right-hand and left.

hand assemblies on proper side of semitrailer.

Section VIII. AIR SYSTEM MAINTENANCE

towing vehicle air system is operating

4-36 General

properly.

The air system includes lines, fittings, valves,

(1) Air pressure check. Prior to making the

controls, and reservoir necessary to operate the air

following checks and tests be sure good connections

brake and air suspension systems. Refer to

are made at the air supply couplings from the towing

vehicle. Allow approximately 10 minutes for the

system. Refer to paragraph 4-52 for a description of

trailer air system to become fullycharged. Install

the air suspension air system.

accurate tire gage (recently calibrated) on tank valve

of auxiliary air supply valve (fig. 2-8). Assure that

Conjunction with Troubleshooting

system air pressure is at 90.120 psi. (Same reading

a. General. The following procedures briefly

should be obtained at tank valve at air tank fill (fig.

outline steps necessary to isolate malfunctions. This

2-3) ). If air pressure is low, check emergency and

paragraph also includes individual air system

reservoir air line tubing for kinks and listen for

component tests necessary for troubleshooting. All

leakage (d below). Refer to figure 4-27 and 4-28 to

tests for valves are on-vehicle, in-system tests.

identify air lines.

Valves shold not be removed unless they are to be

(2) Test while driving. Tow vehicle short

replaced.

distance while observers are stationed along roadside

b. Brake Air System Checks.

at sides of trailer, Perform test first with front

NOTE

suspension raised, then with rear suspension raised.

No testa should be made on the semitrailer

If brakes fail (no wheel skid observed), or if brakes

air system until you make sure that the

pull, grab, are weak, uneven, slow in application, or