TM 9-2330-294-14

d. Inspection and Repair. Thoroughly clean all

metal parts with dry cleaning solvent type II (SD-2)

and dry with low pressure compressed air.

NOTE

Do not use dry cleaning solvent to clean any

rubber parts.

Thoroughly clean seal assemblies and gaskets with

mild soap solution and dry with low pressure

compressed air. Wire brush plunger parts and ad-

justing bolt threads, if required, to remove caked-on

dirt and corrosion. Inspect seal assemblies and

gaskets for tears, cuts and deterioration, and replace

if damaged. Check the angled plunger roller faces for

pits, nicks or grooves, and replace if necessary.

Check anchor plunger nose for burrs, and remove

with crocus cloth, if necessary. A bright, shiny

surface where wedge assembly roller contacts

plunger surface is normal. Check threads of ad-

justing bolt assembly and replace assembly if

damaged.

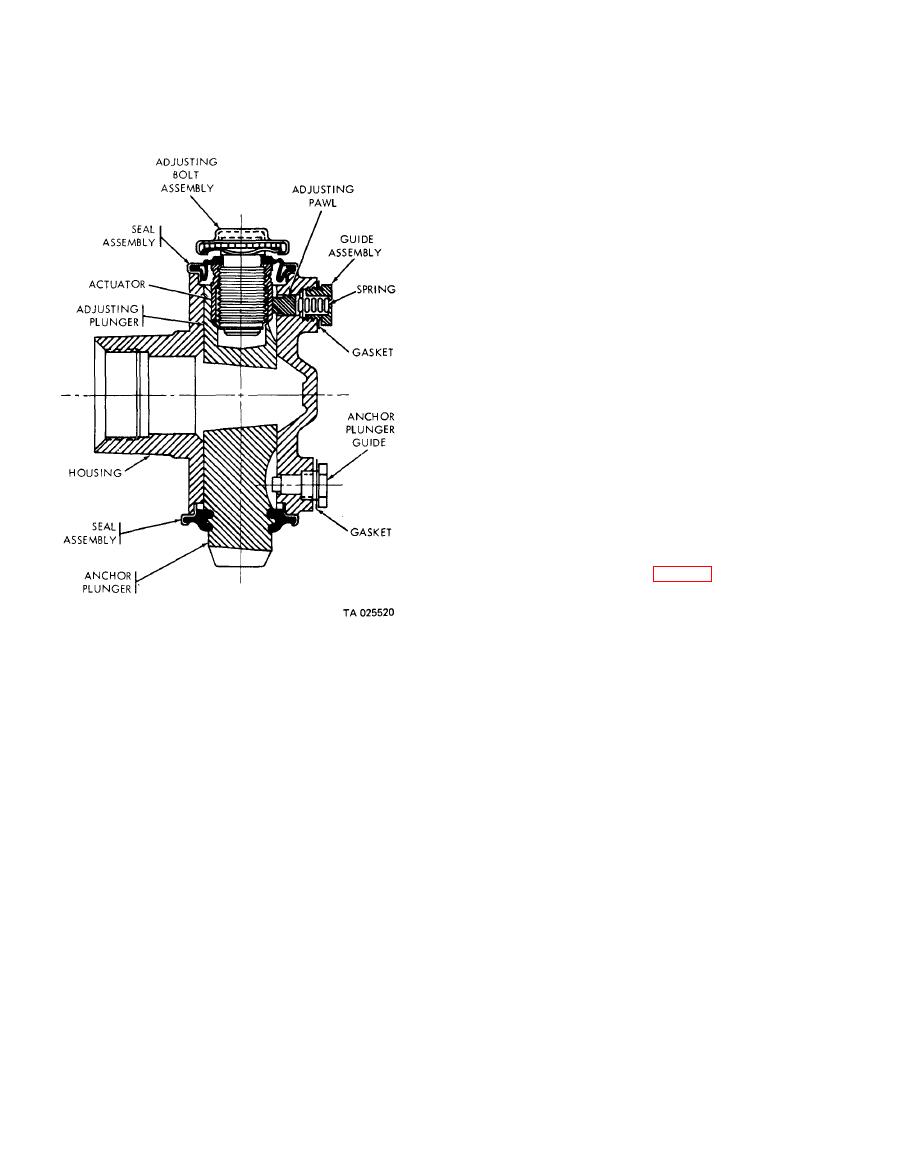

e. Assembly.

.

NOTE

Each plunger housing assembly has one

adjusting plunger and one anchor plunger.

The anchor plunger is marked on the slotted

end, "R" for right-band brakes and "L" for

left-hand brakes. DO NOT mix at assembly.

(1) Assemble seal assembly onto anchor

plunger in the following manner (fig. 4-38):

Figure 4-37. Plunger housing assembly (semitrailer No. 201

and on ).