TM 9-2330-358-14

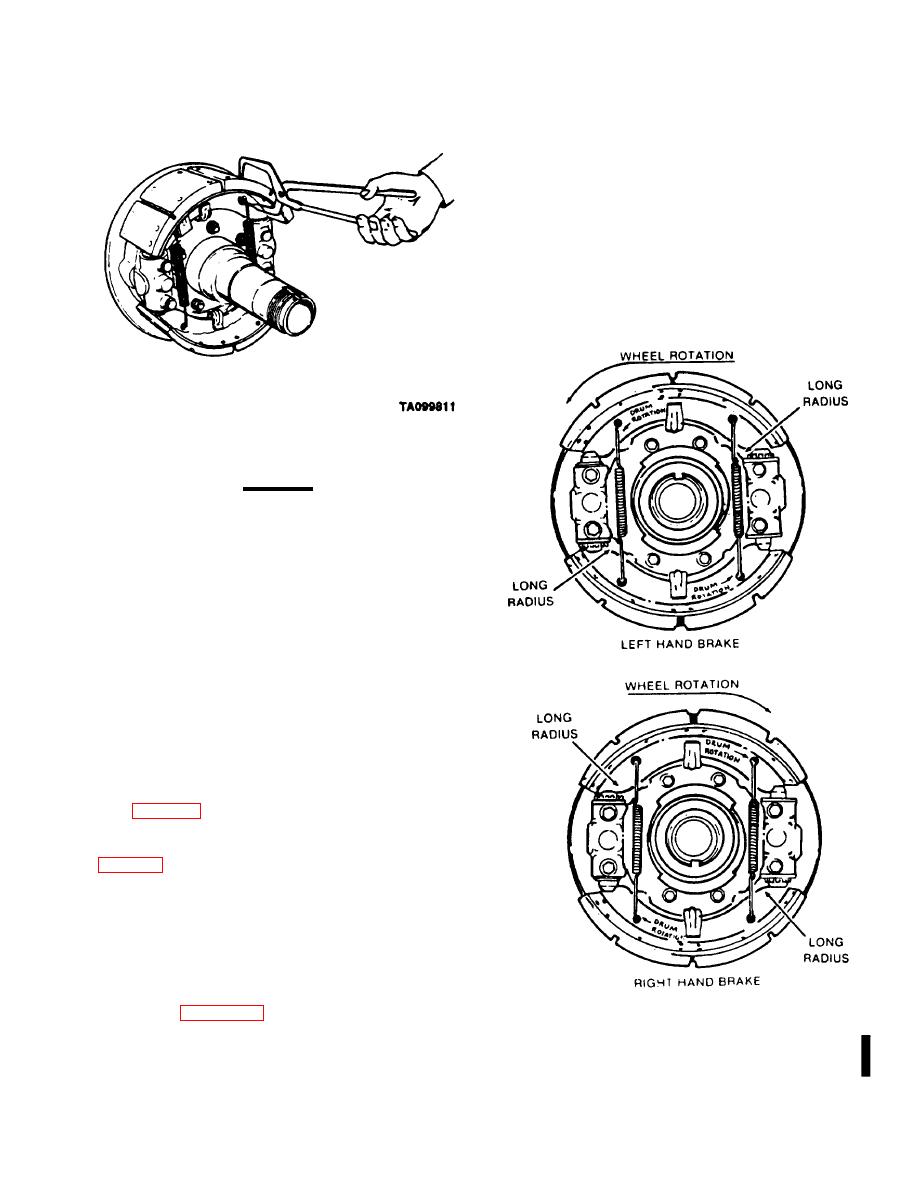

(2) The anchor (solid) plunger must be

positioned at the trailing end of each shoe. The adjustable

plungers must be installed at the leading end of the shoes.

This lets the brake torque be absorbed by the anchor

plunger during forward wheel rotation.

(3) The long radius on the brake shoe should be

engaged with the adjustable plungers.

(4) Install new return springs whenever new or

relined brake shoes are being installed.

Figure 4-60. Remove Brake Shoes.

CAUTION

Use an authorized suitable solvent to clean

the brake components. DO NOT use gasoline

or hot water solutions. Gasoline coats the

metal parts and prevents grease from

adhering. Water causes etching and rust If

parts are not dried completely.

(5) Clean brake shoe return springs, backing

plate, and wedge assemblies.

(6) Do not remove the dust shield unless damage

is evident.

d.

Repair.

(1) Service the plungers and brake adjusting

parts (para 4-36).

the brake wedge assemblies

(2) Service

(3) Refer replacement of brake linings and

refacing of the drums to direct support maintenance.

Installation.

e.

(1) It is imperative that each brake be assembled

as shown in figure 4-61 in relation to forward wheel

rotation. Note the position of the solid plunger and the

adjusting plunger. Also note the position of the long

M970 except M970 SN TC-0843, TC-0844, and TC-103 thru

radius on the shoe web.

TC-178).

Change 3

4-81