TM 9-2330-356-14

Brake Wedge Assembly, M967, M969, and

WARNING

M970 except M970 SN TC-0843, TC-0844,

and TC-103 thru TC-178 (Fig. 4-64).

Dry cleaning solvent P-D-680 is toxic and

Always

CAUTION

flammable.

wear protective

goggles and gloves, and use only in l

well-ventilated area. Avoid contact with

Before removing any wedge actuator or at-

skin, eyes, and clothes, and DO NOT

tempting to release spring brake or removing

breathe vapors. DO NOT use near open

a clamp band, block wheels to prevent ve-

flame or excessive heat. The solvent's

hicle movement.

flash point la 1OOF-138F (38C-59C).

If you become dizzy while using cleaning

a.

Removal.

solvent, immediately get fresh air and

medical help. If solvent contacts eyes,

(1) Remove brake air chamber (paras 4-37 and

Immediately wash your eyes with water

4-39),

and get medical aid.

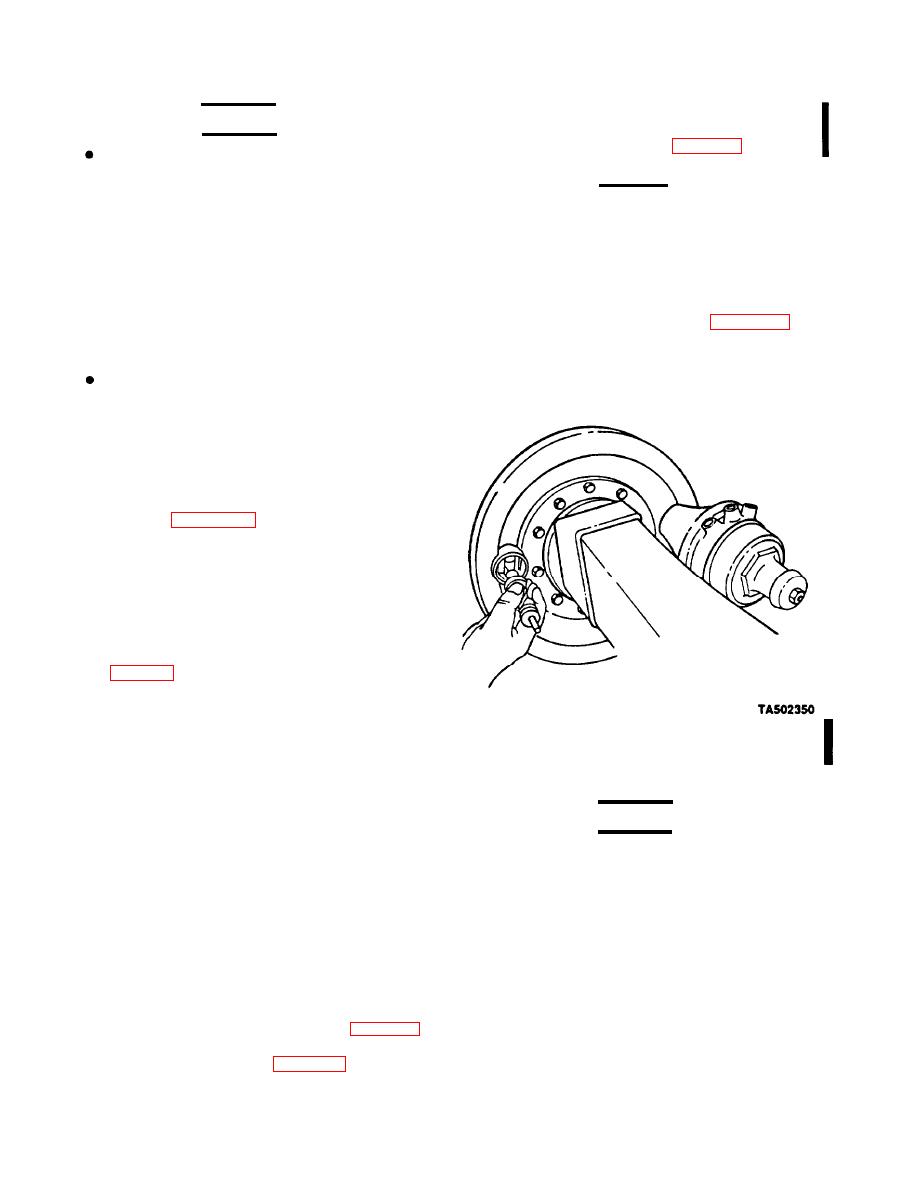

(2) Remove wedge assembly by pulling it straight

Compressed air used for drying or

out of plunger housing.

clearing purposes must not exceed 30 psi

(207 kPa). Wear protective clothing

(goggles and gloves) and use caution to

avoid injury to personnel.

(10) Clean anchor pins, rollers, roller retainers,

spring pins, and brake shoe return spring with dry cleaning

solvent (item 11, Appendix E). Dry the parts with low

pressure compressed air.

(11) Refer replacement of brake linings and

refacing of the drums to direct support maintenance.

d.

Installation.

(1) Install spider bolt, washer, and nut. Do not

tighten (fig. 4-63).

(2) Install spring pins cm brake shoes.

(M967, M969, and M970 except M970 SN TC-0843,

(3) Install rollers and roller retainers on brake

TC-0844, and TC-103 thru TC-178).

shoes.

b.

Inspection.

(4) Place brake shoes into position on brake

spider, and install upper and lower anchor pins and anchor

WARNING

pin washers.

Compressed air used for drying or cleaning

(5) Install anchor pin retaining rings on upper

purposes must not exceed 30 psi (207 kPa).

and lower anchor pins.

Wear protective clothing (goggles and

gloves) and use caution to avoid Injury to per-

(6) Using brake spring pliers, install brake shoe

sonnel.

return spring.

(1) Clean wedge assembly thoroughly with mild

(7) Tighten spider nut and bolt to 100-120 lb.-ft.

soap solution and dry with low pressure compressed air.

e.

Assembly and Adjustment.

(2) Inspect for damaged rubber boot, roller

retaining cage, rollers, or broken spring.

(1) Install wheel and drum assembly (para 4-49).

(3) Replace wedge assembly if damaged or

broken.

(2) Adjust slack adjuster (para 4-34).

Change 3