TM 9-2330-356-14

(2) Inspect brake linings for damage and wear.

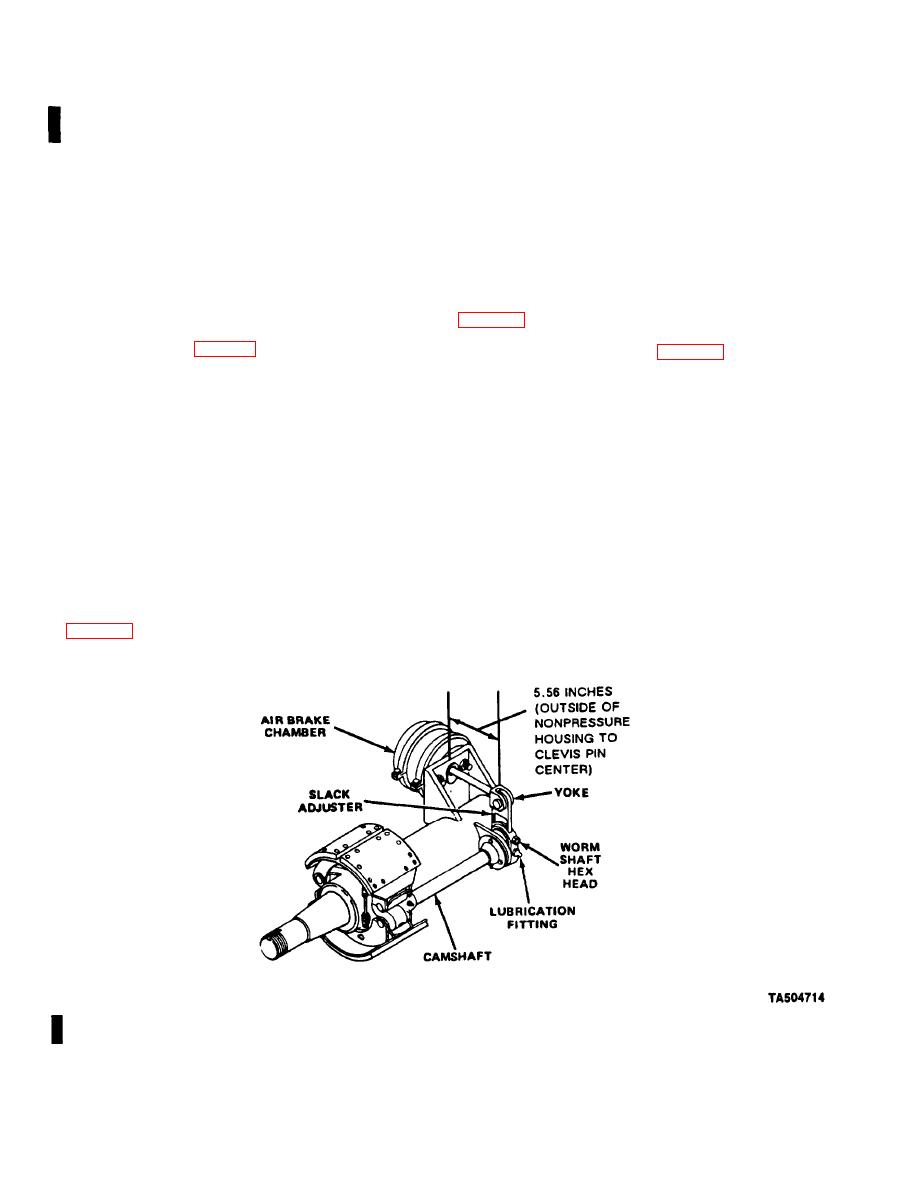

M969A1, and M970A1 including M970 SN TC-0843,

New lining has approximately) -inch of stock above

TC-0844, and TC-103 thru TC-178.

center rivets and approximately -inch of stock above end

a

Test and Adjustment.

rivets. Replace brake shoe if lining is damaged or worn

within .030-inch of rivet heads. By recording lining wear

(1) Jack up semitrailer to lift all wheels off the

between scheduled annual brake maintenance periods,

ground. Block the frame securely.

expected wear can be calculated. Shoes with linings that

will not last until the next scheduled maintenance interval

(2) Release all spring forces from slack adjuster

should be replaced.

and camshaft by applying air to the air brake chamber.

c.

Removal.

(3) Check that the wheels rotate freely.

( 1 ) Remove wheel and drum assembly

(4) Check yoke adjustment. Dimension from

outside of nonpressure housing to center of clevis pin

must be 5.56-inches (fig. 4-62).

(2) Loosen spider bolt (fig. 4-63).

(5) Apply a 9/16-inch wrench to worm shaft hex

(3) Using broke spring pliers, remove broke shoe

head and push in against the slack adjuster to unlock the

return spring.

worm shaft.

(4) Remove anchor pin retaining rings and

(6) Turn the hex head of the worm shaft

anchor pin washers.

clockwise on slack adjuster until wheels cannot be turned.

(5) Drive upper and lower anchor pins from rear

(7) Back off the worm shaft until the wheel turns

of brake shoe.

freely.

(6) Remove brake shoes.

(8) Repeat steps (1) through (7) for all four brake

assemblies.

(7) Remove roller retainers and rollers from

brake shoes.

b.

Inspection and Replacement.

(8) Remove spring pins from brake shoes.

(1) Remove wheel and drum assembly

(9) Remove brake spider nut, washer, and bolt.

Figure 4-62. Adjustment of Yoke and Slack Adjuster (M967A1, M969A1, and M970A1 including M970 SN TC-0843,

TC-0844, and TC-103 thru TC-178).

Change 3